Solar Energy Collection Systems | SpringerLink

Jun 14, 2024 · There are three types of the non-concentrating type of collectors, such as flat plate collectors, evacuated tube collectors and compound parabolic collectors. Table 3.1 shows the

Solar Flat Plate Collector Analysis

Mar 5, 2012 · Flat plate collectors easily attain temperatures of 40 to 70oC. With very careful engineering using special surfaces, reflectors to increase the incident radiation, and heat

Evaluation of a Solar Flat Plate Collector''s

Aug 15, 2025 · The performance parameters, including Nusselt number and collector efficiency, were examined at different mass flow rates of the working fluid. The assessment of flat plate

Comparative performance analysis of flat plate solar collector

Aug 15, 2022 · Flat plate Solar collectors are in use for a long time and have well-established technologies for low-temperature thermal applications. Use of newglaz

Thermal performance enhancement of a flat plate solar collector

Jul 1, 2020 · One practical and effective way of enhancing the efficiency of solar collectors is by employing high thermal and conductive working fluids (Alipour et al., 2017; Esen and Esen,

Feasibility Study of Theoretical Efficiency Calculation for Flat Plate

Sep 25, 2023 · Among its crucial utilization methods, solar water heating systems integrating flat plate collectors (FPCs) emerge as vital contributors in harnessing and converting solar energy

Flat-Plate Collectors

Apr 11, 2017 · The simplest flat plate collectors are the solar ponds and the solar stills which operate by direct utilization of the incident solar radiation acting simultaneously as solar

CHAPTER FOUR Solar Thermal Energy Collectors

Oct 28, 2018 · 4.2 FLAT PLATE COLLECTOR Flat-plate solar collector: It has no optical concentrator. Here, the collector area and the absorber area are numerically the same, the

IJRAR Research Journal

Nov 1, 2023 · Abstract solar flat plate collector is a tool used to gather and transform solar energy into heat for a variety of uses, including industrial processes, water heating, and space

Study the thermal response of a solar flat-plate collector

Jun 1, 2025 · The target of the current study is to investigate and comparing the thermal response of solar flat plate collector (SFPC) for traditional and new model numerically and

Flat-Plate Collectors

Aug 29, 2017 · 7.1 Introduction Solar energy collectors are devices employed to gain useful heat energy from the incident solar radiation. They can be of the concentrating or the flat-plate type.

Energy Engineering dept / 4th class (2015-2016) / design

Sep 28, 2018 · This is defined as the ratio of the useful energy delivered to the energy incident on the collector aperture. The incident solar flux consists of direct and diffuse radiation. While flat

Concentration Ratios for Flat-Plate Solar Collectors with

May 23, 2012 · A comprehensive optimization model for flat solar collector coupled with a flat booster bottom reflector based on an exact finite length simulation model Theoretical and

Flat‐Plate Collectors

Feb 25, 2020 · The collector heat removal factor relates the actual useful energy gain of a collector to the useful gain if the whole collector surface were at the fluid inlet temperature. The

A review of solar air flat plate collector for drying application

Mar 1, 2019 · Various solar collectors are described and classified, and the designs and performance levels of solar collectors with fins integrated to a fluidized bed combination of

(PDF) Analysis of a Flat-plate Solar Collector

In the solar-energy industry great emphasis has been placed on the development of "active" solar energy systems which involve the integration of several subsystems: solar energy collectors,

Feasibility Study of Theoretical Efficiency Calculation for

Bringing new technology to use free and green energy for a poor nation is a benefit, this article compares and evaluates the effectiveness, reliability, and efficiency of flat-plate solar collectors

A comprehensive analysis on advances in application of solar collectors

Sep 15, 2020 · The presented review is focused on synergistic approaches, processes, design criterions and advances in working fluids to achieve optimum thermal and exergy efficiency for

"Performance comparison of innovative spiral shaped solar collector

Mar 1, 2020 · In this work single spiral shaped collector tube as compare to number of riser tubes connected with headers in conventional type flat plate solar collector has been developed.

