Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Battery storage systems are emerging as one of the potential solutions to increase power system flexibility in the presence of variable energy resources, such as solar and wind,

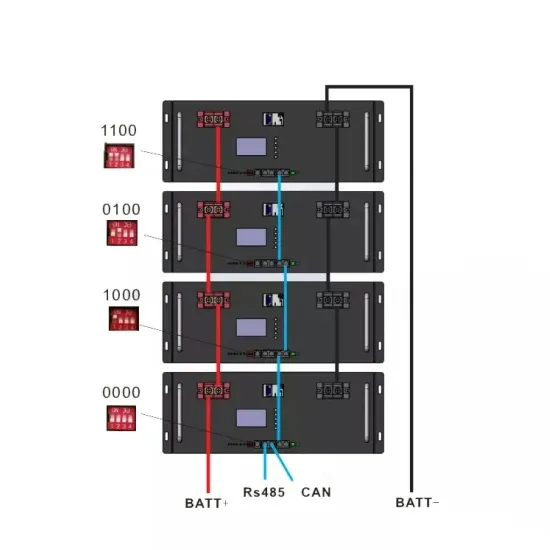

USER MANUAL BATTERY CABINET

Jul 28, 2025 · Cable sizing from the battery cabinet to the remainder of the ESS is dependent on multiple factors including the system maximum current draw, distance between the battery

General Technical Specifications and Standards for

Battery energy storage system specifications should be based on technical specification as stated in the manufacturer documentation. Compare site energy generation (if applicable),and energy

General overview on test standards for Li-ion batteries,

Nov 7, 2017 · This table covers test standards for Li-ion batteries. It is made in the European projects eCaiman, Spicy and Naiades. batterystandards

Isotech Battery Test Chambers for Safe Lithium-Ion Battery Testing

Dec 6, 2024 · The primary objective of Li-ion battery testing is to make sure battery function and safety are maintained in any environment and that high-quality batteries are produced. Li-ion

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · Amp Alternating Current Battery Energy Storage System Battery Monitoring System Bill of Lading Containerized Energy Storage System Commercial & Industrial Direct Current

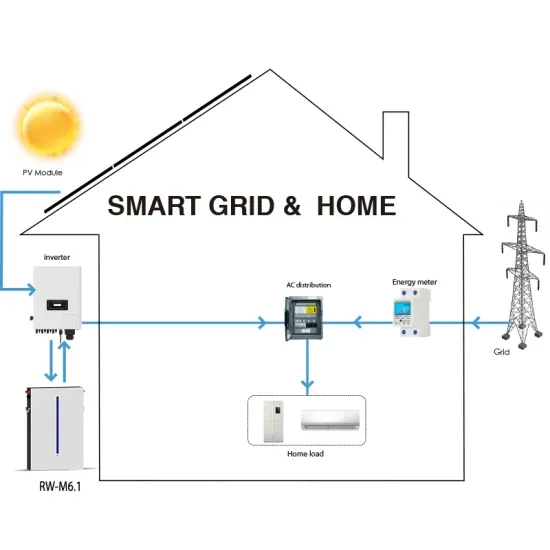

Design specifications and standards for household

Battery energy storage system specifications should be based on technical specification as stated in the manufacturer documentation. Compare site energy generation (if applicable),and energy

