Grid-connected photovoltaic inverters: Grid codes,

Jan 1, 2024 · The proliferation of solar power plants has begun to have an impact on utility grid operation, stability, and security. As a result, several governments have developed additional

Modeling and Control Parameters Design for Grid-Connected Inverter

Nov 5, 2019 · Small-signal stability problems often occur when the inverter for renewable energy generation is connected to weak grid. A small-signal transfer function integr

Modeling and Control Parameters Design for Grid-Connected Inverter

Nov 5, 2019 · Small-signal stability problems often occur when the inverter for renewable energy generation is connected to weak grid. A small-signal transfer function integrated model

Grid-Forming Inverters – Enabling the Next Generation

May 15, 2023 · Grid-Forming Inverters Inverter-base resources Grid-forming inverter control Regulate terminal voltage Islanded operation, maintain grid stability, black start, etc. Types of

Small-signal modelling and stability analysis of grid

Jun 1, 2023 · In this paper, the explicit state-space model for a multi-inverter system including grid-following inverter-based generators (IBGs) and grid-forming IBGs is developed by the two

Grid-Connected Solar Microinverter Reference Design

Nov 29, 2011 · There are two main requirements for solar inverter systems: harvest available energy from the PV panel and inject a sinusoidal current into the grid in phase with the grid

What Is Base Station in Mobile Communication? – The Heart

Jan 11, 2025 · In the era of rapid technological advancements, mobile communication has become an integral part of our daily lives. With the increasing demand for high-speed data and

P/Q Control of Grid-Connected Inverters

Mar 25, 2021 · In photovoltaic grid-connected (GC) and DG systems, one of the objectives that the grid-connected inverters (GCI) is the control of current coming from the photovoltaic

Grid Connected PV System Connects PV Panels to the Grid

Jun 21, 2024 · Inverter – The inverter is the most important part of any grid connected system. The inverter extracts as much DC (direct current) electricity as possible from the PV array and

Control strategy for current limitation and maximum capacity

May 2, 2024 · Under grid voltage sags, over current protection and exploiting the maximum capacity of the inverter are the two main goals of grid-connected PV inverters.

GRID CONNECTED PV SYSTEMS WITH BATTERY ENERGY

May 22, 2023 · The term battery system replaces the term battery to allow for the fact that the battery system could include the energy storage plus other associated components. For

How Solar Energy Systems are Revolutionizing Communication Base

Nov 17, 2024 · Why Solar Energy for Communication Base Stations? Being a clean and renewable energy source, solar energy emits much less greenhouse gas compared to the

Wireless & Fixed Telephone Networks Questions & Answers

3 days ago · Answer: b Explanation: To provide wireless communication within a particular geographic region, an integrated network of base stations must be deployed to provide

Control design of grid-connected three-phase

Aug 6, 2024 · A brief overview of various inverter topologies along with a detailed study of the control architecture of grid-connected inverters is presented. An

SOLAR ENERGY GRID INTEGRATION SYSTEMS

Jul 15, 2025 · When using GPRS/4G communication mode, each inverter needs to be equipped with a data collector with GPRS/4G communication module, built-in SIM card or use an

Design and Analysis of Single Phase Grid Connected

Apr 27, 2024 · Fig.2. shows the equivalent circuit of a single-phase full bridge inverter with connected to grid. When pv array provides small amount DC power and it fed to the step-up

Grid Connected Inverter Reference Design (Rev. D)

May 11, 2022 · Grid Connected Inverter Reference Design Description This reference design implements single-phase inverter (DC/AC) control using a C2000TM microcontroller (MCU).

Modeling simulation and inverter control strategy research

Nov 1, 2022 · A standard microgrid power generation model and an inverter control model suitable for grid-connected and off-grid microgrids are built, and the voltage and frequency fluctuations

CSEE JOURNAL OF POWER AND ENERGY SYSTEMS, VOL.

Abstract—For a multi-inverter grid-connected system, the sta-bility of the point of common coupling (PCC) voltage is evaluated considering the distribution parameters of the

6 FAQs about [A small communication base station inverter in Georgia is connected to the grid]

What is the control design of a grid connected inverter?

The control design of this type of inverter may be challenging as several algorithms are required to run the inverter. This reference design uses the C2000 microcontroller (MCU) family of devices to implement control of a grid connected inverter with output current control.

How does a PV inverter state machine work?

The inverter state machine then sequences to checking for DC voltage. To feed current into the grid the DC voltage (which in case of PV inverters is provided from the panel or panel plus some conditioning circuit), it must be greater than the peak of the AC voltage connected at the output of the inverter.

What is a grid connected PV system?

Grid connected PV systems always have a connection to the public electricity grid via a suitable inverter because a photovoltaic panel or array (multiple PV panels) only deliver DC power. As well as the solar panels, the additional components that make up a grid connected PV system compared to a stand alone PV system are:

What is a grid-connected solar microinverter system?

A high-level block diagram of a grid-connected solar microinverter system is shown in Figure 4. The term, “microinverter”, refers to a solar PV system comprised of a single low-power inverter module for each PV panel.

Can a PV system serve a load without a grid?

