Powering Doorbell with 15 VDC from existing Doorbell

Jul 4, 2021 · Using this device makes it possible to quickly run from 15 vdc power. DROK 090187 DC-DC Volt Buck Converter Step-down Regulator 8-50V 12V/24V/36V to 5V 3A Power Supply

Is 15 Volts Safe for a 12 Volt Battery – Wistek

Apr 15, 2025 · For most types of 12 volt batteries, 15 volts is too high and can lead to overcharging, overheating, and potential failure. There are limited

DC 12v AC 120V 60HZ Pure sine Wave 3000w Solar Power Inverter

Buy DC 12v AC 120V 60HZ Pure sine Wave 3000w Solar Power Inverter with Remote Switch&Soft Start for Home (DC12V (Range 10V-15V) 3000W): Power Inverters -

Could you use an inverter generator as a battery charger?

Dec 29, 2021 · The 12V DC charger socket on inverter gen is generaly around 10A or less. They are not regulated at all & will go as high as 15V or more as the battery reaches full charge, so

Can you use a 12v adapter for a 15v device?

Plugging in a 12V input to a device that requires 15V will not cause any damage assuming the polarity is correct; however, if you undervolt an amplifier, clipping or other distortion may occur.

Can you use a 12 volt adapter on a 15 volt device?

Oct 3, 2023 · No you shouldn''t use a 14 volt 5 amp adapter on a 12 volt 5 amp device unless you know for sure that the 12 volt device has an internal voltage regulator that will lower the

Can a 12V Inverter Be Connected to a 15V Power Source Voltage

Apr 8, 1971 · Connecting a 12V inverter to a 15V power source is like trying to fit a square peg into a round hole – technically possible, but risky. This voltage mismatch question frequently arises

What does a power inverter do, and what can I use one for?

The inverter draws its power from a 12 Volt battery (preferably deep-cycle), or several batteries wired in parallel. The battery will need to be recharged as the power is drawn out of it by the

Why would you want the option of 15 volts on a nominal 12-volt

In summary, a 15V option can be beneficial for specific charging scenarios, voltage drop compensation, and powering certain types of equipment. However, it''s essential to understand

Power on the Go: Can I Run My Laptop Off a 12V Battery?

Sep 28, 2024 · What is an inverter, and how is it different from a DC-DC converter? An inverter is an electronic device that converts the 12V DC power from a battery to AC power, which can

12V, 15V, 18V, 24V

Sep 8, 2020 · Three of those voltages are related to the nominal voltage available from storage batteries, while the 15 volt standard was used for analog IC devices and semiconductor analog

Adding a 48v inverter to an existing 12v system

Oct 28, 2024 · To change from one inverter output to the other you would need an AC transfer switch. To get one leg of 120V out of a split phase inverter you could use a autotransformer.

Is 13.4 volts too high for devices requiring 12 V?

Jun 27, 2020 · Page 1 of 3 - Is 13.4 volts too high for devices requiring 12 V? - posted in Equipment (No astrophotography): I bought a Jackery 500 battery

Can I use a 15V power supply on a 12V device?

Oct 3, 2023 · As long as you always take care to check the output voltage with a voltmeter first, to be sure that the voltage from the adapter is regulated, meaning that it does not rise when a

Can I use a 15V power supply on a 12V?

Nov 10, 2020 · Can a 12V power adapter be used on a 1.5A device? The device 12 V 1.5 A, means that it wants a fixed 12 V and at most, will use 1.5 Amps current flow when running with

Can a Desktop Computer run off of a dc battery

Sep 8, 2021 · 1 so I have my room setup to run off a dc battery, and the battery itself is charged via a solar panel. I currently use an inverter to power my pc

12V to 15V or 30V inverter

Apr 30, 2007 · Many people with the more usual 12V setup (including me) use a 12VDC to 240VAC inverter connected to a smart charger. Operates perfectly. All you need is a 12VDC to

Caravan Power Systems – What you need to know

Sep 23, 2020 · With this system, high powered appliances such as Air Conditioning, hairdryers, coffee machines will not be available unless a separate 240v circuit has been included, which

How bad, if at all, is 14.4V overvoltage for 12V inverter?