A Guide to Understanding Battery Specifications

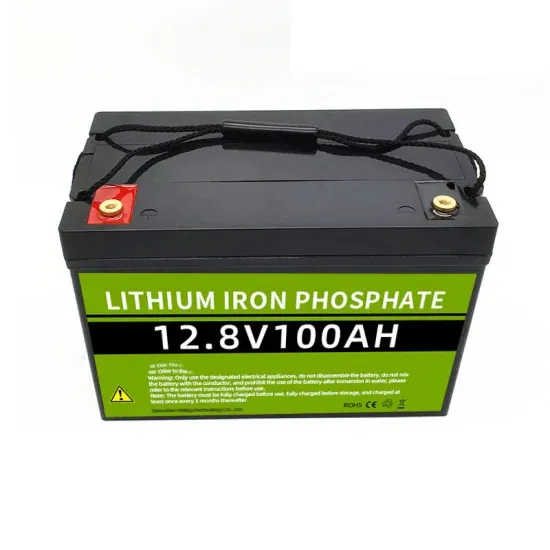

Dec 18, 2008 · A battery is a device that converts chemical energy into electrical energy and vice versa. This summary provides an introduction to the terminology used to describe, classify,

Technical Standard of Lithium-ion Battery Equipment for

Dec 12, 2024 · This document is under the charge of the CEESTA. This document specifies the technical requirements for uninterruptible power supply (UPS) battery equipment in data

ESS Battery Cell Capacity Grading Cabinet-Huiyao Laser Technology

The ESS Battery Cell Capacity Grading Cabinet is a high-precision system designed for grading energy storage battery cells based on their capacity, voltage, and internal resistance.

Samsung UL9540A Lithium-ion Battery Energy Storage

Jan 25, 2018 · The Samsung SDI 128S and 136S energy storage systems for data center application are the first lithium-ion battery cabinets to fulfill the rack-level safety standards of

Exploring Battery Testing Standards: A

Apr 8, 2024 · Battery Testing Standards play a pivotal role in ensuring the safety, reliability, and performance of batteries in electric and hybrid vehicles. These

ESS Battery Module PACK Performance Testing Cabinet

The ESS Battery Module PACK Performance Testing Cabinet is designed for high-precision electrical and thermal performance testing of energy storage system (ESS) battery modules

Standard Specifications for Lithium Battery Energy

AZE''''s 42U indoor battery rack cabinets painted with polyester powder, suitable for different brands lithium-ion batteries, it is the perfect solution for housing your Low Voltage Energy

Comprehensive Guide to Battery Aging Cabinet and

Discover the essential role of Battery Aging Cabinet and Temperature Cycling Chamber in lithium-ion battery testing. Learn about their process flow, technical specifications, and features,

Samsung UL9540A Lithium-ion Battery Energy Storage

Jan 25, 2018 · Overview The Samsung SDI 128S and 136S energy storage systems for data center application are the first lithium-ion battery cabinets to fulfill the rack-level safety

Production & Testing Solutions Battery & EV Requirements

Apr 11, 2025 · Our Production and Environmental simulators test and assess the quality, durability and performance of batteries to make sure they meet your exacting specifications and

EV Battery Cell Performance Testing Cabinet-HUIYAO LASER

Comprehensive Testing: Voltage, current, capacity, resistance, and cycle life analysis. High Precision: Accurate performance measurement under various conditions. Dynamic Testing:

ESS Battery Cell Performance Testing Cabinet-Huiyao Laser Technology

The ESS Battery Cell Performance Testing Cabinet is a high-precision system designed to evaluate the electrical and thermal performance of energy storage system (ESS) battery cells.

Eaton battery solutions brochure

Apr 3, 2025 · The IBC-SW cabinet is our newest and smallest battery cabinet of-fering, with one large string of batteries inside. This welded cabinet offers flexibility in adding runtime with a

Technical specifications and test protocols for the battery

Mar 29, 2021 · iver two 12kWh-demonstrator battery packs at TRL6 and MRL8. These aim at demonstrating the 3beLiEVe technology performance for applications in light duty (i.e.

