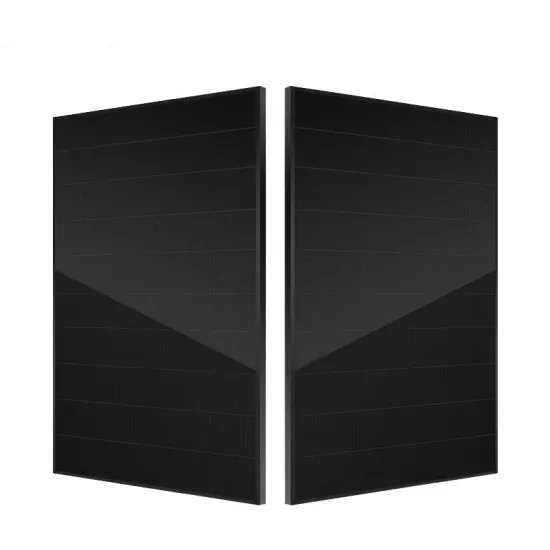

Are photovoltaic panels so fragile Why

The installation of PV panels at humid and hot climates is a factor that allows the appearance of this type of failure due to the penetration of moisture in the cell''s enclosure. The moisture

Are photovoltaic panel cells fragile and toxic

full scope of solar panel risk. Sandwiched between the protective glass, frame, and back-sheet of the solar panel, solar cells present no risk to health, but once a panel burns and the solar cells

Why are solar photovoltaic panels so fragile

Part of the reason for that is because solar panels are so fragile and easy to break, notes Kaminska, citing a solar company report pointing to "the delicate nature of solar cells themselves.

Why are solar panels fragile? | NenPower

Jan 24, 2024 · 1. UNDERSTANDING SOLAR PANEL CONSTRUCTION The essence of comprehending why solar panels are perceived as fragile lies in recognizing their construction

Japan''s new solar tech brings film-like panels to fragile

Jul 24, 2025 · Japan''s new solar film aims to power rooftops ruled out by heavy panel weight The chalcopyrite solar cells are expected to be as lightweight as perovskite solar cells.

How fragile are solar panels? –

Mar 30, 2023 · Solar panels have become an increasingly popular option for generating clean energy in the United Kingdom, but many people are concerned about their durability. After all,

Are Solar Panels Fragile?

Jul 10, 2025 · Bottom Line: Solar Panels Are Strong, Reliable, and Long-Lasting If you''re worried about panels being fragile, rest easy. These systems are built for the real world — and North

For cheaper solar cells, thinner really is better

Jan 26, 2020 · Today''s silicon photovoltaic cells, the heart of these solar panels, are made from wafers of silicon that are 160 micrometers thick, but with

Introduction to photovoltaics. Part 1: Solar cells

Jan 19, 2018 · History of photovoltaics Scientists use the term photovoltaics (PV) to talk about solar cells – the smallest fraction of the solar technology. A

How fragile are solar panels? –

Mar 30, 2023 · First, it''s important to understand that solar panels are not inherently fragile. They are designed to withstand a certain amount of wear and tear, and are built to last for decades.

Are Glass Solar Panels Fragile-JA TECH

Aug 27, 2024 · To understand whether glass solar panels are fragile, we need to first understand their basic structure. Glass solar panels, as the name suggests, use glass as the front panel

Are Solar Panels Fragile?

Aug 12, 2024 · Surrounding the PV cells are encapsulation layers, usually made of ethylene-vinyl acetate (EVA). These layers protect the cells from moisture, dirt, and physical damage while

Cheaper Solar Cells Are Possible With Thinner

Jan 27, 2020 · Today''s silicon photovoltaic cells, the heart of these solar panels, are made from wafers of silicon that are 160 micrometers thick, but with

Micro-Fracture Detection in Photovoltaic Cells with Hardware

Mar 9, 2024 · Solar energy is rapidly becoming a robust renewable energy source to conventional finite resources such as fossil fuels. It is harvested using interconnected photovoltaic panels,

Bayesian updating of solar panel fragility curves and

Jan 1, 2023 · Due to the lack of solar panel failure data or appropriate experimental tests, Goodman [13] used simplified numerical structural assessment to propose the first solar panel

Is photovoltaic panel glass easily damaged during

In addition to these reasons,solar panels can sometimes be damaged during transportation or mishandled during installation,which may not become apparent until several years after the

Flexible Solar Cells Without Rare Earth Metals

Feb 18, 2025 · Perovskite-based flexible solar cells offer a cost-effective, rare-earth-free alternative to conventional panels, improving accessibility and

6 FAQs about [Are photovoltaic panel cells fragile ]

What is photovoltaic cell degradation?

