Battery storage systems

Feb 10, 2024 · • Long life open-vented lead batteries with flame-retardant containers. • Long life nickel-cadmium (NiCd) batteries for special applications. • Lithium-ion (Li-ion) batteries with

Nickel-cadmium battery energy storage container sales

Nickel-cadmium battery energy storage container sales How Nickel-Cadmium Batteries Work. Early Ni-Cd cells used pocket-plate technology, a design that is still in production today.

NICKLE CADMIUM (NiCd) BATTERY FOR POWER

Apr 11, 2022 · Sauer et al. (2007). Detailed cost calculations for stationary battery storage systems. Second International Renewable Energy Storage Conference (IRES II) Bonn, 19.

Nickel-cadmium battery energy storage container price

About Nickel-cadmium battery energy storage container price The 2024 ATB represents cost and performance for battery storage with durations of 2, 4, 6, 8, and 10 hours. It represents lithium

NICKEL CADMIUM BATTERY ENERGY STORAGE CONTAINER

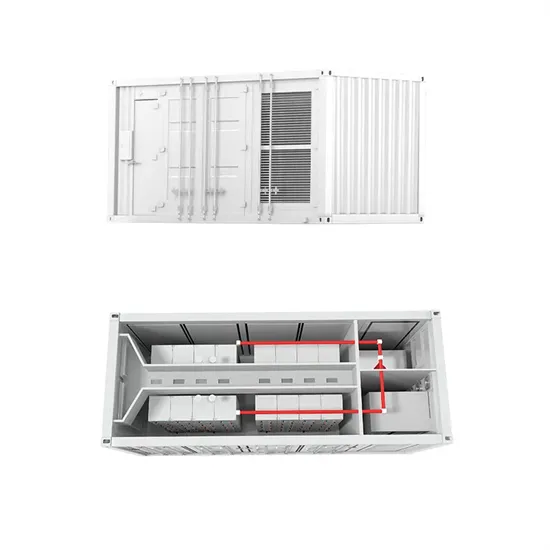

Energy storage container battery system principle A battery energy storage system (BESS), battery storage power station, battery energy grid storage (BEGS) or battery grid storage is a

Ni-Cd Block battery range

Sustainable, reliable, and robust batteries for back-up power Stationary batteries are used in refineries, power plants, onshore & offshore oil & gas industries, substations, airports &

nickel-cadmium battery energy storage container

Since the invention of nickel–cadmium (Ni-Cd) battery technology more than a century ago, alkaline batteries have made their way into a variety of consumer and professional

Installation of nimh battery energy storage containers in

Nickel-cadmium batteries for energy storage applications | IEEE . Battery energy storage (BES) is a catchall term describing an emerging market that uses batteries to support the electric power

Best Practices for Storing Ni-Cd Batteries – Leading Battery

Feb 8, 2025 · Proper storage of nickel-cadmium (Ni-Cd) batteries is essential to preserve their performance and longevity. Follow these best practices to ensure optimal storage conditions:

Battery Storage Tips: Battery Chemistries and the

Jul 14, 2022 · Nickel-metal hydride has basically the same storage requirements as nickel-cadmium chemistries. They may be stored in charged or discharged

seoul nickel-cadmium battery energy storage container

Battery Energy Storage Systems (BESS) containers are revolutionizing how we store and manage energy from renewable sources such as solar and wind power. Known for their modularity and

Nickel–Cadmium and Nickel–Metal Hydride Battery Energy Storage

Jan 1, 2015 · Whereas sodium–sulfur technology is most common for utility scale energy storage (with some 300 MW of storage capacity installed worldwide, 50% thereof in Japan) providing a

How to store nickel based batteries – BatteryGuy

May 3, 2024 · Nickel based batteries are more flexible than many other battery types. The ideal storage temperature is 50°F (10°C). The minimum storage temperature is -4°F (-20°C). The

Huijue nickel-cadmium battery energy storage container

Nickel-cadmium batteries for energy storage applications Battery energy storage (BES) is a catchall term describing an emerging market that uses batteries to support the electric power

Nickel Cadmium Battery: Overview, Uses, Pros, Cons, And

Dec 19, 2024 · A nickel-cadmium (NiCd) battery is a rechargeable battery that uses nickel oxide hydroxide and metallic cadmium as electrodes. NiCd batteries offer advantages like high

FNC NiCd_8pp_engl.qxd

Mar 1, 2019 · Fiber Nickel Cadmium (FNC®) technology provides the best solution for long reliable battery life in all applications. The electrochemical advantages of the FNC® Nickel

thailand nickel-cadmium battery energy storage container

By interacting with our online customer service, you''ll gain a deep understanding of the various thailand nickel-cadmium battery energy storage container featured in our extensive catalog,

Brazilian nickel-cadmium battery energy storage container

What is Brazil''s largest battery storage project? Further details about Brazil''s largest battery storage project to date have been revealed including its integrators and equipment providers.

Nickel – Cadmium Batteries

Jun 3, 2020 · The electrical connector typically is mounted on the front of the battery container; but on some battery types the electrical connector is mounted at the side. It enables electrical

6 FAQs about [Nickel-cadmium battery energy storage container]

How do you store a nickel cadmium battery?

Nickel Cadmium batteries can be stored in similar conditions as Nickel Metal Hydride batteries. The ideal storage temperature is 50°F (10°C), with a minimum of -4°F (-20°C) and a maximum of 113°F (45°C).

What is the maximum storage temperature for nickel based batteries?

The ideal storage temperature is 50°F (10°C). The minimum storage temperature is -4°F (-20°C). The maximum storage temperature is 113°F (45°C). Both Nickel Cadmium batteries and Nickel Metal Hydride batteries can be stored in similar conditions.

What is nickel based energy storage - Pibas batteries?

Nickel-based Energy Storage - PIBAS Batteries. We store energy. PIBAS ® Ni-Cd ranges ranges build on the well proven pocket plate design combined with new latest technology components are leading the battery world in terms of high performance, longest proven service life, widest operational temperature range and lowest maintenance requirments.

What temperature should a nickel cadmium battery be stored at?

Nickel Cadmium batteries should be stored at 50°F (10°C). While 32°F (0°C) is not recommended as it may freeze and cause damage, 50°F (10°C) is a suitable compromise to avoid both freezing and rapid discharge in storage.

What is the shelf life of a Nickel Cadmium battery?

Under the right conditions, a Nickel Cadmium battery can have a shelf life of between 2 to 3 yrs. The following guidance is based on batteries that are kept at the right temperature, the right humidity and in the correct State of Charge.

What chemistry does a nickel cadmium battery use?

Electrochemistry of nickel-cadmium batteries The nickel-cadmium battery uses nickel hydroxide as the active material for the positive plate, and cadmium hydroxide for the negative plate.

Learn More

- Burkina Faso s new energy storage battery container

- Lithium battery cost for container energy storage system

- Analysis of energy storage battery container usage base station

- Vienna Communication Base Station Energy Storage Battery Container

- What is the capacity of the container photovoltaic energy storage battery warehouse

- Ngerulmud container energy storage lithium battery enterprise

- Korea s container energy storage lithium battery solution

- How many tons does a 4mwh energy storage battery container weigh

- Container energy storage battery real

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.