High Voltage Circuit Breakers: Global Market Trends,

May 6, 2025 · High voltage circuit breakers are at the heart of the global energy transition. While challenges like SF6 phase-outs and ultra-high voltage demands persist, innovations in AI,

Vacuum Switching Technology for Future of Power Systems

Jun 1, 2022 · The technology was confined to low-voltage and low-current but high-frequency interruption applications before the 1920s, when the first vacuum switch was developed. The

Development of High-Voltage Vacuum Circuit Breakers in China

Mar 26, 2025 · XXIInd Int. Symp. on Discharges and Electrical Insulation in Vacuum-Matsue-2006 Development of High Voltage Vacuum Circuit Breakers in China Jimei Wang'', Zhiyuan Liu'',

Live Tank Circuit Breakers

Jul 25, 2025 · Technology XD|GE 252kV and below SF6 high-voltage circuit breakers are designed with a single interrupter (per pole), without parallel or grading capacitors. 363-550kV

未来电力系统真空开关技术

<p>真空开关技术的发展尽管已有一百余年历史,然而近年来新技术的出现对未来输配电系统发展具有显著影响。首先,对于《京都议定书》认定的最强温室效应气体——SF6,

Asia-Pacific High Voltage Circuit Breaker Market by

This report focuses on the High Voltage Circuit Breaker in Asia-Pacific market, especially in China, Japan, Korea, Taiwan, Southeast Asia, India and Australia. This report categorizes the

Top 10 High-Voltage Circuit Breaker Brand & Manufacturers

Jul 22, 2025 · High-Voltage and High-Current Handling: These circuit breakers are designed to handle high-voltage and high-current levels. They have the capacity to interrupt currents

History of vacuum circuit breaker and recent development in Japan

Related papers Development of High-Voltage Vacuum Circuit Breakers in China Shun Yuan IEEE Transactions on Plasma Science, 2007 This paper introduces a research work on the

Development of high-voltage vacuum circuit breakers in China

Aug 4, 2025 · Mitsuru Tsukima; Toshie Takeuchi; Kenichi Koyama; Hajimu Yoshiyasu 2008: Development of a high-speed electromagnetic repulsion mechanism for high-voltage vacuum

Brief History of the Past and Present of High voltage Vacuum

Dec 5, 2024 · Brief History of the Past and Present of High voltage Vacuum Circuit Breakers. Systematically learning this knowledge can help you work better in 2025.

Hydraulic operating mechanisms for high voltage circuit breakers

Dec 30, 2010 · High voltage circuit breakers are the most important protection and control apparatus in power system. As a core part of circuit breakers, the operating mechanisms have

Understanding Voltage and Plug Types in Japan: Essential

Dec 6, 2024 · Voltage converters are equally essential if you plan to use high-powered appliances that are not compatible with Japan''s voltage. Be sure to check your device specifications

Development of High-Voltage Vacuum Circuit Breakers in China

Abstract:Ultra-high voltage fast vacuum circuit breakers (FVCBs) could benefit a power system by promoting transient stability because their opening and closing times are significantly lower

World High voltage breaker imports from China

May 14, 2023 · Create profitable strategy to import High voltage breaker from China with Top High voltage breaker exporting importing countries, Top High voltage breaker importers & exporters

japan circuit breaker price

The japan circuit breaker price is a standout piece in our Circuit Breaker collection.To locate a reliable supplier in China, utilize industry websites, attend trade exhibitions, and seek referrals

Top 10 Manufacturers Shaping the Future of Circuit Breakers

Feb 3, 2025 · Explore the top 10 manufacturers shaping the future of circuit breakers with cutting-edge technology, safety, and efficiency in power systems.

Top 10 Circuit Breaker Manufacturers | CNC Electric

Circuit breakers are the unsung heroes of modern infrastructure, silently protecting homes, factories, and cities from electrical hazards. While giants like Siemens and Schneider Electric

Vacuum Switching Technology for Future of Power Systems

This can thus greatly enhance the transient stability of power networks in the presence of short-circuit faults, especially for ultra- and extra-high-voltage power transmission lines. Third, based

Circuit breakers

2 days ago · Modular design All Siemens Energy high-voltage circuit breakers are designed in a well proven modular platform concept. This leads to a wide variety of breaker types and strong

250_100461_E_T_HP_E_Sonderheft_US dd

Further developments of high voltage transmission systems Figure 1: High voltage test of an Figure 2: 800 kV live tank 800 kV pole for dc voltage circuit breaker To supply electric energy

Brief History of the Past and Present of High

Jul 28, 2022 · A large majority of the respondents wish to start a pilot project with a high voltage vacuum circuit breaker in their system in order to gain

6 FAQs about [High voltage breaker in China in Japan]

Who is the largest circuit breaker manufacturer in China?