Photovoltaic cells degradation is the progressive deterioration of its physical characteristics, which is reflected in an output power decrease over the years. Consequently, the photovoltaic module continues to convert solar energy into electrical energy although with reduced efficiency ceasing to operate in its optimum conditions.

What happens if a photovoltaic module is degraded?

Consequently, the photovoltaic module continues to convert solar energy into electrical energy although with reduced efficiency ceasing to operate in its optimum conditions. According to Wohlgemuth et al. manufacturers consider a photovoltaic module degraded when its output power reaches 80% of its initial value .

Do photovoltaic cells behave in the absence of degradation?

Therefore, the accuracy of this fitting model was proven as it portrays, simultaneously, the behavior of photovoltaic cells in the absence and presence of degradation. The crystalline silicon cell is a rigid structure, and the remaining studied technologies are flexible.

Do small cracks affect the performance of a-Si photovoltaic cells?

It was noted that the a-Si cell showed an abrupt reduction in its efficiency (−92.77%) when the first crack (which had reduced dimensions) was formed. Thus, it appears that the formation of a small crack has a great impact on the performance of this photovoltaic technology.

What is a photovoltaic failure fact sheet (PVFS)?

The report explores several key areas of photovoltaic degradation and reliability, presenting both the challenges introduced by innovative technologies and the potential mitigation strategies. The report also includes an annex, the Photovoltaic Failure Fact Sheets (PVFS), which summarises some of the most important aspects of single failures.

What factors affect a photovoltaic cell?

Other factors important to highlight are physical aggressions due to rain, snow, hail and other possible mechanical shocks , , , , , , , . Aging of the photovoltaic cell and the various types of degradation have several repercussions on cell’s electric characteristics .

Learn More

- Dominica explosion-proof photovoltaic panel prices

- Latvian soft photovoltaic panel manufacturer

- Photovoltaic panel dimensioning

- 4000w photovoltaic panel price

- Which photovoltaic panel solar folding bag generates electricity faster

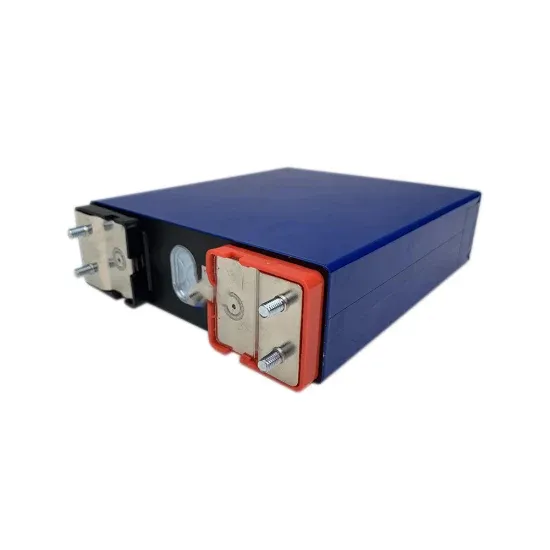

- How many batteries are needed for 1 kilowatt photovoltaic panel

- 680 photovoltaic panel output power

- How big is the photovoltaic panel of a 220w solar light

- Photovoltaic panel manufacturers in Paris

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

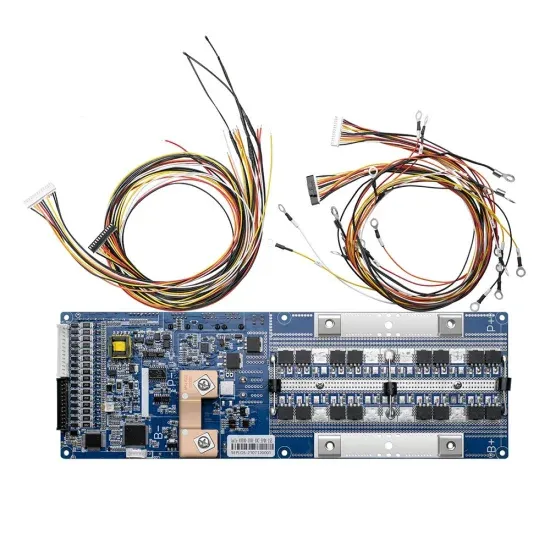

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.