A variable pressure water-sealed compressed air energy storage

May 1, 2024 · For compressed air energy storage (CAES) caverns, the artificially excavated tunnel is flexible in site selection but high in sealing cost. A novel concept of building a water

Compressed Air Energy Storage

3 days ago · Thermal mechanical long-term storage is an innovative energy storage technology that utilizes thermodynamics to store electrical energy as thermal energy for extended periods.

HICAES – Hydro-Pneumatic Isothermal Compressed Energy Storage

Jul 31, 2025 · The rapid global shift to intermittent renewable energies requires viable utility-scale energy storage for uninterrupted power supply. Hydropneumatic Isothermal Compressed Air

Compressed Air Energy Storage | Keep Energy Systems

Modular long-duration energy storage using heat and pressurised air, offering zero-emission power conversion and up to 65% efficiency. Keep Energy Systems is developing a stationary,

Why Can High Pressure Air Store Energy? The Science

May 4, 2023 · When you compress air, you''re forcing molecules into a smaller space, which raises their kinetic energy. This stored energy can later be released to do work—spinning

Compressed Air Energy Storage (CAES) for Home

Feb 25, 2025 · We design and manufacture Compressed Air Energy Storage (CAES) systems for residential applications. Combined with our turbine boosted flywheel, it can save huge

A review of thermal energy storage in compressed air energy storage

Dec 1, 2019 · During energy release process, the high pressure air stored in the compressed air storage first passes through the combustion chamber, burned mixed with fuel and become

Compressed-Air Energy Storage Systems | SpringerLink

Dec 17, 2019 · The utilization of the potential energy stored in the pressurization of a compressible fluid is at the heart of the compressed-air energy storage (CAES) systems. The

World''s largest compressed air grid "batteries"

Apr 30, 2021 · California is set to be home to two new compressed-air energy storage facilities – each claiming the crown for world''s largest non-hydro

Advanced Compressed Air Energy Storage Systems:

Mar 1, 2024 · Compressed air energy storage (CAES) is an effective solution for balancing this mismatch and therefore is suitable for use in future electrical systems to achieve a high

Research progress of compressed air energy storage and its

3 days ago · Abstract: Compressed air energy storage(CAES) is an energy storage technology that uses compressors and gas turbines to realize the conversion between air potential energy

Compressed Air Energy Storage | SpringerLink

May 1, 2025 · The use of compressed air techniques for the storage of energy is discussed in this chapter. This discussion begins with an overview of the basic physics of compressed air

How Compressed Air Storage Can Power Your Home (Real

Jun 14, 2025 · A successful home compressed air energy storage system requires several essential components working in harmony. The primary element is a high-pressure storage

Compressed air energy storage systems: Components and

Feb 1, 2021 · The investigation thoroughly evaluates the various types of compressed air energy storage systems, along with the advantages and disadvantages of each type. Different

Compressed Air Energy Storage for Home: The Future of

As renewable adoption surges globally, compressed air energy storage for home systems emerges as the missing link between solar panels and reliable 24/7 power. Unlike traditional

Compressed Air Energy Storage

5 days ago · Background Compressed Air Energy Storage CAES works in the process: the ambient air is compressed via compressors into one or more storage reservoir (s) during the

6 FAQs about [Home high pressure air energy storage]

How does compressed air energy storage work?

CAES stores potential energy in the form of pressurized air. When the air is released, it expands and passes through a turbine, which generates electricity. The amount of electricity generated depends on the pressure and the volume of the compressed air. What is the problem with compressed air energy storage?

What are the advantages of compressed air energy storage?

Advantages of Compressed Air Energy Storage (CAES) CAES technology has several advantages over other energy storage systems. Firstly, it has a high storage capacity and can store energy for long periods. Secondly, it is a clean technology that doesn't emit pollutants or greenhouse gases during energy generation.

What is compressed air energy storage (CAES)?

Compressed Air Energy Storage (CAES) technology offers a viable solution to the energy storage problem. It has a high storage capacity, is a clean technology, and has a long life cycle. Additionally, it can utilize existing natural gas infrastructure, reducing initial investment costs. Disadvantages of Compressed Air Energy Storage (CAES)

How does energy storage work?

Store the compressed air in facilities. Release the stored energy when demand increases. This innovative energy storage approach employs advanced CAES technology to compress air efficiently. The stored air remains under high pressure in cavernous formations or specialized tanks, ensuring energy efficiency.

What is the efficiency of a compressed air based energy storage system?

CAES efficiency depends on various factors, such as the size of the system, location, and method of compression. Typically, the efficiency of a CAES system is around 60-70%, which means that 30-40% of the energy is lost during the compression and generation process. What is the main disadvantage of compressed air-based energy storage?

Where is compressed air stored?

The compressed air is stored in a reservoir, typically a large underground cavern, where it can be stored for long periods until needed. When the electricity demand is high, the compressed air is released and passes through a turbine that generates electricity. The process of compressing air generates heat, which is normally wasted.

Learn More

- Stockholm energy storage battery pressure and high pressure

- Can Huawei s Brussels energy storage battery be used at home

- United Arab Emirates Home Energy Storage System Company

- Energy storage battery home safety distance

- Home 3000W energy storage

- Home energy storage products are used in

- Austrian home energy storage

- Lima Home Energy Storage Battery Company

- How much does a home energy storage system cost

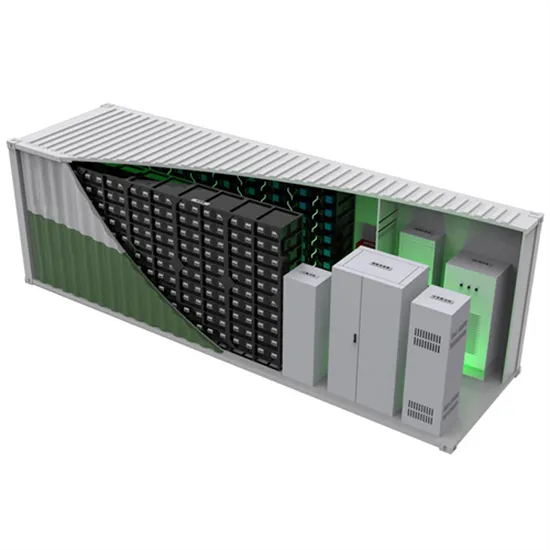

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

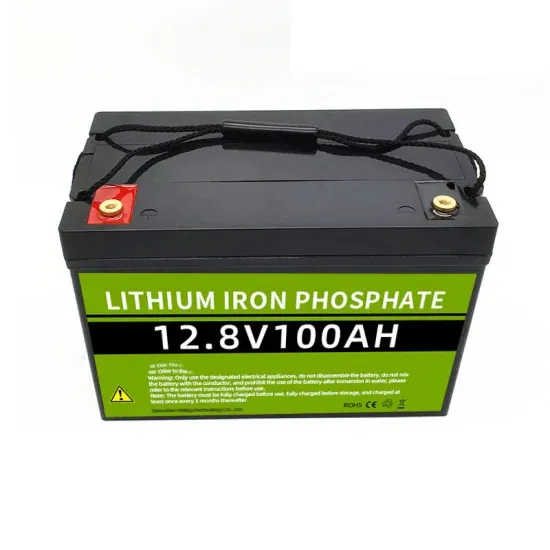

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.