May 9, 2023 · In general, 12v inverters will be ok with automotive voltages which can go up past 14.4volts. But you should always check the inverter (or any equipment) for their input voltage

Can I use a 12v power supply on a 15V device?

Mar 6, 2020 · Can I use a 12v power supply on a 15V device? Onus : Assuming the polarity is correct, plugging in a 12V input to a device requiring 15V won''t do any damage, however if you

6 FAQs about [Can a 12 volt inverter be powered by 15v]

What is the input voltage for a 12V inverter?

The 12V inverter, also known as an inverter 12v a 220-125V 600W, uses 12V as its input voltage.

Can I use a 12V adapter with an 18v battery?

Yes, assuming it’s a regulated voltage supply, the device will maintain 12V, and it will draw more than 12A (5A mentioned in the passage). Using a 12V adapter with a 12V device that requires more than 12V is not recommended. If you have an 18V power source and need to use it with a 12V device, you can always use a DC-DC converter.

How many Watts Does a 12 volt inverter need?

To handle a 2000-watt load, an 12-volt inverter would need approximately 167 amps (2000 watts / 12 volts). At the full 1,000 watts of load, the input may need up to 1,050 watts or so. But there is usually a little more loss and some voltage drop in the wires. So, if this is a 12-volt inverter, you can get a reasonable estimate of the current needed by just dividing the output watts by 12.

Can I use a 14V adapter instead of a 12V one?

Using a 14V adapter instead of a 12V one will result in higher current through the components, which can shorten their life span or damage them. Most ’12v’ supplies measure around 13.6 volts or so. Yes, you can use a 13V voltage supply instead of a 12V one, assuming it's a regulated voltage supply (most are).

Can I charge a 12V battery with a 19V power supply?

You cannot charge a 12V AGM battery directly with a 12V higher 19V Laptop power supply. A battery charger is required instead. The laptop power supply is not a battery charger, it is a fixed voltage SMPS power supply. To reduce 19V DC to 12V DC for charging a battery, you need a suitable battery charger.

What voltage is needed to charge a 12V battery?

A 12V battery can be charged up to 14.7 volts in deep discharge cycling mode to get the highest charge rate. However, the voltage must be dropped to the float voltage when the charge is complete.

Learn More

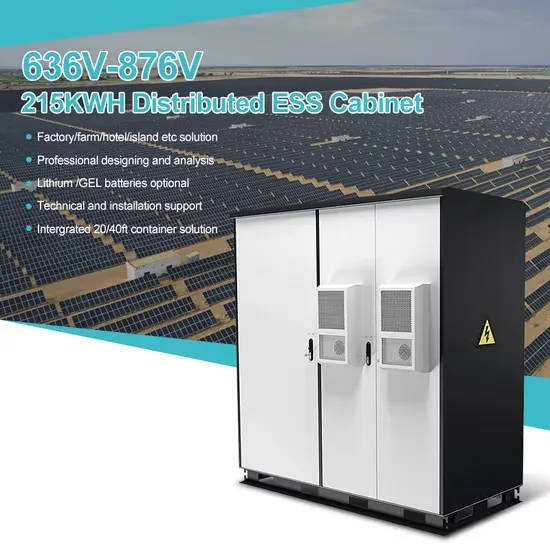

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

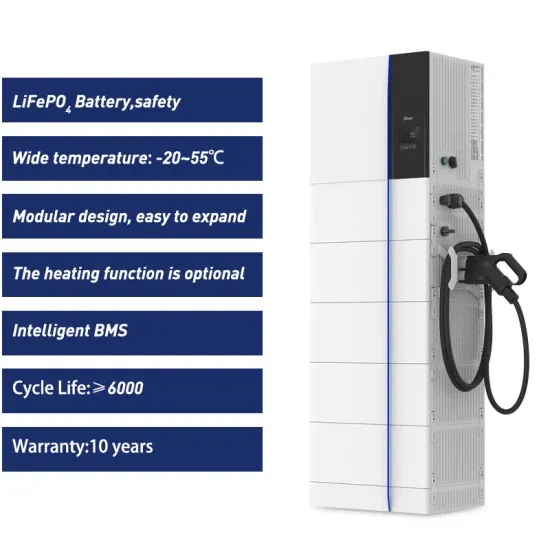

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.