Tesla Powerwall 2 Datasheet

Jul 2, 2024 · Tesla Powerwall 2 is a fully-integrated AC battery system for residential or light commercial use. Its rechargeable lithium-ion battery pack provides energy storage for solar

Vertiv EnergyCore Battery System

Feb 13, 2025 · EnergyCore Battery Cabinet The Vertiv EnergyCore is the first lithium-ion battery cabinet engineered specifically for data center use. Its compact design, proven safety features,

Battery Module PACK Aging Cabinet-Huiyao Laser Technology

The Battery Module PACK Aging Cabinet is designed to simulate long-term operational conditions for battery modules and PACKs. It evaluates the durability, stability, and performance of

Welcome to the website on battery standards

This website is dedicated in supporting your way through standards on rechargeable batteries and system integration with them. It contains a searchable database with over 400 standards.

L3 Series Limitless Lithium™ Battery Energy

4 days ago · The Sol-Ark® L3 Series Lithium™ battery energy storage system (BESS) offers scalability, reliability, and energy resilience essential for modern

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

Battery Pack and Module EOL test stands

Oct 8, 2024 · In battery production, the End-Of-Line (EOL) testing step is fundamental to detect any defects or deviations that may occur in the manufacturing process and to ensure that any

EV Battery Cell Performance Testing Cabinet-HUIYAO LASER

The Battery Cell Performance Testing Cabinet is designed for comprehensive performance evaluation of battery cells, ensuring high reliability and precision. It supports tests for electrical,

Lithium-ion Battery Storage Technical Specifications

Apr 21, 2022 · 1 Lithium-ion Battery Storage TechnicalSpecifications DISCLAIMER This technical specification is intended as a resource only. It is the responsibility of Government staff to

Technical Specifications and Standards for Battery Thermostatic Cabinets

• Battery energy storage system specifications should be based on technical specification as stated in the manufacturer documentation. • Compare site energy generation (if applicable),

Galaxy VS UPS for External Batteries Technical

May 8, 2025 · Legal Information The information provided in this document contains general descriptions, technical characteristics and/or recommendations related to products/solutions.

6 FAQs about [Battery Cabinet Testing Technical Specifications]

What temperature should a battery pack be tested at?

Capacity test at different temperatures and discharge ratesFor high-power battery packs and systems, the test has to be performed at three different temperatures (40 °C, 0 °C and −18 °C) with the discharge rates 1C,

What is a standard cycle in a battery test?

tem. A standard cycle has to be performed before each test. It is composed of a standard discharge, a rest period, and a standard charg h60 inpack and syste rer3.4.3. Performance TestsEnergy and Capacity test at RTFor high-power battery packs and systems, the constant current discharge rates range from 1C to 10C and

What are the technical specifications of a high-voltage battery?

ule level (section 3.3), and pack level (section 3.4 . 2. Technical specifications of the high-voltage batteryThe technical specifications of the high-voltage battery are erived from the requirements explained in deliverable D1.1. Those technical specifica ions are related to cell, module, sensors and system level. This se

How to test a battery system round-trip efficiency?

t is to determine the battery system round-trip efficiency. The test is performed at three different temperatures: RT, 40 ° , 0 °C, and three different SOC levels: 65%, 50%, and 35%. A rest pe iod of 30 min is inserted before each power p

What is the value of internal battery resistance?

to the ratio between the full-charge voltage at battery terminals and the internal battery resistance. The value of the internal resistance depends on the cell’s geo etry and construction and on the operating conditions. The common resistance range is 0.5-10 mΩ/cell.From a safety perspective,

What are the specifications for the 3believe battery pack?

.1 Consolidated requirements for the 3beLiEVe battery pack. The specifications comprise electrica , mechanical, thermal, production, and cost specifications. These apply to the high-voltage battery, including its subs stems (e.g. battery cells, sensors, BMS, coo

Learn More

- What is the battery cabinet used for testing

- Lithium battery station cabinet foil technical standards

- Professional new energy battery cabinet testing

- How to calculate the specifications of battery cabinet and power storage cabinet

- Namibia outdoor communication battery cabinet testing equipment price

- Energy storage cabinet battery technical indicators

- ASEAN battery cabinet platform system

- Battery cabinet new energy base station power generation

- Battery cabinet dc24v1400ah

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.