Experimental comparative analysis of a flat plate solar collector

Aug 1, 2020 · In this work, a comparative experimental analysis of a conventional flat plate solar collector (FPSC) and an identical prototype with thermal storage system by PCM is presented.

RIIODWSODWHVRODUFROOHFWRUSHUIRUPDQFHZLWKWZLVWHG

Mar 15, 2021 · The simple flat plate solar collector consists of a flat plate and the heat pipe sit in this plate that sealed and evacuated pipe lined with an annular porous wicking material and a

Analysis of a Flat-plate Solar Collector

May 14, 2008 · ABSTRACT In the solar-energy industry great emphasis has been placed on the development of "active" solar energy systems which involve the integration of several

A comprehensive analysis on advances in application of solar collectors

Sep 15, 2020 · Flat plate solar collectors are simplest, cost effective and popular solar energy harvesting systems. Progressive advancement in flat plate solar collector has been contributed

6 FAQs about [The ratio of flat-plate solar collector and container]

What is a flat plate solar collector?

1. Introduction: Flat plate solar collectors are simplest, cost effective and popular solar energy harvesting systems. Progressive advancement in flat plate solar collector has been contributed by modification in design, insulation material, process improvement and advanced working fluids (nano-fluids) of vast varieties.

What is the difference between concentrating and flat-plate solar collectors?

This is defined as the ratio of the useful energy delivered to the energy incident on the collector aperture. The incident solar flux consists of direct and diffuse radiation. While flat-plate collectors can collect both, concentrating collectors can utilize direct radiation only if the concentration ratio is greater than (10).

How a flat plate solar collector is progressing?

Progressive advancement in flat plate solar collector has been contributed by modification in design, insulation material, process improvement and advanced working fluids (nano-fluids) of vast varieties. Any change in one parameters may bring about compatible changes in other parameters.

What is the thermal analysis of a solar flat plate collector?

The thermal analysis of a solar flat plate collector is quite complicated because of the many factors involved. Efforts have been made to combine a number of the most important factors into a single equation and thus formulate a mathematical model which will describe the thermal performance of the collector in a computationally efficient manner.

What are the simplest flat plate collectors?

The simplest flat plate collectors are the solar ponds and the solar stills which operate by direct utilization of the incident solar radiation acting simultaneously as solar energy converters. The importance of flat-plate collectors is that their thermal performance can be predicted and treated in considerable detail. 2.

How hot does a flat plate solar collector get?

Flat plate collectors easily attain temperatures of 40 to 70oC. With very careful engineering using special surfaces, reflectors to increase the incident radiation, and heat-resistant materials, higher operating temperatures are feasible. The main components of a flat plate solar collector:

Learn More

- Solar panel installation container site

- Ground digital solar energy storage container

- Container roof foldable solar panel

- Photovoltaic simple container solar energy

- Vaduz outdoor solar photovoltaic folding container liquid cooling

- Outdoor Solar Container Liquid Cooling

- Solar panel container temperature is low

- High-rise solar panel container installation

- Equipment container converted to solar power supply

Industrial & Commercial Energy Storage Market Growth

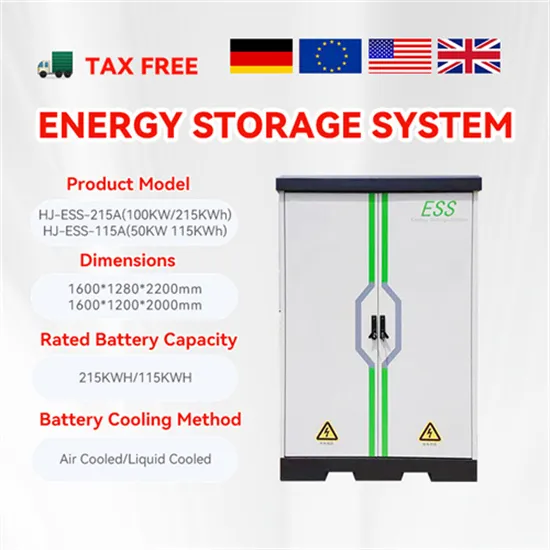

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.