Grid-Connected Micro Solar inverter Implement Using a

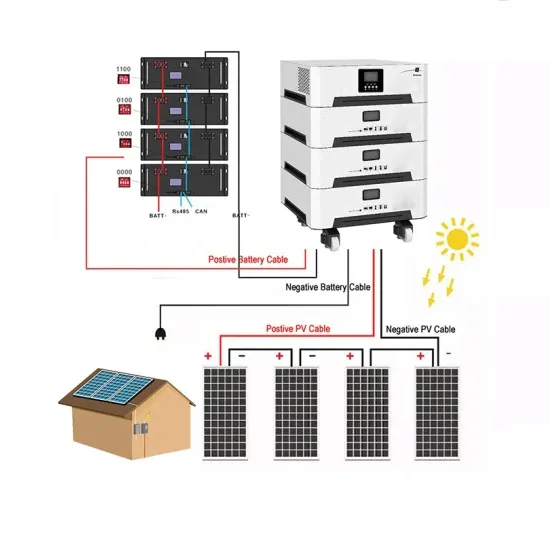

Apr 1, 2023 · The off-grid solar inverter system is mainly used in composition-independent photovoltaic power generation system, applied in the family, the countryside, island, and

Photovoltaic inverter auxiliary products

Photovoltaic systems are continually evolving to improve their efficiency and financial viability. One trend is to move to larger strings of cells giving higher dc voltages to be converted to ac

ISOP Multimode Flyback Based Auxiliary Power Module

Jan 3, 2024 · To address this issue, this paper proposes an input-series-output-parallel (ISOP) configuration based flyback APM, which can effectively reduce the primary voltage stress and

Micro Solar Inverter

Feb 12, 2015 · A vital part of this development is photovoltaic power generation, which uses solar inverters. In all of the solar inverters, the micro solar inverters have been an important

Photovoltaic inverter secondary power supply

This article presents a new auxiliary power supply design for micro inverter based on LMR38020 Fly-BuckTM, with advantages of ease of design, low counts of components in BOM, low cost,

Photovoltaic inverter auxiliary circuit explanation

What auxiliary power does a Micro solar inverter need? Figure 8. In a micro solar inverter,we need auxiliary power that can output multiple voltagesto A/D sample circuits,drive circuits,MCU

Auxiliary Power Supply Design Based on LMR38020 Fly

Aug 31, 2023 · Usually installed under the PV panel, micro inverter is required to have high power conversion efficiency, good thermal performance, small size and long lifetime. The

Design of Auxiliary Power Supply for the Solar PV Inverter

Jan 19, 2023 · This paper the characteristics of the auxiliary power of photovoltaic inverter power supply, design a kind of isolated single-ended anti-flyback multiplex output switching power

Auxiliary Power Supply Design Based on LMR38020 Fly

Aug 31, 2023 · ABSTRACT Solar Micro Inverter is able to help the solar photovoltaic PV system to achieve per-panel level Maximum Power Point Tracking (MPPT) to improve power yield

Considerations for auxiliary flyback power supplies (Rev. A)

Sep 6, 2024 · Auxiliary flyback supplies in industrial applications A solar string inverter converts the DC voltage generated from photovoltaic panels to AC grid power. To accomplish this,

太阳能微型逆变器中基于 LMR38020 Fly-Buck 的辅助电源设 计

Sep 5, 2023 · 太阳能微型逆变器能够协助太阳能光伏 (PV) 系统实现每个电池板级别的最大功率点跟踪 (MPPT),以提高功率产额, 即使在阴天、树荫、PV 面板上有鸟粪和灰尘等不理想条件下,

Design of Auxiliary Power Supply for the Solar PV Inverter

Jan 1, 2012 · In order to design PV inverter auxiliary power supply, circuit with isolated single-ended anti-flyback current-control mode,is obtained by experimental design of the circuit for

Infineon Solar Power Solutions

Jan 30, 2018 · System cost down: Inverters manufacturers will continuously optimize $/w on system level. System efficiency: Efficiency is key for return of investment. Reliability: 5+years

Photovoltaic Micro Solar Inverter Auxiliary Power Solution

Feb 25, 2025 · The auxiliary power supply of photovoltaic micro solar inverter obtains power from photovoltaic panels. Because the voltage range of photovoltaic panels is very wide (9V-55V),

Auxiliary Power Supply Design Based on LMR38020 Fly

Aug 31, 2023 · This article presents a new auxiliary power supply design for micro inverter based on LMR38020 Fly-BuckTM, with advantages of ease of design, low counts of components in

What are the photovoltaic auxiliary material inverters

Photovoltaic systems are continually evolving to improve their efficiency and financial viability. One trend is to move to larger strings of cells giving higher dc voltages to be converted to ac

A novel wide input range transformerless PV microinverter

4 days ago · Paul, A. R., Bhattacharya, A. & Chatterjee, K. Boost/Buck-boost Based Grid Connected Solar PV Micro-inverter with Reduced Number of Switches and Having Power

A photovoltaic inverter auxiliary power supply circuit system

Jan 17, 2025 · The PV micro-auxiliary source is designed for extremely small power capacity, and the high-voltage auxiliary power supply circuit is designed for small power capacity.

Photovoltaic inverter printed circuit design

The inverter state machine then sequences to checking for DC voltage. To feed current into the grid the DC voltage (which in case of PV inverters is provided from the panel or panel plus

6 FAQs about [Micro photovoltaic inverter auxiliary power supply]

What is micro inverter & auxiliary power supply?

Usually installed under the PV panel, micro inverter is required to have high power conversion efficiency, good thermal performance, small size and long lifetime. The conventional auxiliary power supply is usually a Flyback, either secondary side regulated (SSR) or primary side regulated (PSR).

How much auxiliary power does a micro inverter need?

The recommended maximum load current capability is 2 A, which is also enough for the auxiliary power of micro inverter which usually does not exceed 10 W power need. The Fly-BuckTM is also known as the isolated buck converter, where the isolated output is generated by adding a coupled winding to the filter inductor of a buck converter.

What is auxiliary bias in a micro inverter?

This requires the auxiliary bias supply, which takes power from the PV panel, to be able to produce both the non-isolated low voltage bias voltages for the DSP and signal acquisition circuit, and the isolate bias voltages for the inverter gate drivers' use. Figure 1-4 shows a typical power tree of micro inverter. Figure 1-4.

What is solar micro inverter?

Solar Micro Inverter is able to help the solar photovoltaic PV system to achieve per-panel level Maximum Power Point Tracking (MPPT) to improve power yield performance even in unideal conditions such as cloud or tree shades or bird drops and dust on the PV panels.

What is a auxiliary power supply?

It operates efficiently across a wide input voltage range, typically from 250V to 1000V, accommodating DC link voltage variations. To enhance the overall reliability of your power converter system, our auxiliary power supply features a simple topology and a low component count, ensuring robust performance and ease of integration. Features

How to connect Ti Micro solar inverter to AC source?

Use the AC output line to connect the output terminal J2 of the TI’s micro solar inverter reference design board with the AC Source. The pin definition of J2 is as the following: Connect the AC Source with the resistive load. Table 1.

Learn More

- Kyiv Photovoltaic Power Inverter Supply

- Chile photovoltaic energy storage 15kw inverter power supply

- Photovoltaic inverter power supply

- Can the UPS inverter be connected to the power supply to charge the battery

- Is there an inverter in the DC power supply

- Telecommunication power supply photovoltaic energy storage cabinet solar energy price

- Outdoor Photovoltaic Power Inverter

- Uninterruptible power supply using photovoltaic power generation

- Photovoltaic power supply energy storage new energy vehicle

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.