Battery Grade Graphite Anode Market

Feb 25, 2025 · Over 70% of battery-grade graphite is consumed by lithium-ion batteries for EVs, with global EV sales projected to exceed 40 million units annually by 2030. For instance,

Assessing Reaction Mechanisms of Graphite Negative

Apr 7, 2021 · In such batteries, graphite is typically used as the negative electrode and the present work examined the reaction mechanisms at graphite negative electrodes based on

Nb1.60Ti0.32W0.08O5−δ as negative electrode active

Oct 12, 2024 · All-solid-state batteries (ASSB) are designed to address the limitations of conventional lithium ion batteries. Here, authors developed a Nb1.60Ti0.32W0.08O5-δ

Graphite Electrode Historical Prices, Graph – Asian Metal

Home> Carbon> Graphite Electrode>Graphite Electrode Price Index Carbon More: Product Specification Unit Price Price in USD* Change Update FCST Graphite Electrode R.P.

Graphite Anode Material For Lithium Ion Battery

During the charging process, the graphite negative electrode accepts lithium ions embedded, and during the discharging process, it releases the lithium ions. The theoretical capacity of graphite

Practical application of graphite in lithium-ion batteries

Sep 20, 2024 · This review aims to inspire new ideas for practical applications and rational design of next-generation graphite-based electrodes, contributing to the advancement of lithium-ion

Negative Electrode Materials For Lithium Ion Battery Market

Negative-electrode Materials for Lithium Ion Battery Market Overview: The Negative-electrode Materials for Lithium Ion Battery market is expected to register a significant revenue CAGR

Enhanced specific energy in fast-charging lithium-ion batteries

Jul 7, 2025 · Developing lithium-ion batteries with high specific energy and fast-charging capability requires overcoming the potential-capacity trade-off in negative electrodes.

Global Negative-electrode Materials for Lithium Ion Battery

The Negative-electrode Materials for Lithium Ion Battery market size, estimations, and forecasts are provided in terms of output/shipments (Tons) and revenue ($ millions), considering 2022

Global Negative-electrode Materials for Lithium Ion Battery

Feb 8, 2024 · Negative-electrode materials, typically composed of materials like graphite or silicon, are integral components of lithium-ion batteries. These materials play a crucial role in

UHP Graphite Electrode (600MM) Price Trend, Index, Chart

Procurement Resource provides latest UHP Graphite Electrode (600MM) prices and a graphing tool to track prices over time, compare prices across countries, and customize price data.

High-capacity, fast-charging and long-life magnesium/black

Oct 7, 2024 · Here, to circumvent these issues, authors report the preparation of a magnesium/black phosphorus composite and its use as a negative electrode for non-aqueous

A direct method to quantify lithium plating on graphite

May 9, 2023 · The deposition of metallic lithium is a degradation mechanism, also known as lithium plating, that might occur at the negative electrode surface of Li-ion battery cell,

Aluminum foil negative electrodes with multiphase

Jul 18, 2023 · Aluminum-based negative electrodes could enable high-energy-density batteries, but their charge storage performance is limited. Here, the authors show that dense aluminum

China Communication Base Stations Factory and

Jun 4, 2025 · Reinforced graphite sheet gasket for led producing from china Graphite electrode & nipples, good price edm graphite electrodes Good Wholesale Vendors Rp 300 Graphite

Lithium battery graphite negative electrode material price

Practical application of graphite in lithium-ion batteries: When used as negative electrode material, graphite exhibits good electrical conductivity, a high reversible lithium storage

Battery pack price increases at different battery-grade graphite price

Aug 14, 2025 · Percentages show increase in total battery price. Base graphite price is global average battery-grade anode material in 2023. Battery pack price increases at different battery

WO/2025/118620 GRAPHITE NEGATIVE ELECTRODE ACTIVE

Jul 19, 2024 · A graphite negative electrode active material and a preparation method therefor, a negative electrode sheet containing same, a secondary battery, and an electric device. A

High-performance graphite negative electrode in a

Apr 1, 2013 · These results suggest that EMImFSI is a suitable electrolyte for lithium-ion batteries utilizing graphite negative electrodes and that optimization of the electrolyte composition with

Graphite as an Anode Material in Sodium-Ion Batteries

Dec 9, 2022 · Today, graphite is by far the most used material for the negative electrode material in lithium-ion batteries (LIBs). At first sight, the use of graphite in sodium-ion batteries (SIBs)

Battery Carbon-based Negative Electrode Materials Market

Global Battery Carbon-based Negative Electrode Materials Market Size was estimated at USD 76400 million in 2022 and is projected to reach USD 133147.53 million by 2028, exhibiting a

