How big an inverter is needed for a 60v voltage

60V Pro 300 Watt Inverter The GREENWORKS® Pro 60V power inverter provides 300 watts of continuous power whenever and wherever it''''s needed. With a 230V power outlet and two

Auto Inverter with 60v across ground will not run switching

Apr 3, 2021 · The inverter has a common inverter setup where Neutral/Ground is 60v, Hot/Ground is 60v/ and Neutral/Ground is 120v. So my guess is that the the switching power supply does

Which is better 60v or 24 volt inverter

Is a 24V inverter better than a battery? A 24V inverter, on the other hand, can handle higher power loads, often up to 3,000 watts or more, with a more efficient current draw. Because the

How Big an Inverter Can Be Installed for 60V Voltage

Installing the right inverter size for a 60V system is critical for maximizing energy efficiency and system longevity. Whether you''re designing a solar power setup, an industrial backup system,

Understanding inverters with 60 volts on hot and neutral

Jan 13, 2025 · These cheap portable inverters are designed to be floating (no ground), and must remain floating, or will be damaged. You are reading 60v to ground, because they are floating.

Understanding inverter startup voltage.

Jun 4, 2021 · This converter is most of the inverter''s idle power consumption and can be in range of 40-50 watts of overhead power. The actual PV charge controller producing HV DC output

How Many Volts Does a Photovoltaic Panel Generate? Let''s

Future-Proofing: High-Voltage Solar Arrays The industry''s buzzing about 1500V systems – the voltage heavyweight champions. These setups reduce installation costs by 15-20% for utility

Understanding inverters with 60 volts on hot and neutral

Jan 13, 2025 · I understand electricity fairly well, however I have not been able to find much online regarding portable inverters using 60 volts on opposing phases on both hot and neutral.

Solar Panel Output Voltage: How Many Volts Do

2 days ago · For many calculations, we will need to know how many volts do solar panels produce. It''s not all that easy to find the solar panel output voltage;

12v or 60v Inverter. Does it Matter? | Electronics Forum

Dec 9, 2020 · Every time that the power has to be converted, you waste energy. That''s because each conversion is not 100% efficient. So, for the sake of maximizing the system efficiency, get

How Long Does a 60V Inverter Battery Last Key Factors Tips

Wondering how long your 60V inverter battery can power your devices? The runtime depends on capacity, load, and usage patterns. This guide breaks down real-world scenarios and

What Can a 600W Inverter Run? The Ultimate Guide to 600 Watt Inverters

Jun 9, 2025 · Discover what a 600w inverter can run, from laptops to small appliances. Learn usage tips, battery needs, and best practices for off-grid or backup power.

How Many Volts Does a Lawn Mower Battery Need?

Apr 30, 2025 · A higher Ah rating translates to a larger battery capacity and longer runtimes. For example, a 60V battery with a 5Ah capacity will provide 5 hours of power at a constant 60

Watts, Amps, Volts Explained – Simple Electrical

Mar 12, 2025 · Crucial for matching inverter size to appliance demand Ignoring any part of the volts amps watts relationship leads to undersized wire, tripped

Inverter Battery Voltage: How Many Volts Are Needed For

Mar 27, 2025 · According to a report by Energy Statistics (2022), approximately 60% of inverter setups in homes utilize 12V batteries due to their affordability and ease of installation. The 24V

Understanding inverter voltage

Jan 10, 2024 · Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function

Understanding the Positive and Negative of a 60 Volt Inverter

When evaluating the positive and negative of a 60 volt inverter, it''s essential to balance technical specifications with real-world applications. These inverters are widely used in renewable

Amps or Volts, or Does it matter

Oct 11, 2023 · If it''s 30 volts and 20 amps, this is 600 watts, it will output 600 watts at 12 volts and 50 amps. If its 60 volts in and 10 amps, still 6000 watts, the output will be 12 volts and 50 amps.

12v or 60v Inverter. Does it Matter? | Electronics Forums

Dec 9, 2020 · Hello! I''m in the middle of a build. It''s a lithium battery pack ( aka solar generator). The plans called for 60 volt 2500 watt DC>AC inverter. I accidentally bought a 12 volt. The

Inverter Battery Voltage: How Many Volts Are Needed For

Mar 27, 2025 · An inverter battery typically operates at 12V, 24V, or 48V. These voltages represent the nominal direct current (DC) needed for the inverter''s function.

12v or 60v Inverter. Does it Matter? | Electronics Forum

Dec 9, 2020 · Hello! I''m in the middle of a build. It''s a lithium battery pack ( aka solar generator). The plans called for 60 volt 2500 watt DC>AC inverter. I accidentally bought a 12 volt. The

6 FAQs about [Does it matter how many volts a 60v inverter turns ]

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

What voltage is a 12V inverter?

Inverters come in various configurations, each designed for specific power systems. Common rated input voltages include 12V, 24V, and 48V. The choice depends on the application, the size of the power system, and the available power source. A 12V inverter is commonly used for smaller applications, such as in vehicles or small off-grid setups.

Do AC appliances need a 120 volt inverter?

Our batteries come in different voltages (12,24, & 48v) But AC appliances required 120 volts (because our grid power comes in 120 volts). So an inverter will convert the lower voltage of the battery into 120 volts in order to run AC appliances

What is the cut off voltage on a 12V inverter?

For a 12V inverter, the cut-off inverter voltage is often set around 9.5VDC. Dropping below this threshold triggers a shut-off mechanism to preserve the battery's health and longevity. How do you check the voltage on an inverter?

What is a safe voltage for a 12V inverter?

For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate fluctuations in the power source and protect the inverter from potential damage. What happens if voltage is too high for inverter?

Why is inverter voltage important?

In the realm of power electronics, the inverter voltage is a critical parameter that dictates its performance, compatibility, and safety. Understanding the intricacies of inverter voltage is essential for anyone seeking a reliable and efficient power supply.

Learn More

- How many volts can the inverter convert to 220

- How many volts does the inverter output voltage change

- 60v inverter turns

- How many watts is suitable for a 60V power frequency inverter

- How many volts inverter do I need for a 68v battery

- How many volts are normal for charging the base station power supply

- How much capacity does a 12v inverter use

- How much does a 26kw inverter cost

- How is the photovoltaic power generation of the Sri Lanka communication base station inverter

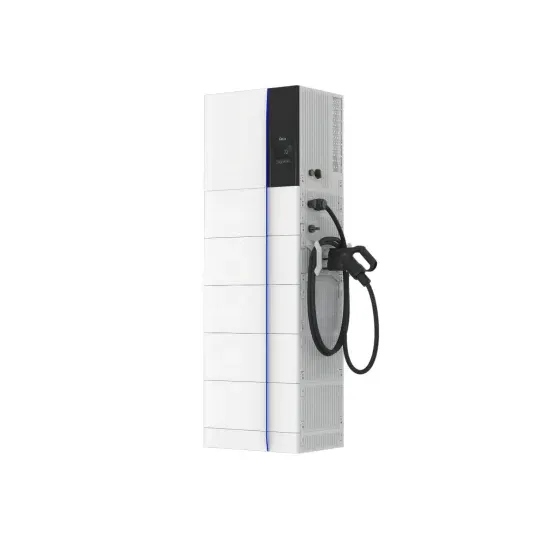

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.