Kinetics of Oxygen Evolution Reaction in Soluble Lead Flow Batteries

Dec 12, 2024 · Request PDF | Kinetics of Oxygen Evolution Reaction in Soluble Lead Flow Batteries | Kinetics of oxygen evolution reaction (OER) on PbO2 deposited glassy carbon disk

A novel flow battery—A lead-acid battery based on an

May 15, 2008 · The structure of thick lead dioxide deposits (approximately 1 mm) formed in conditions likely to be met at the positive electrode during the charge/discharge cycling of a

High-potential zinc–lead dioxide rechargeable cells

Sep 1, 2012 · A zinc–lead dioxide rechargeable cell with an electrolyte composition of 1.5 mol dm−3 Zn (II), 0.5 mol dm−3 Na (I) and 0.3 mol dm−3 sulfuric acid is proposed and tested. The

A two dimensional numerical model of the membrane-divided soluble lead

May 1, 2021 · 1. Introduction The soluble lead flow battery (SLFB) is a hybrid flow battery in which solid lead is electroplated onto the negative electrode and solid lead dioxide is electroplated

Review—Recent Developments and Challenges in Membrane-Less Soluble Lead

Apr 20, 2022 · Soluble lead redox flow battery (SLEFB) is attractive for its undivided cell configuration over other flow battery chemistries, which require an expensive

Mechanistic Insights into Degradation of Lead Dioxide

May 26, 2025 · Recent research has extended the cycle life of the soluble lead redox flow battery to several hundred cycles at the laboratory scale. These improvements have largely resulted

Flow Batteries | Wiley Online Books

Jan 9, 2023 · Flow Batteries The premier reference on flow battery technology for large-scale, high-performance, and sustainable energy storage From basics to commercial applications,

Life-cycle analysis of flow-assisted nickel zinc-, manganese dioxide

Mar 1, 2015 · This paper presents a comprehensive literature review and a full process-based life-cycle analysis (LCA) of three types of batteries, viz., (1) valve-regulated lead-acid (VRLA), (2)

Lead-Based Flow Battery Based on New Pb

Jun 17, 2024 · Here, we design a PbBr (H 2 O) n+ -based anolyte with solubility up to 2.4 mol L –1, fast metal ion transport, and excellent kinetic properties to

Lead batteries for utility energy storage: A review

Feb 1, 2018 · A selection of larger lead battery energy storage installations are analysed and lessons learned identified. Lead is the most efficiently recycled commodity metal and lead

Lead dioxide modified graphite felt electrode of all

Lead dioxide-modified all-vanadium redox flow battery graphite felt electrode and preparation method thereof, the graphite felt electrode surface is coated with lead dioxide coating, and the

The performance of a soluble lead-acid flow battery and its comparison

Nov 1, 2011 · Following a large number of charge/discharge cycles, a soluble lead-acid flow battery could fail due to cell shorting caused by the growth of lead and lead dioxide deposition

Oxygen evolution on alpha-lead dioxide electrodes in

Feb 29, 2012 · Both EIS and CVA revealed that OER on lead dioxide is less favoured in MSA than in sulphuric acid. It is finally concluded that a high-concentrated MSA electrolyte is better for

Undivided Copper–Lead Dioxide Flow Battery Based on

Jan 6, 2023 · An undivided unit cell based on copper and lead ions in methanesulphonic acid is considered as a hybrid-flow battery. The flow cell used a single flow loop recirculating 250 cm

A novel flow battery—A lead-acid battery based on an

May 15, 2008 · The electrolyte is methanesulfonic acid in which Pb (II) is highly soluble (around 2.6 M). The key advantage of this battery, compared to other redox flow batteries, is that no

A novel flow battery: A lead acid battery based on an electrolyte

Mar 15, 2010 · The design of a 10cm×10cm flow cell for the soluble lead acid flow battery is described. A number of extended charge/discharge cycling experiments are

A novel flow battery: A lead acid battery based on an

Mar 4, 2025 · The deviation of the charge efficiency from 100% also leads to accumulation of lead on the negative electrode. The accumu-lation of lead and lead dioxide on the two electrodes

A novel flow battery—A lead acid battery based on an

Sep 26, 2005 · Abstract The performance of an undivided flow battery based on the Pb (II)/Pb and PbO 2 /Pb (II) couples in aqueous methanesulfonic acid as a function of state of charge,

Stabilizing the electrodeposit-electrolyte interphase in soluble lead

Feb 10, 2018 · The soluble lead flow battery (SLFB) is a promising energy storage system. In comparison to conventional flow batteries, the membrane-less and single-

BatteryStuff Articles | The Lead Acid Battery Explained

Aug 6, 2020 · BatteryStuff Knowledge Base Article explaining how a standard lead acid battery works. What is electrolyte? How do you charge a battery? Answers to these and more in the

Electrochemical Behavior of Polyaniline Microparticle

Dec 27, 2013 · Therefore, PANI microparticle suspension is used as anode material to fabricate the lead dioxide flow battery. The cycle performance of the lead dioxide flow battery has been

Lead Acid Battery: How It Produces Electricity Explained In A

Mar 26, 2025 · In summary, a lead acid battery produces electricity through the chemical reactions of lead and lead dioxide with sulfuric acid, leading to the flow of electrons and

6 FAQs about [Lead Dioxide Flow Battery]

What is a novel flow battery?

