Big 5 Construct Ethiopia spotlights opportunities

Jun 7, 2025 · Ethiopia''s construction market is valued at $67 billion, driven by the country''s economic growth priorities under its Ten-Year Development Plan

Managing and Minimizing Wastage of Construction Materials

Therefore, this research were attempt to assess the current situation of managing and minimizing wastage of construction materials in the Addis Ababa on selected public building construction

Concrete energy storage Ethiopia

field of construction materials. Energy-harvesting concrete has the capability to store or convert the ambient energy (e.g., light, thermal, and mechanical energy) for feasible uses, alleviatin

Business building energy storage ethiopia

This study focuses on the solar PV energy system in rural Ethiopia in conjunction with a battery and a DG for energy storage and backup power supply, respectively and also examines how

Construction Quality & Technology Center of Excellence

The Construction Quality and Technology Center of Excellence (CQT CoE) is among the identified centers of excellence designated by the ministry of science and technology for

Ethiopia Restarts Scheme to Build Tallest Tower in Sub

Jun 12, 2025 · Ethiopia has resumed a project to construct a $445 million, 62-storey headquarters for Ethiopian Electric Power (EEP) in Addis Ababa, set to become the tallest building in sub

Feature: Chinese-built cement plant helps Ethiopia advance

Mar 17, 2025 · He said that the entire cement production line, beginning with limestone crushing and long-belt conveying, through raw material and fuel entry, and culminating in finished

Embodied Energy and CO2

May 30, 2019 · The study also recommended several strategies for the reduction of embodied energy and the related CO2emissions. The research delivers critical insights into embodied

FINANCIAL EVALUATION OF ONE FEASIBILITY STUDY

Jan 16, 2025 · In May 1981 Mr. John Clark of Clark Ceramic Consultants and Mr. Richard Whittle of Soil Mechanics Ltd., visited the offices of Ethiopian Building Materials Corporation in Addis

New energy storage project signed in ethiopia

Ethiopia has signed purchase and implementation agreements for the 300 MW Aysha-1 wind farm with AMEA Power of the United Arab Emirates (UAE).The Aysha wind energy project is set to

ST. MARY''S UNIVERSITY SCHOOL OF GRADUATE STUDIES

Oct 28, 2021 · ENDORSEMENT This is to certify that this project work, "practices of materials management at construction sites in the case of small sized construction enterprise in kolfe

Construction Materials Waste and its Management

Dec 16, 2020 · The Construction industry, while contributing to overall socio-economic development of any country, is a major exploiter of natural non-renewable resources and a

ETHIOPIAN STANDARDS

Mar 13, 2023 · The In nstitute of E Ethiopian Sta andards (IES) is the national standards body of Ethiop pia. IES is re--named by th he proclamatio on number 12 263/2021, fro om Ethiopian

Climate-Responsive Optimization of Phase Change Materials for Energy

Jun 30, 2025 · To evaluate the energy performance of PCM-integrated wall assemblies in Ethiopian buildings, this study employed EnergyPlus, a dynamic simulation engine capable of

The Ethiopian energy sector and its implications for the

Aug 1, 2022 · These and other features reveal that Ethiopia lacks a modern, flexible, reliable, and affordable energy system that could withstand its fast-growing energy demand due to high

Chinese-built cement plant helps Ethiopia advance

Mar 13, 2025 · He said that the entire cement production line, beginning with limestone crushing and long-belt conveying, through raw material and fuel entry, and culminating in finished

BUILDEXPO Africa Ethiopia 2025: Addis Ababa Building & Construction

Jul 3, 2024 · BUILDEXPO Africa Ethiopia 2025 is the only show with the widest range of the latest technologies in construction machinery, building material machines, mining machines,

Modern Methods of Construction in Addis Ababa Buildings

Aug 17, 2024 · On a study of condominium housing projects in Addis Ababa Dires (2016) stated that the rate of construction project completion is weak because of the fast increasing rate of

St. MARY''S UNIVERSI

Oct 28, 2021 · According to Andualem (2019), construction material management is an essential role in construction projects that contributes significantly to the project''s success. Ineffective

3 FAQs about [Ethiopia building materials energy storage project]

Why is construction industry important in Ethiopia?

Ethiopian government has identified construction industry as one of the three sectors of the economy to accelerate the country's economic development. Usually, conventional building materials such as iron, cement and concrete are not produced in sustainable ways.

Are building materials sustainable?

Usually, conventional building materials such as iron, cement and concrete are not produced in sustainable ways. The production and transport of such materials lead to relatively high levels of greenhouse gas emission. Alternatively, there are also locally produced and used building materials that do not cause substantial CO2 emissions.

Are alternative building materials sustainable?

Some of the Alternative Building Materials that are sustainable in nature according to includes: straw bale, bamboo, manufactured sand, ferrock and C&D waste to mention but a few. There is therefore, the need to understand the sustainable construction aspect of these materials.

Learn More

- Indonesia office building energy storage project

- Kuwait Photovoltaic Energy Storage Project

- How much electricity does an energy storage project usually generate

- Tajikistan Independent Energy Storage Project

- Baghdad Energy Storage Photovoltaic Project

- What is the electric energy storage project

- 240w energy storage project

- 2000 kW energy storage project

- Photovoltaic supporting energy storage project

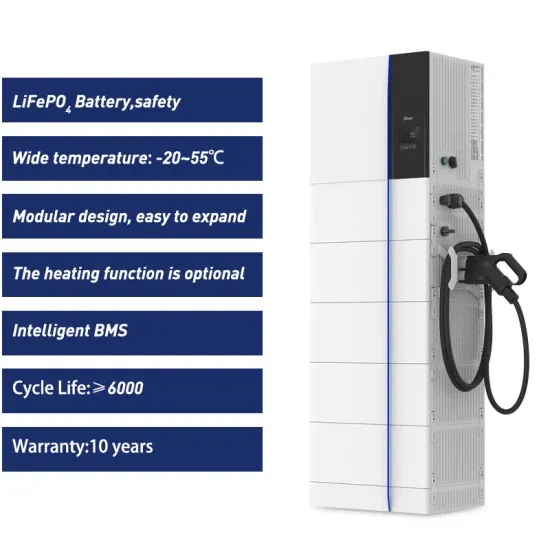

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.