What does battery rated capacity mean?-Common Problem

Jul 1, 2025 · The rated capacity of the battery refers to the capacity of the battery that can continue to work for a long time under rated working conditions. The rated capacity refers to

How is the rated energy of the energy storage cabinet

Aug 4, 2024 · Battery capacity is a critical determinant of rated energy in an energy storage cabinet. It is measured in ampere-hours (Ah) and essentially indicates the total amount of

Battery Rated Capacity and Why It Matters.

Jul 10, 2023 · Actual Capacity refers to the capacity of the battery or the power bank, whereas Rated Capacity refers to the output capacity of the power when fully charged. What That

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

Detailed explanation of the difference between

Jan 4, 2024 · Introduction to the typical capacity and rated capacity of mobile phone batteries: 1. Battery capacity generally refers to the data of the battery''s

Microsoft Word

Nov 15, 2017 · The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

Lithium-ion battery terms explained

Aug 18, 2023 · Discharge rate: refers to the current value required when releasing its rated capacity (C) within a specified time, which is numerically equal to a multiple of the rated

What is the difference between battery capacity and rated

Oct 24, 2022 · Difference: 1. Battery capacity is one of the important performance indicators to measure battery performance. It indicates the amount of electricity released by the battery

Eaton Power Xpert 9395

Sep 7, 2024 · The 9395 battery cabinet is designed to use with the 9395, 9395P, and 9395C. The primary difference is the 9395C uses an Under Voltage Relay instead of a Shunt Trip device to

What is the use of the battery in the distribution cabinet

d IP20 rated against electrical shock and foreign objects. However, the battery cabinet is a sophisticat refers only to the UPS cabinet and its internal elements. The term UPS system

What power do battery storage cabinets have

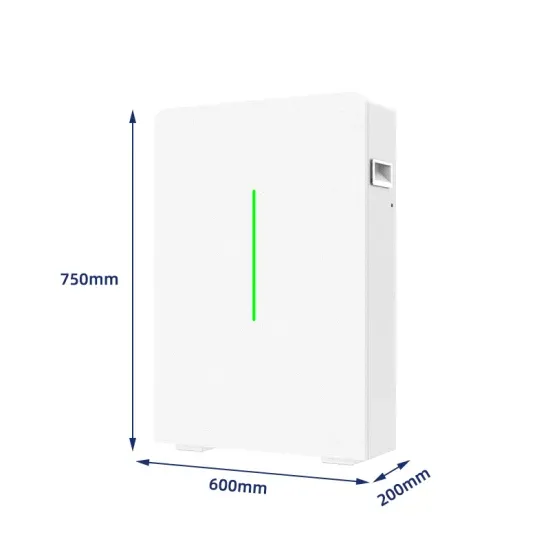

The power rating and battery capacity are key specifications that define the performance and capabilities of a battery storage system. The power rating, measured in kilowatts (kW), refers

Nominal Voltage, Rated Voltage and Operating Voltage

To ensure safe operation, the rated voltage must always be higher than the nominal voltage, and designers must consider a safety margin when determining the rated voltage. A significant

Eaton EBC Installation and Operation Manual

Sep 2, 2024 · Chapter 1 Introduction The Eaton® External Battery Cabinet (EBC) provides extended emergency short-term backup power for the 93E 80-200 kVA, 93E 300–400 kVA

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The term line-up-and-match refers to battery cabinets that are physically attached to the UPS, share internal wiring, and use the battery cabinet breaker as the battery isolation

What is Rated Power? in context of rated power meaning

Aug 30, 2024 · In the context of electrical engineering, rated power refers to the maximum amount of power that a device or system can safely handle without compromising its performance,

Eaton three-phase UPS battery handbook

Apr 3, 2025 · Battery failure is a leading cause of UPS load loss. Knowing how to properly maintain UPS batteries will help you manage your IT power more efficiently and avoid power

What is the difference between power bank battery capacity and rated

Aug 21, 2023 · A higher battery capacity means that the power bank can provide more power; 2. Rated capacity, refers to the amount of charge that the power bank manufacturer claims to be

164201687_1085_Rev_4_Web

Feb 28, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Model 1085 or 1085HR with a single battery voltage range is available to meet

6 FAQs about [The rated power of the battery cabinet refers to]

What is power rating & battery capacity?