Advanced rechargeable aluminium ion battery with a high

Feb 13, 2017 · Here the authors reveal high-quality natural graphite as a promising cathode for Al-ion batteries, also identifying chloroaluminate anion intercalation in graphite by Raman

Graphite Electrode Historical Prices, Graph – Asian Metal

Asian Metal provides Graphite Electrode Prices IndexSpecification Unit Price Price in USD* Change Update FCST Graphite Electrode R.P. D400mm EXW China RMB/mt Sign in to view

Charge–discharge behavior of graphite negative electrodes

Nov 1, 2013 · Charge–discharge behavior of graphite negative electrodes in bis (fluorosulfonyl)imide-based ionic liquid and structural aspects of their electrode/electrolyte

Negative-electrode Materials for Lithium Ion Battery Market

Graphite remains the most widely used material for negative electrodes in lithium-ion batteries due to its excellent electrical conductivity and intercalation capabilities. However, emerging

Advancing lithium metal electrode beyond 99.9% coulombic

May 7, 2025 · Lithium metal negative electrode is pivotal for advancing high-energy-density lithium batteries. Despite their promise, the inherent poor interfacial stability of electrolytes on

Electrochemistry and morphology of graphite negative electrodes

Oct 10, 2019 · State-of-the-art lithium-ion batteries (LIBs) contain a graphite negative electrode and a transition-metal-oxide positive electrode. Owing to their high energy density, LIBs

Lithium-ion batteries – Current state of the art and

Dec 15, 2020 · Schematic illustration of the state-of-the-art lithium-ion battery chemistry with a composite of graphite and SiOxas active material for the negative electrode (note that SiOxis

6 FAQs about [Communication base station graphite battery negative electrode price]

What is graphite anode material for lithium-ion batteries?

The graphite anode material for lithium-ion batteries uses a crystalline layered graphite-based carbon material. It works in synergy with the cathode material to achieve multiple charging and discharging of the lithium-ion battery.

How does a graphite negative electrode work?

During the charging process, the graphite negative electrode accepts lithium ions embedded, and during the discharging process, it releases the lithium ions. The theoretical capacity of graphite-based anode materials is 372 (mA • h) / g, grayish black or steel gray, with metallic luster.

What is the theoretical capacity of graphite based anode materials?

The theoretical capacity of graphite-based anode materials is 372 (mA • h) / g, grayish black or steel gray, with metallic luster. Graphite anode materials for lithium ion batteries are divided into three categories: natural graphite, artificial graphite, and composite graphite.

Why were the graphite electrodes markets quiet in China?

The graphite electrodes markets in China remained quiet in the two weeks ended Wednesday May 10 due to slow liquidity resulting from weak steelmaking sectors both at home and abroad How can we help you?

Why is graphite a challenge in the graphic market?

Exponential growth from the electric vehicle sector has propelled the industry’s graphite requirements and created challenges for in the graphic market. Various widely-used lithium-ion batteries – from LFP to NCM cathodes – use graphite anodes.

Why should I subscribe to our graphite insights?

Our reporters and researchers cover the advantages and disadvantages of synthetic versus natural graphite, and provide price data, outlooks and insights into the supply-demand balance. Subscribing to our graphite insights will give you access to: Ask about our products today

Learn More

- Communication base station graphite production lithium battery negative electrode

- Bhutan outdoor communication battery cabinet installation price base station

- Battery cabinet communication base station price

- Liberia communication base station battery equipment price

- Cairo communication base station lead-acid battery price

- Brunei outdoor communication battery cabinet price base station

- Vienna Communication Base Station Battery Cabinet Spot Price

- Maintenance of battery energy storage system for integrated communication base station in Belize

- What qualifications are required for communication base station battery energy storage systems

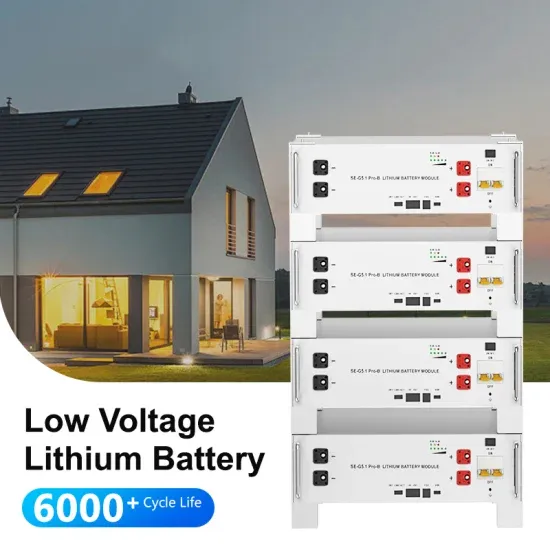

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.