A novel flow battery: a lead acid battery based on an electrolyte with soluble lead (II) Part IV. The influence of additives J. Collins, G. Kear, X. Li, C.T.J. Low, D. Pletcher, R. Tangirala, et al. A novel flow battery: a lead acid battery based on an electrolyte with soluble lead (II) Part VIII. The cycling of a 10 cm × 10 cm flow cell

How to develop electrolyte for a soluble lead redox flow battery?

Developing electrolyte for a soluble lead redox flow battery by reprocessing spent lead acid battery electrodes The filter-press FM01-LC laboratory flow reactor and its applications Electrochim. Acta, 163 ( 2015), pp. 338 - 354 Numerical and experimental studies of stack shunt current for vanadium redox flow battery

Is soluble lead flow battery better than other chemistries?

Conclusions and future work The soluble lead flow battery offers some advantages over other chemistries due to the single active species, Pb 2+.

Which acid is best for soluble lead flow battery?

MSA is a well understood acid that has become very popular in electroplating applications. Because of this, its high conductivity, high metal salt solubility and overall safer nature, it is clear that MSA is the acid of choice for the soluble lead flow battery. 3.4. Electrolyte density and viscosity

Does flow rate affect soluble lead flow battery performance?

There is little work regarding the flow rate in the soluble lead flow battery. Understanding the relationship between flow rate and cell performance is important, as this could minimise the pump power whilst maintaining good electrochemical performance.

What is soluble lead redox flow battery (slrfb)?

Among various RFBs, soluble lead redox flow battery (SLRFB) is especially attractive because it operates with a single electrolyte without requiring any membrane and is considered a cost-effective system. Due to its modular design, its fabrication and maintenance cost is comparatively less. 1 Table I. Status of some major RFB systems.

Learn More

- Zinc manganese dioxide flow battery

- Performance Lead Carbon Capacitor Battery Energy Storage

- Freetown All-Vanadium Redox Flow Battery Electrolyte

- Flow battery manufacturing equipment price

- How much does a mini solar base station flow battery cost

- Is flow battery a new energy source

- Communication base station flow battery technology and management

- Communication base station flow battery cost details

- Iron-based liquid flow battery energy storage system

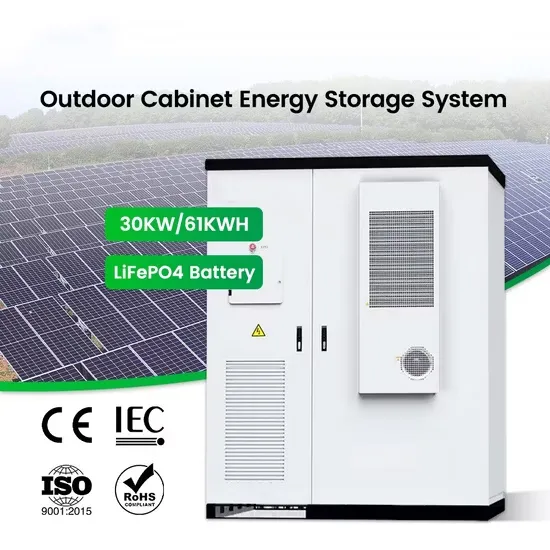

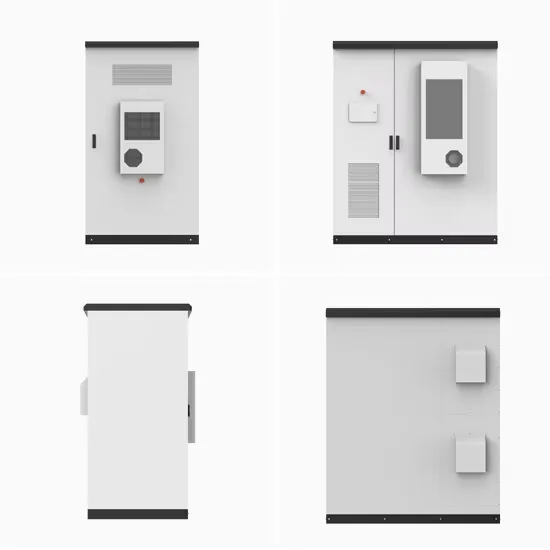

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

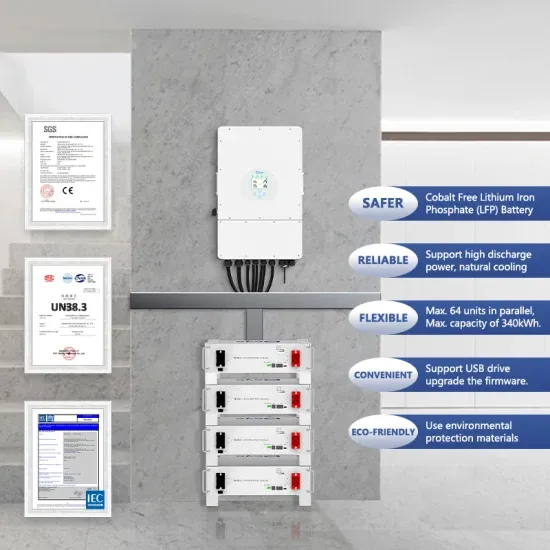

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.