The power rating and battery capacity are key specifications that define the performance and capabilities of a battery storage system. The power rating, measured in kilowatts (kW), refers to the maximum amount of power the system can deliver or receive at any given moment.

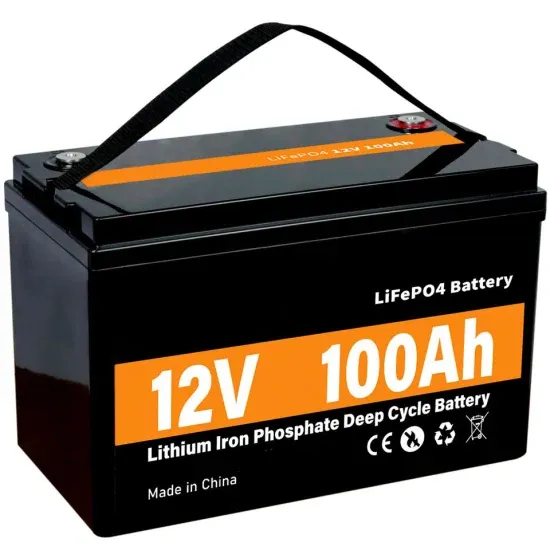

What is nominal or rated capacity of a battery?

The Nominal or Rated capacity of a battery (in Ah) is defined as the maximum Ah a fully charged battery can deliver under certain specified conditions. These conditions include: the current (or rate) at which the discharge is carried out and the battery temperature.

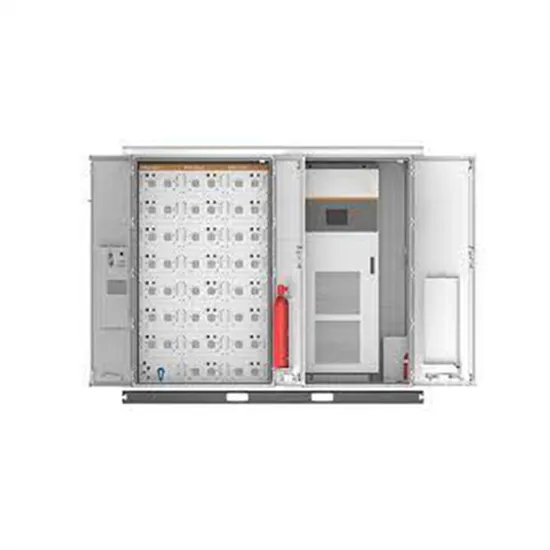

What is a battery cabinet?

A battery cabinet serves as a protective and organized enclosure for housing multiple battery modules within an energy storage system. Its primary purpose is to provide a secure environment for the batteries while ensuring their efficient operation. These cabinets are thoughtfully designed to accommodate the modules and optimize space utilization.

What is battery capacity?

This equation applies to either the charge or discharge; that is, the capacity added or capacity removed from a battery or cell. The capacity of a battery or cell is measured in milliampere-hours (mAh) or ampere-hours (Ah). Although the basic definition is simple, many different forms of capacity are used in the battery industry.

What is a power rating?

The power rating, measured in kilowatts (kW), refers to the maximum amount of power the system can deliver or receive at any given moment. It indicates the system's ability to provide electricity to meet immediate demand or accept power when charging.

What determines the capacity of a battery?

The available capacity of a battery that is able to perform work on discharge is determined by the discharge rate, endpoint voltage, temperature, battery design, age, and life history. The ‘capacity’ in watt-hours (Wh) is equal to the capacity in ampere-hours multiplied by the battery voltage.

Learn More

- Battery cabinet to outdoor power supply

- Battery cabinet base station power panel

- How much power does the battery cabinet have in total

- What are the base station power systems of the battery cabinet

- Battery cabinet maximum power calculation

- Tiraspol outdoor communication battery cabinet power

- Is the new energy battery cabinet AC power

- Is the power system of the battery cabinet base station important

- Kuwait City New Energy Battery Cabinet Professional Communication Power Supply

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.