Top PV Racking System Manufacturers in China

Sep 1, 2023 · Our PV racking system is designed to maximize the efficiency and performance of solar panels, ensuring optimal power output. Crafted using premium materials, our racking

Post-Lamination Manufacturing Process Automation for

Aug 9, 2013 · Spire is addressing the PVMaT project goals of photovoltaic (PV) module cost reduction and improved module manufacturing process technology. New cost-effective

Top 10 Photovoltaic Panel Conveyor Manufacturers Industry

Conclusion Selecting the right photovoltaic conveyor manufacturer requires balancing technical specs, service quality, and future-proof capabilities. With solar panel demand projected to

Photovoltaic panel conveyor manufacturer

About Photovoltaic panel conveyor manufacturer As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic panel conveyor manufacturer have become critical to

Photovoltaic Rack Factory, Custom Photovoltaic Rack

Looking for photovoltaic rack factory direct sale? You can buy factory price photovoltaic rack from a great list of reliable China photovoltaic rack manufacturers, suppliers, traders or plants

Enertrack Technology Co., Ltd.,PV racking,Fixed racking

该系统适用于分布式大型工商业平屋顶和家庭平面屋顶电站,主体采用预镀铝镁锌钢制材料,安装形式为水泥块配重式或压载式,不破坏现有屋面无需做防水。 产品使用寿命25年以上,可根

Roller Conveyor for Solar Panel | Pioneers in

Choosing the Right Roller Conveyor for Solar Panel Manufacturing. Solar panel manufacturing is a complex and delicate process that requires careful material handling. Photovoltaic solar flat

Rail System Factory, Custom Rail System OEM/ODM Manufacturing

Looking for rail system factory direct sale? You can buy factory price rail system from a great list of reliable China rail system manufacturers, suppliers, traders or plants verified by a third-party

Industrial Lift & Construction Elevator Manufacturer

Industrial Elevators, Construction As an i ndustrial elevator Original Equipment Manufacturer (OEM), GEDA has been manufacturing industrial and construction elevators & material lifts

100MW Solar Panel Production Line Equipment for Meet

Aug 8, 2025 · YiLi PV Tech Ltd. was established in 2008 and is one of China′s pioneer manufacturers of photovoltaic module production equipment. We are a comprehensive high

Solar PV Racking,Solar Mounting System,Solar Mounting

6 days ago · Xiamen Enerack Technology Co.,Ltd. Specialized in research,design,development,production,and service of solar PV mounting systems,all solar

5 FAQs about [Photovoltaic panel conveyor rack manufacturer]

Who is solaracks?

Solaracks design, manufacture solar racking system to support solar projects in every sector. We provide value to our customers through competitively priced products, responsive support, robust engineering services, certified quality, and supply-chain excellence.

What is enerack pole solar mounting system?

Enerack pole solar mounting system have different angles options of 3, 4, 6, 8 panels. Simple design is ideal for remote off-grid applications such as water pumps for farm, or small residential and commercial systems etc. It can meet the customers need different angles and power generation.

Who is enerack?

We will try our best to become a world leading level of solar photovoltaic systems integration solutions supplier. Enerack owns a factory, more than 80skilled workers, have over 15 years solar products production experience. With a complete R& D processing and high manufacturing capacity.

What is solaracks methodology?

Solaracks methodology is credit and efficiency. The optimized solar mounting system, technical support, validated learning, close to end user, branding, after sales service is credit. Cost, fast delivery, swift flexible supply chain, nearby warehouse, rapid response to market feedback is efficiency.

Who is Xiamen enerack technology?

Xiamen Enerack Technology Co., Ltd. located in Xiamen city. Specialize in research, design, development, production, and service of solar PV Mounting systems.

Learn More

- Photovoltaic panel rack manufacturer

- Addis Ababa 580W photovoltaic panel manufacturer

- Mongolia folding photovoltaic panel manufacturer

- Minsk photovoltaic panel agent manufacturer

- Sri Lanka photovoltaic panel installation manufacturer

- Photovoltaic integrated panel manufacturer in New York USA

- Small solar photovoltaic panel manufacturer in New Delhi

- Photovoltaic panel medium voltage board accessories manufacturer

- Kigali rooftop photovoltaic panel manufacturer

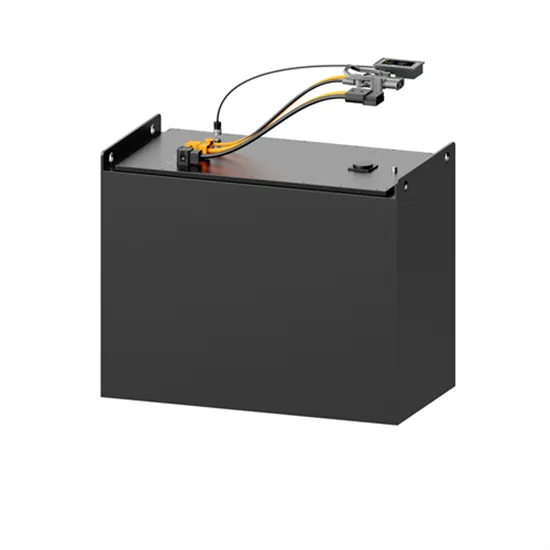

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.