Shanghai Donghai Bridge Offshore wind farm

Feb 9, 2025 · Shanghai Donghai Bridge Offshore wind farm is an operating wind farm in Nanhui District, Pudong Xing District, Shanghai, China. The map below shows the locations of the

Installation and construction process of offshore wind power

Oct 15, 2024 · Title: Installation and construction process of offshore wind power booster station Additional title: 一种海上风电升压站的安装施工工艺 Contributors: QIU WENYONG ( author ) /

How Much Concrete In The Base Of A Wind Turbine?

Jun 29, 2025 · The vast concrete foundations that keep wind turbine towers erect are hidden from view below ground, with poured-in-place foundations being 10-20 feet thick and 60 feet in

Selection, Design and Construction of Offshore Wind

Sep 25, 2018 · In the United States, offshore wind power development has not been a focus area because there is great potential for wind power on land. However, high quality onshore wind

Construction of Offshore Wind Turbine Foundation Structure

Apr 15, 2025 · The intricate and ever-changing environment, geological conditions, wind turbine capacities, and resources for construction and installation at offshore wind farms necessitate a

Analysis of Cooling Systems for Offshore Wind Power

Jun 27, 2024 · Yingjie Zhao, Tong Xu, Guozeng Feng, and Ngabonziza Caleb Kazora Abstract In this study, three types of cooling systems—varied refrigerant volume (VRV) cooling system,

Review of integrated installation technologies for offshore wind

Mar 1, 2022 · The large-diameter internal-cabin suction bucket foundation and integrated installation technology have been successfully applied to a number of offshore wind farms,

Construction Procedures and Standards of Cellular

Feb 15, 2019 · Define high level technical criteria for the construction of sharable Cellular Mobile Base Stations and Towers, Sites and associated infrastructure in the State of Qatar; Health

Overview of the development of offshore wind power

Oct 1, 2022 · In 2019, there were 23 offshore wind power projects under construction around the world with a total capacity of 7 GW, 13 of which were in China, making it the second largest

DESIGN AND SIMULATION OF WIND TURBINE ENERGY

Dec 30, 2023 · Abstract- The increasing demand for wireless communication services in rural areas has necessitated the installation of more base stations. The challenge in these regions

Step-by-Step Guide to Wind Turbine Installation

Nov 2, 2024 · Discover wind turbine installation steps, from site assessment to grid connection, and boost your energy game! Wind energy is an essential part of the move toward sustainable

Development of offshore wind power and foundation

Dec 15, 2022 · This paper reviews the development of offshore wind power and foundation technology used for offshore wind turbines in China using published data and web sources. An

An overview of the policies and models of integrated

Jun 1, 2023 · The offshore base station can not only effectively guarantee the construction and operation of offshore wind power, but also provide mobile communication services for the

Offshore Wind: Design, Development, Construction,

Sep 20, 2024 · Offshore wind is now viewed as a mainstream generation source that can be scaled and deployed globally. Most of the recent offshore wind farms being designed and

China promotes construction of large-scale wind

Jun 15, 2023 · Of all the countries, China will consolidate its leading position, accounting for 55 percent of global additions of renewable power capacity in

Construction of pumped storage power stations among

Jan 1, 2025 · Next, based on different utilization principles of wind power and photovoltaic, the multi-energy complementary operation models of the hydropower-wind-PV hybrid system, the

Design & Construction Considerations for Offshore

Oct 14, 2024 · Design & Construction Considerations for Offshore Wind Turbine Foundations in North America noise impacts to local communities. But developing these wind resources 15 to

6 FAQs about [Base station wind power source installation and construction]

How are offshore wind turbine foundations installed?

The installation methods for offshore wind turbine foundations are summarized. The integrated installation technology based on bucket foundation is introduced. Challenges and future trends in deep-ocean wind farm development are discussed.

How important are offshore wind power foundations?

Considering that the construction and installation cost of an offshore wind power foundation account for 35%–55% of the development cost of an offshore wind farm, the innovation in foundation forms and their installation technologies is of great significance.

How do offshore wind farms work?

Offshore wind farms are a key component in the transition to renewable energy, harnessing the power of wind over the sea to generate electricity. The construction of these massive installations involves several phases, each requiring careful planning and advanced technology. Here’s an overview of the construction process based on industry insights.

What is the level of offshore wind power Foundation after installation?

The level of offshore wind power foundation after installation is a key indicator for construction quality control. According to the DNV specification, it is required that after the completion, the cumulative total inclination angle of the foundation mud surface during the entire operation period should not exceed 0.50° .

Where should a wind turbine nacelle be installed?

When the installation is performed offshore, the nacelle should be installed on the top of the tower first, and then the assembled wind turbine head should be directly hoisted onto the nacelle, thereby reducing the difficulty in offshore construction.

What is the construction phase of an offshore wind farm?

The construction phase is typically the most challenging and time-consuming part of the offshore wind farm development process. It involves: Installing the foundations for the wind turbines, which are typically large steel structures that are anchored to the seabed.

Learn More

- Base station wind power source all

- Abu Dhabi communication base station wind power construction standards

- How much electricity does the base station wind power source consume

- Reykjavik communication base station wind and solar hybrid power generation installation

- Uzbekistan 5g communication base station wind power construction project

- How to build a wind power communication base station

- Construction of inverter grid-connected power supply for China-Africa communication base station

- American communication wind power base station manufacturer

- Terminal communication base station wind power

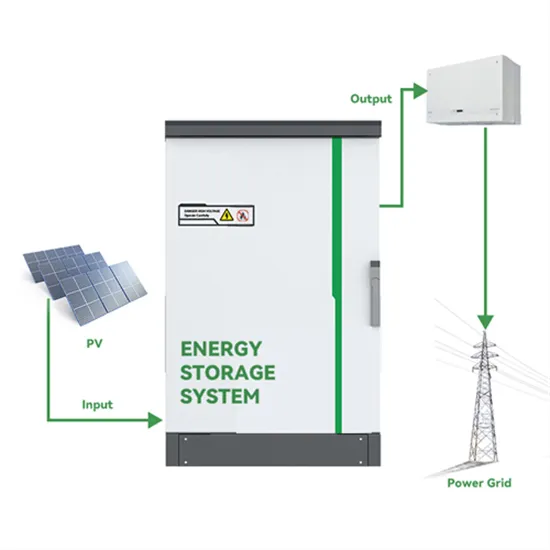

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.