As a largest Circuit Breaker manufacturers in china, Korlen electrical produces Circuit Breaker more than 3 million monthly.

Does Hitachi energy offer high-voltage switchgear and breaker solutions?

Ups! something went wrong. Hitachi Energy offers a comprehensive range of high-voltage switchgear and breaker solutions up to 1200 kilovolts AC and 1100 kilovolts DC.

Will Hitachi energy install Italy's first 420 kilovolt sf6-free circuit breaker?

Hitachi Energy will collaborate with Tirreno Power to install Italy’s first eco-efficient 420-kilovolt (kV) SF₆-free circuit-breaker. Manufactured in Italy, the groundbreaking equipment made at Hitachi Energy’s factory in Lodi is set to be installed in 2025.

What is econiq breaker technology?

For Hitachi Energy, this is the very first frame agreement globally for its EconiQ eco-efficient breaker technology. Hitachi Energy today announces it will deliver the world's first sulfur hexafluoride (SF₆)-free 550 kV gas-insulated switchgear (GIS) to the Central China Branch of the State Grid Corporation of China (SGCC).

What is the econiq dead Tank breaker?

On June 20, the breakthrough EconiQ dead tank breaker was delivered to Eversource during an exclusive event at Hitachi Energy’s state-of-the-art factory in Mount Pleasant, Pennsylvania, USA. The agreement affirms the need to reduce F-gas emissions and ensures at the same time that high-voltage substations will remain safe, reliable, and compact.

What is econiq live Tank breaker – LTA?

EconiQ Live Tank Breaker – LTA for 145-kilovolt (kV) to be installed at Heinola substation in Finland will help to do just that. The innovation called EconiQ ™ retrofill uses eco-efficient gas mixture to support National Grid in achieving their sustainability targets.

Learn More

- High voltage breaker in China in Bolivia

- High quality high voltage breaker in China Factory

- High voltage breaker in China in Moldova

- China high voltage breaker in China Price

- High voltage breaker in China in Norway

- Hot sale high voltage breaker in China supplier

- High voltage breaker in China in Chile

- High quality China high voltage switchgear distributor

- High quality double throw breaker in China company

Industrial & Commercial Energy Storage Market Growth

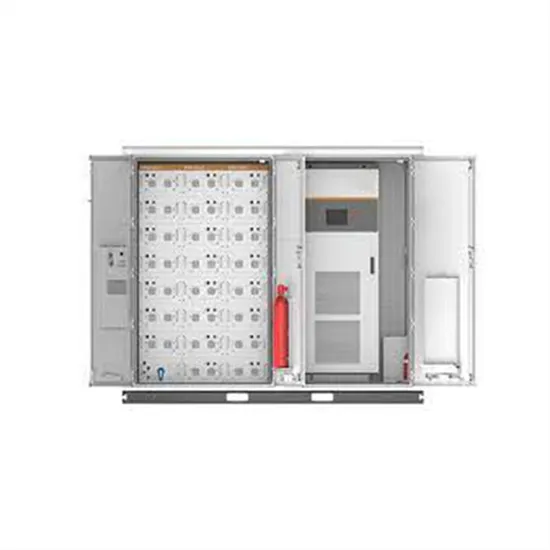

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

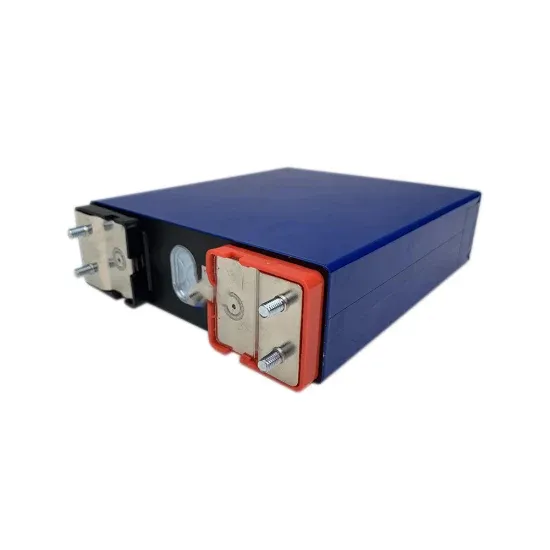

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.