Solar panels are placed next to the storage container

Best Solar Panels on Shipping Container High-Efficiency 2023 The top-rated Solar Panels on Shipping Container in 2023. Maximize energy efficiency and sustainability with our expert

Solar Panels on Containers: The Ultimate Guide to

Ever thought your old shipping container could power your business while slashing energy bills? Solar panels on containers are revolutionizing how companies approach portable power

A product that has attracted worldwide attention – Folding

Apr 28, 2025 · Collapsible solar Container hit the headlines at recent trade fairs with the latest generation of portable solar technology combining standard shipping containers and

How to Install Solar Panels on a Cargo Container

Oct 24, 2017 · The solar panels were welded to the top of the cargo container, and the video will highlights how to determine where to place each solar panel

Solar-Powered Container Conversions

Installing solar panels on shipping containers is a sustainable and practical solution for powering container conversions, especially in remote, off-grid locations or for those seeking eco-friendly

Are Folding Solar Panels Any Good? What to Know Before

Jun 4, 2025 · Are folding solar panels practical? especially when integrated into folding solar containers, which rely on them to deliver sustained power in off-grid or mobile uses.

Shipping Container Solar Panel Kits Archives

Aug 19, 2025 · Get in on the action with our solar panels for shipping containers! Solar panels for containers from Sunstore contains everything necessary to fit

How to Install Solar Panels on a Cargo Container

Oct 24, 2017 · Learn how to install solar panels on a cargo container roof. This video will provide you with a guide to building a portable power source with a

Mastering the Art of Vertical Packing for Photovoltaic Panels:

May 14, 2025 · Vertical packing is the stacking of PV modules on vertical racks in a shipping trailer or container. The key features are: Rail & Hinge Systems: Heavy-duty rails transport

Solar panels that can be placed in storage containers

Solar Panels on Shipping Containers Explained! Solar panels can be easily integrated onto the roof of a shipping container, providing a substantial amount of energy without taking up

6 FAQs about [PV panels placed on containers]

What is a shipping container solar panel kit?

Typically, a shipping container solar panel kit consists of the following components: Solar Panels: High-quality photovoltaic panels capable of converting sunlight into electrical energy. Mounting and Racking System: Secure structures to mount the solar panels on the container’s roof or sides.

Can solar panels be mounted on shipping containers?

Mounting solar panels on shipping containers is becoming increasingly popular. As photovoltaic panels become lighter and more affordable, and interest in renewable energy grows, more people are turning to solar-powered container solutions.

How many solar panels can fit in a 20-foot shipping container?

The number of solar panels that can fit in a 20-foot shipping container depends on various factors, such as the size of the solar panels and the desired configuration. It is recommended to consult with solar panel professionals or suppliers to determine the optimal number of panels based on the specific dimensions and requirements of the container.

How do you mount solar panels on a shipping container roof?

Mounting solar panels on shipping container roofs or sides requires robust and secure attachment mechanisms. Here are some common methods: Bolted Connections: Utilizing pre-drilled holes in the container’s roof or sides, solar panel mounting brackets can be securely bolted to ensure a stable and durable installation.

How to optimize solar power generation from shipping container installations?

Several factors should be considered to optimize solar power generation from shipping container installations. Adjusting the tilt angle and orientation of solar panels helps maximize sunlight exposure, enhancing energy production.

What are the advantages of shipping container solar?

Modularity is a key advantage of shipping container solar installations. Solar panels can be installed modularly, allowing for easy expansion or reconfiguration as power demands increase or location requirements change. This scalability ensures that solar power systems adapt to evolving needs and circumstances.

Learn More

- Solar PV panels looking for buyers

- There are solar panels and containers on the roof

- Solar panels and power storage containers connected

- Outdoor solar panels can be seen in power storage containers

- Solar panels transformed into photovoltaic containers

- PV panels and connected to inverter

- Middle East Solar PV Panels

- Photovoltaic solar panels with power storage containers

- Are Damascus glass photovoltaic panels good

Industrial & Commercial Energy Storage Market Growth

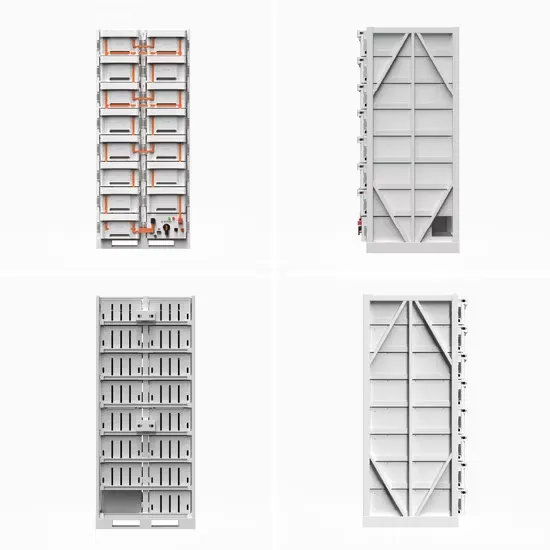

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.