How many watts can a typical solar cell provide?

Jan 26, 2024 · A typical solar cell can provide approximately 250 to 400 watts per panel under optimal conditions, which translates to about 200 to 300 watts of

How many watts does a battery solar panel have

Sep 16, 2024 · To determine the wattage of a battery solar panel, various factors come into play, including the panel''s size, efficiency, and the intensity of

Solar Panel Amps Calculator (Watts to Amps) –

Mar 3, 2023 · How to use this calculator? Solar panel output: Enter the total capacity of your solar panel (Watts). Vmp: Is the operating voltage of the solar

Solar Panel Wattage Explained: How Many Watts

Jul 1, 2025 · Wattage refers to the amount of electrical power a solar panel can produce under standard test conditions (STC), which simulate a bright sunny

Solar Panel kWh Calculator: kWh Production Per

3 days ago · Solar Output = Wattage × Peak Sun Hours × 0.75 Based on this solar panel output equation, we will explain how you can calculate how many

Standard Solar Panel Sizes And Wattages (100W

2 days ago · Rather, we get the typical sizes of solar panels by the number of cells (which is quite useless). There are 3 standardized sizes of solar panels,

How many watts does a solar cell generate? | NenPower

Aug 1, 2024 · 1. The wattage generated by a solar cell varies based on multiple factors, and it can range from 100 watts to 370 watts or even higher for standard residential panels. 2. Factors

Solar Panel Watts Per Square Foot: ''We (Finally) Did The Math''

2 days ago · Alright, a lot has been said about solar panel watts per square foot. Everybody agrees this is a very important specification. There is a lot of disagreement on how many watts

How many watts does a solar cell produce per

Feb 2, 2024 · To determine how many watts a solar cell produces per hour, several critical aspects need to be considered, including 1. solar cell efficiency,

How many watts does a photovoltaic solar cell have

How many Watts Does a solar panel produce? Cell Count vs Wattage When we discuss output of the solar panel, we usually use it''s wattage. For residential applications, a typical solar panel is

6 FAQs about [How many watts does a solar cell have ]

How many watts are in a solar panel?

This is determined by the type of semiconductor material used and the total number of solar cells in the panel. In the current market, residential solar panels typically contain between 36 and 144 cells, with wattage outputs now ranging from 325 watts to 440 watts.

How many watts can a solar cell make?

Under standard conditions, a cell can make about 0.7 watts. Conditions are 1,000 W/m² sunlight, 25°C, and air mass 1.5. How can the power output of a single solar cell be calculated? To find a cell’s power, you multiply sunlight by cell efficiency. The formula is: Power Output = Solar Irradiance × Solar Cell Efficiency.

What is solar wattage?

Wattage refers to the amount of electrical power a solar panel can produce under standard test conditions (STC), which simulate a bright sunny day with optimal solar irradiance (1,000 W/m²), a cell temperature of 25°C, and clean panels. In simpler terms, a panel’s wattage rating tells you its maximum power output under ideal conditions.

How much power does a 400 watt solar panel produce?

A 400 W solar panel can produce around 1.2-3 kWh or 1,200-3,000 Wh of direct current (DC). The power produced by solar panels can vary depending on the size and number of your solar panels, the efficiency of solar panels, and the climate in your area. How many solar panels are needed to run a house?

How much electricity does a solar panel produce?

The most frequently quoted panels are around 450 watts, so we'll use this as an example. If you live in a sunny state like California, your panel's production ratio is probably around 1.5, meaning a 10 kilowatt (kW) system produces 15,000 kilowatt-hours (kWh) of electricity in a year.

How many solar panels do I Need?

Your panels' actual output will depend on your roof's shading, orientation, and hours of sun exposure. The efficiency and number of cells in your solar panels drive its power output. You'll need between 16 and 25 solar panels to cover your home's electricity usage. Note: These costs are based on EnergySage Marketplace data.

Learn More

- How many watts does a solar cell have

- How many watts are there in a 10gw solar cell

- How many watts of solar energy are installed in a C-type RV

- How long can a solar cell cabinet be used outdoors

- How many watts do solar panels usually have

- How many watts are solar water pumps

- How many watts does 5v solar actually have

- How many watts does solar energy directly invert

- How much does 60 watts of home solar power cost

Industrial & Commercial Energy Storage Market Growth

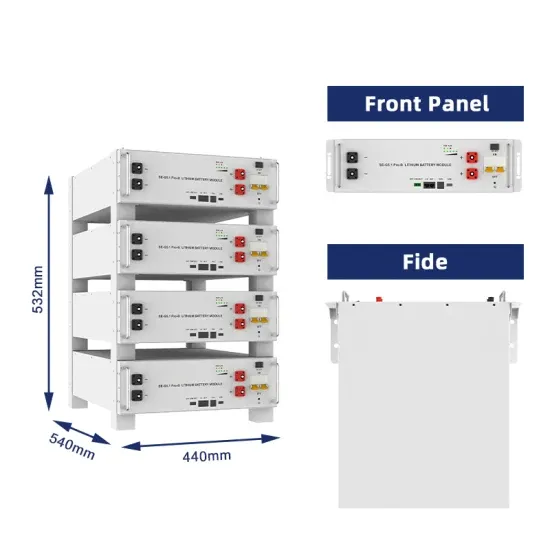

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.