The PV system has no storage and cannot serve the load in the absence of the grid. The PV system produces power at unity power factor and utility supplies all Volt Ampere reactive power. The inverter meets the requirements of IEEE 1547-2005. There is no direct communication or control between the utility and the inverter.

How do inverter/controllers work?

The inverter/controllers will interact with building energy management systems and/or smart loads, with energy storage, and with the electric utility to allow the integration of relatively large amounts of PV energy while maintaining or increasing grid reliability.

Learn More

- Communication base station inverter connected to the grid outdoors

- The inverter for Moldova s communication base station is connected to the grid by Huawei

- Managua communication base station inverter connected to the grid

- Solomon Islands communication base station inverter connected to the grid 6 25MWh

- Which factories are connected to the grid for the inverter of the Pristina communication base station

- Australian outpost communication base station inverter connected to the grid 6 9MWh

- Which manufacturers are connected to the grid for East Asia communication base station inverters

- Outdoor communication base station inverter grid connection

- Does the communication base station inverter need a transformer to connect to the grid

Industrial & Commercial Energy Storage Market Growth

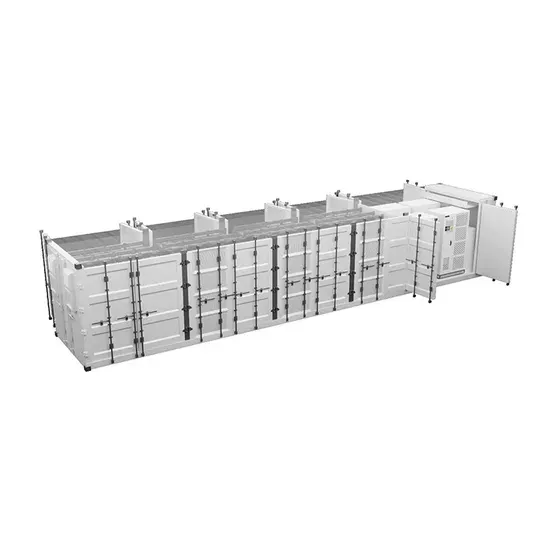

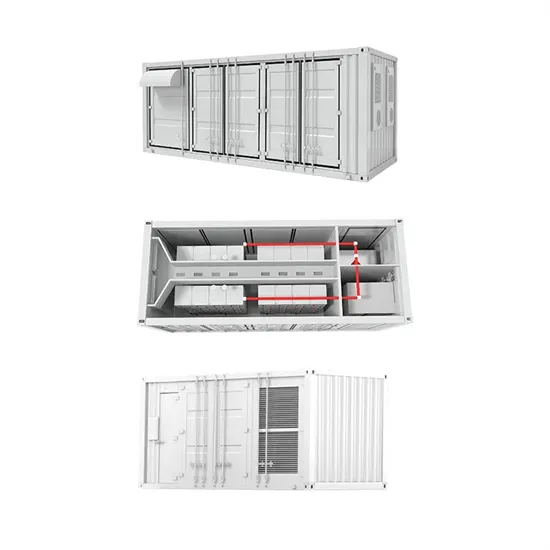

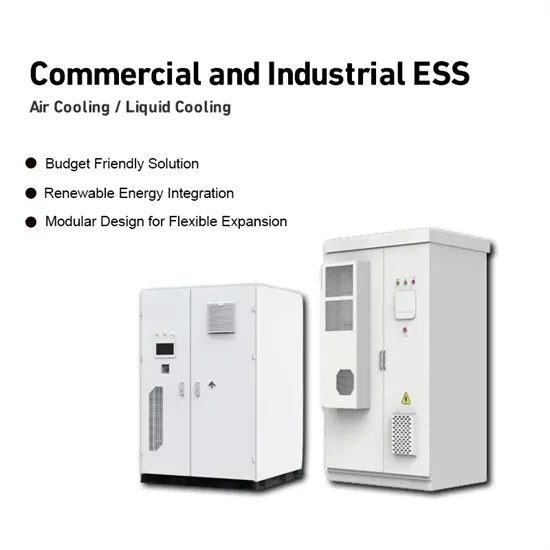

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

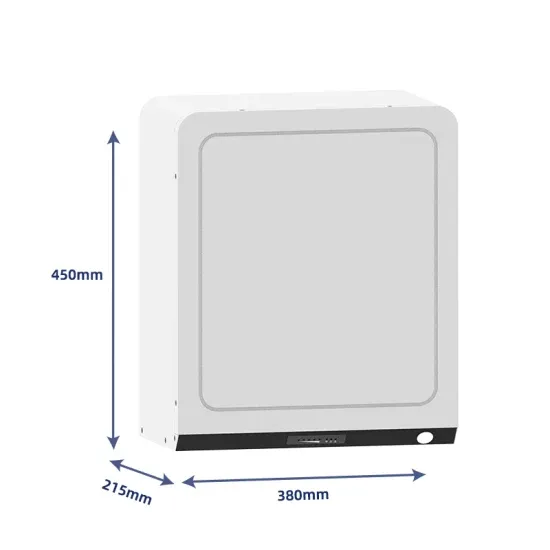

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.