Hazardous Waste Generator Regulations Compendium

Jan 6, 2022 · Please note that the Hazardous Waste Generator Improvements rule of 2016 created new sections in Part 262, which contains the regulations pertaining to generators.

Optimizing Thermal Management in Generators for Agriculture

Aug 9, 2025 · By implementing these measures, Generators for Agriculture can achieve optimal thermal equilibrium, ensuring uninterrupted power supply for automated feeding systems,

Cat Enclosures | Cat | Caterpillar

Aug 19, 2025 · From standard ISO containers to acoustic generator enclosures, our experienced Caterpillar engineers will work with you to design a custom, assembled enclosure for your

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · In conclusion, designing an efficient cooling system for 5MWh BESS containers is essential to ensure optimal performance, safety, and longevity of the battery cells. By

(PDF) Prediction of the very-and ultra-large Container Ships

Container ships represent the fastest growing segment of global shipping. Tackling such challenges as the constant pursuit of reduction of unit transportation costs and negative effects

Thermo King SG-5000 | Generator Sets | Triton Containers

Pin-mount system with clamp provision (clamp option). For easy attachment and detachment from container box. NEW! Track and Trace options available. NOTE: The dimensions and door

5D Thermal Aerosol Generator

Sep 19, 2024 · The 5D Thermal Aerosol Generator is designed for operators who require a wide range of aerosol output concentrations to perform leak tests on smaller clean air cabinets

Hazardous Waste Treatment, Storage, and Disposal

Jun 25, 2021 · These requirements are located in Title 40 Code of Federal Regulations (CFR), Part 264 for permitted facilities and 40 CFR Part 265 for interim status facilities. The

Thermo King SG-5000 | Generator Sets | Triton Containers

The container displayed only represents a sample of the entire fleet. The following items are registered or unregistered service marks in the United States and/or foreign jurisdictions

Buy Thermo King SG-5000 Genset Online Tier 4 Standards

4 days ago · Clip-on Gensets by Thermo King Buy a Thermo King Clip-on Container Generator Set in United States Find a Thermo King''s SG-5000 generator set Online SG-5000 As a

Breakthrough in size, safety of a complete

Jul 11, 2017 · Holos Generator is transportable (by heavy lift cargo plane or truck), sealed, self-controlled, highly-efficient, affordable, and load-following, thus

Horsepower containerised generators

Apr 21, 2018 · Horsepower containerised generators [1]Snehal Ahire, [2]Babu Namboothiri K., [3]Ulhas Deutkar [1,2] Department of Mechanical Engineering, Amrita school of Engineering,

6 FAQs about [Thermal generator container]

What is a containerized generator?

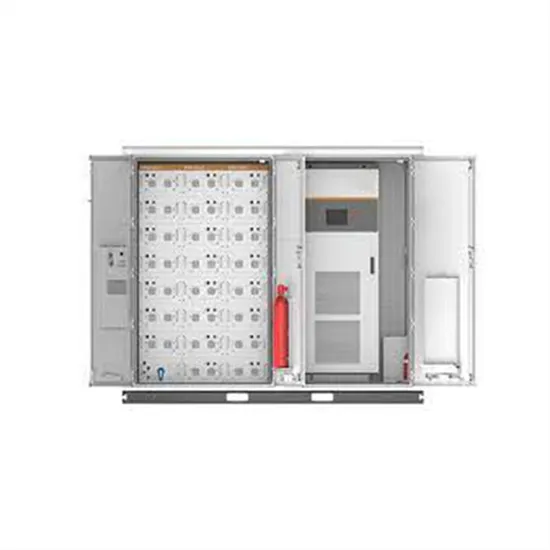

Less Maintenance The Containerized Series generator sets are designed for harsh weather and strict acoustical standards, utilizing a standard 40' high cube container equipped with an array of innovative features, allowing the system to operate reliably even in the hottest environments – validated at ambient temperatures of up to 55 degrees Celsius.

What is a Thermo King generator set?

Thermo King’s generator set (genset) range provides the vital, independent power supply needed to maintain the cold chain in global container refrigeration. They provide dependable power after your marine containers are unloaded and unplugged from the ship, ready to continue their journey on the road or waiting for further transport on shore.

What is a twin power container?

The Twin Power container solution is a container that combines two engine/alternator assemblies with/ without CHP in a 40ft container, making it perfect for applications that require variable or continuous power. Because you have two generators on a single platform, you have the flexibility you need to meet a 100% load or even a smaller load.

What are containerized generator / packaged container and enclosure options?

Containerized generator / Packaged container and enclosure options provide alternatives to installations in existing or new buildings. We have significant experience with pre-packaged container and enclosure solutions for engine-generator sets, balance of plant equipment, and switchgear.

What is a type 6 generator container?

Our Type 6 generator containers consist of two or three pre-assembled modules, depending on the engine type and the application. The overall package (gas engine, container, and auxiliary components) is available for 65, 70, 75 and 80 dB (A) in 10m (surface sound pressure level according to DIN 45635).

What gensets does Jenbacher offer?

Integrated Power Solutions. Jenbacher offers containerized generator sets based on our Type 2, 3, 4, and 6 gas engines. Leveraging the expertise acquired during several decades with more than 3,000 containerized units delivered, our genset containers offer optimal performance in various site conditions.

Learn More

- Container automatic generator

- Dili generator container

- Tuvalu container generator purchase cost

- Port Vila generator container

- Afghanistan container generator BESS

- Consult the generator container manufacturer

- Baghdad container generator manufacturer

- Comoros Custom Generator Container Factory

- Austria container temperature controlled refrigerator generator

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

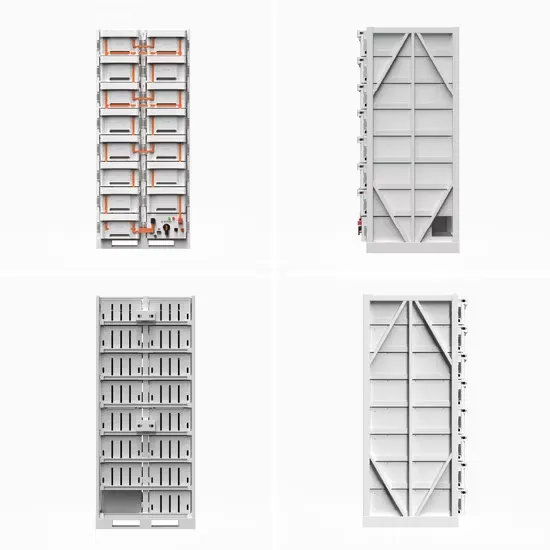

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.