UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Using electric storage batteries safely

Aug 20, 2024 · Using electric storage batteries safely Every year, at least 25 people are seriously injured when using batteries at work. If you or your staff work with large batteries, this booklet

Eaton-Battery-Handbook-BAT11LTA.PDF

Apr 20, 2018 · The battery or battery cabinet will also feature a sticker for each time the batteries have been recharged while in storage. Stored batteries require charging periodically during

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Understanding Battery Storage Cabinet Components and Benefits Key Components of a Battery Storage System A battery storage system is a sophisticated unit

Explosion-proof measures for battery cabinets during

Explosion safety when using lead-acid batteries Standards EN 62485-3:2014, applicable to traction batteries, and EN 62485-2:2018, applicable to stationary batteries, suggest keeping a

Why you shouldn''t charge lithium-ion batteries

May 22, 2025 · Where can you safely charge your lithium-ion (bike) batteries? And why is a safety cabinet – also known as a flammable storage cabinet –

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Jul 17, 2024 · Battery types Batteries are available in a range of technologies, including lead-acid, nickel- cadmium, lithium ion, lithium-sulfur, aluminum-ion, nickel-metal, and more. Of all these,

Inside Risk: lithium-ion battery returns – managing property

Jun 11, 2025 · Lithium-ion batteries have become both ubiquitous and essential to our modern lives. Utilised in our homes, workplaces, and transportation, lithium-ion batteries provide a

What are the standard requirements for battery energy storage cabinets

Jun 2, 2024 · Battery energy storage cabinets must comply with several critical criteria: 1. Material durability, ensuring resilience against environmental factors, 2. Adequate thermal

Considerations for Using Lithium-ion Batteries with UPS

Dec 20, 2022 · The cabinet or string aggregator and battery management system together must function within requirements for the battery to be connected to the UPS system.

Problems that need to be paid attention to in the battery storage cabinet

Mar 1, 2025 · When the battery storage system cabinets become overheated, it causes a potential safety issue since the batteries inside may degrade or even catch fire — this is something we

Battery Room Ventilation and Safety

Mar 15, 2023 · To prevent the failure and the battery dry out, the safety valves open and the battery vents hydrogen until temperature and/or voltage are reduced. This condition can be

Eaton EBC Installation and Operation Manual

Sep 2, 2024 · Chapter 1 Introduction The Eaton® External Battery Cabinet (EBC) provides extended emergency short-term backup power for the 93E 80-200 kVA, 93E 300–400 kVA

What Safety Precautions Should Be Taken When Handling Battery

What Safety Precautions Should Be Taken When Handling Battery Electrolyte? When it comes to battery maintenance, many of us may think of simply replacing batteries or recharging them.

Do Lithium Ion Batteries Require A Battery Room? Storage

Apr 16, 2025 · In summary, lithium-ion batteries do not always require a dedicated battery room; however, proper storage requirements, including temperature, humidity, and ventilation, are

Lithium-Ion Batteries and Charging Fire Risk

A 90 minute fire rating has been achieved from an international testing facility for our lithium-ion battery charging cabinets. Max 1006 degrees C was achieved inside of the cabinet whilst the

Battery Cabinet Safety Laws and Regulations

This course describes the hazards associated with batteries and highlights those safety features that must be taken into consideration when designing, constructing and fitting out a battery

Can You Use Makita Batteries On Harbor Freight Tools?

1 day ago · Makita batteries aren''t directly compatible with Harbor Freight tools. Adapters exist, but they may affect performance, safety, and tool warranty.

Microsoft Word

Nov 15, 2017 · The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

Battery Cabinet Solutions: Ensuring Safe Storage and

Lithium-ion batteries are essential in powering tools, devices, and energy systems across industries, but they also come with inherent fire and explosion risks. To address these

6 FAQs about [Batteries cannot be taken out of the battery cabinet]

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Do lithium ion batteries need a battery room?

Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements. Store batteries at a temperature of 59°F (15°C). Also, refer to NFPA 70E for further safety guidelines, and ensure proper exhaust ventilation for off-gas events.

What happens if a lithium ion battery is not stored properly?

On the negative side, improper storage can lead to serious risks. Lithium-ion batteries stored at high temperatures can swell, leak, or even catch fire. A study by the National Fire Protection Association (NFPA) in 2021 highlighted that 28% of battery fires occurred due to insufficient storage conditions.

How do you store a battery?

Humidity is another critical factor. Ideal storage conditions should maintain humidity levels below 60% to prevent corrosion and damage. Batteries exposed to high humidity can develop rust or leaks, which are hazardous. It is also important to store batteries at a partial charge.

Are battery storage systems dangerous?

There has been a fair amount of news about battery storage systems being involved in fire and explosion incidents around the world. Do not forget that these are not the only safety issues when dealing with batteries. Battery systems pose unique electrical safety hazards.

How safe is a battery room?

All electrical equipment or fittings installed in a battery room must be intrinsically safe to reduce the risk of arcing, flashing or ignition. The ventilation fans shall be provided with the single-phase squirrel-cage induction type motors suitable for direct-on-line starting.

Learn More

- What to pay attention to when installing batteries in the battery cabinet

- How to return batteries to the battery cabinet

- How to buy battery cabinet replacement batteries

- What batteries are in the battery cabinet

- Battery cabinet batteries not coming out

- Do batteries belong to the battery cabinet

- Does the energy storage battery cabinet contain lithium batteries

- Lithium battery station cabinet sea transportation

- Brief introduction to the development of battery cabinet technology

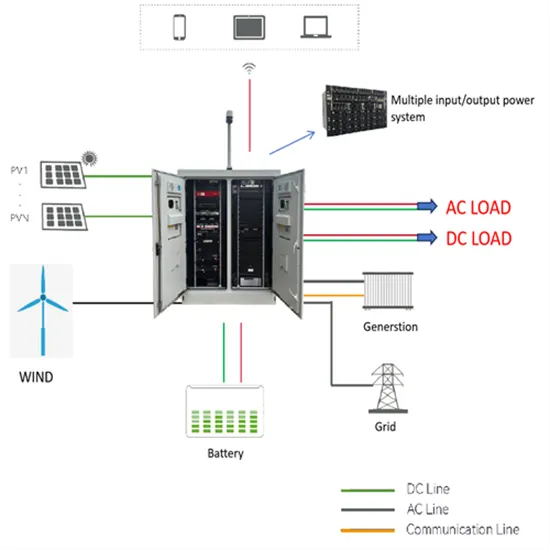

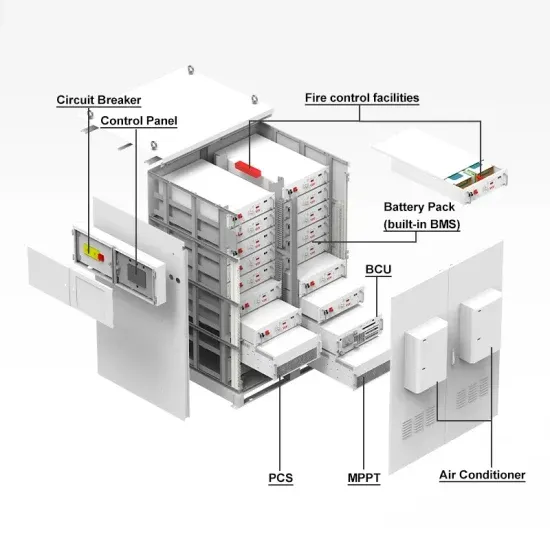

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.