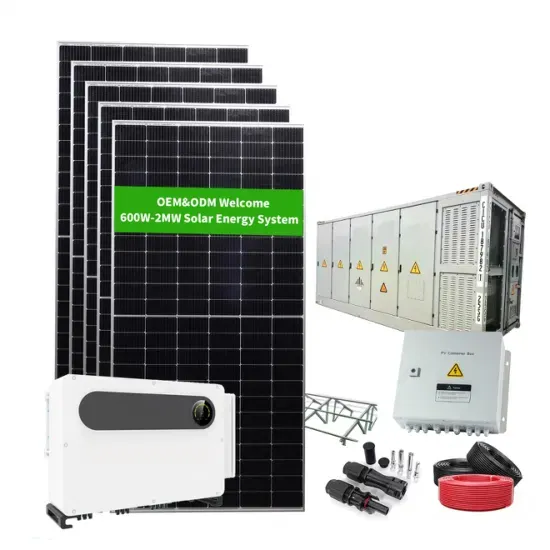

Energy storage power station inverter equipment

Feb 25, 2025 · different sources and discharge it when needed. BESS consist of one or more batteries and can b We provide innovative new energy products and solutions such as smart

Essential Equipment for Energy Storage Systems: A 2025 Guide

Jan 17, 2025 · As renewable energy adoption surges (global market projected to reach $1.3 trillion by 2030 [3]), the right storage solutions make the difference between flickering lights and a

China''s Largest Grid-Forming Energy Storage Station

Apr 9, 2024 · The station was built in two phases; the first phase, a 100 MW/200 MWh energy storage station, was constructed with a grid-following design and was fully operational in June

Energy storage power station equipment basics

Feb 15, 2025 · A battery storage power station, also known as an energy storage power station, is a facility that stores electrical energy in batteries for later use. It plays a vital role in the modern

The first cabin structure''s concrete pouring for China''s

May 15, 2025 · Recently, the concrete pouring for the initial cabin structure of the 150 MW/300 MWh energy storage power station project in Andijan Region, Uzbekistan, constructed by

What equipment does the photovoltaic container energy

CESS is an important Lithium Battery technologythat can help to improve energy efficiency,promote sustainability,and increase energy resilience. How exactly does Battery

A reliability review on electrical collection system of battery energy

Nov 1, 2021 · In addition to being affected by the external operating environment of storage system, the reliability of its internal electrical collection system also plays a decisive role in the

Battery storage power station – a comprehensive guide

2 days ago · Battery storage power stations are usually composed of batteries, power conversion systems (inverters), control systems and monitoring equipment. There are a variety of battery

What equipment does the energy storage power station

Jun 12, 2024 · At the heart of energy storage power stations lies a complex network of equipment designed to store, manage, and dispatch energy. Each component possesses distinct

What equipment does the energy storage power station have?

Jul 4, 2024 · The evolution of energy storage technology has transformed the way power is generated, stored, and distributed. Energy storage power stations serve as critical

Battery Energy Storage for Electric Vehicle Charging

Sep 4, 2024 · Battery energy storage systems can enable EV fast charging build-out in areas with limited power grid capacity, reduce charging and utility costs through peak shaving, and boost

What equipment does the energy storage power station

Jun 16, 2024 · The energy storage power station cabinet is equipped with several essential components, including 1. battery management systems, 2. power conversion equipment, 3.

What technical equipment does the energy storage power station

Sep 15, 2024 · Energy storage power stations feature a range of technical equipment essential for efficient energy management. 1. Battery Storage Systems: These represent the core

Analysis of Equipment Management Methods for

Pumped-storage power stations involve various types of equipment such as hydraulic and electrical devices. The frequent start-stop operation in the context of new energy system

Battery Energy Storage储能电池及系统 System

Jun 12, 2023 · Energy储能系统(ESS) Storage System In recent years, the trend of combining electrochemical energy storage with new energy develops rapidly and it is common to move

A Simple Guide to Energy Storage Power Station Operation

Sep 3, 2024 · Energy storage power stations are facilities that store energy for later use, typically in the form of batteries. They play a crucial role in balancing supply and demand in the

Technologies for Energy Storage Power Stations Safety

Feb 26, 2024 · As large-scale lithium-ion battery energy storage power facilities are built, the issues of safety operations become more complex. The existing difficulties revolve around

What equipment does the energy storage power station have?

Jul 4, 2024 · 1. A comprehensive array of equipment is essential for the efficient operation of energy storage power stations.2. The primary components include advanced storage

6 FAQs about [Equipment inside the energy storage power station]

What are battery storage power stations?

Battery storage power stations are usually composed of batteries, power conversion systems (inverters), control systems and monitoring equipment. There are a variety of battery types used, including lithium-ion, lead-acid, flow cell batteries, and others, depending on factors such as energy density, cycle life, and cost.

What types of batteries are used in a battery storage power station?

There are a variety of battery types used, including lithium-ion, lead-acid, flow cell batteries, and others, depending on factors such as energy density, cycle life, and cost. Battery storage power stations require complete functions to ensure efficient operation and management.

What is a stationary energy storage system?

6 The term stationary is used to denote energy storage systems not contained in an electric vehicle. 7 See for instance New York’s Energy Storage System Permitting and Interconnection Process Guide For New York City Lithium-Ion Outdoor Systems

What is the construction process of energy storage power stations?

The construction process of energy storage power stations involves multiple key stages, each of which requires careful planning and execution to ensure smooth implementation.

What is a pumped storage power station?

The pumped storage power station consists of two circular concrete silos, each of about 32 metres (105 ft) internal diameter. Each of the silos houses a 250 megawatts (340,000 hp) turbine generator and pump set, giving a total capacity of 500 megawatts (670,000 hp).

Why do battery storage power stations need a data collection system?

Battery storage power stations require complete functions to ensure efficient operation and management. First, they need strong data collection capabilities to collect important information such as voltage, current, temperature, SOC, etc.

Learn More

- Equipment inside the energy storage power station

- Main equipment of energy storage power station

- Finland power station energy storage equipment transformation plan

- Energy storage power station equipment configuration

- Energy storage equipment power station superior unit

- Equatorial Guinea power station energy storage equipment quotation

- Port Moresby Photovoltaic Energy Storage Power Station Equipment Manufacturer

- Energy storage power station supporting equipment

- Japan s first energy storage power station is successful

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.