Core Temperature Estimation of Lithium-Ion Batteries Using

Apr 11, 2025 · Health-conscious battery management systems (BMSs) that rely on surface temperature measurements are insufficient for managing automotive lithium-ion batteries

Core temperature estimation of lithium-ion battery based on

Nov 20, 2024 · Temperature has a critical impact on the lifespan and safety of lithium batteries. This paper proposes a battery core temperature estimation method based on numerical model

Thermal conductivity of Li-ion batteries and their electrode

Oct 1, 2017 · The automotive application of Li-ion batteries as power source for (hybrid) electric vehicles requires a thermal management system to maintain performance and ensure a safe

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Ⅰ. Introduction of cylindrical lithium-ion cell Cylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system

Time-resolved impedance spectroscopy analysis of aging in

Mar 30, 2024 · To replace the conventional internal combustion engine (ICE) vehicles on a large scale, advanced battery technology is required. Although the conventional Li-ion battery (LIB)

Thermal runaway characterization of cylindrical lithium-ion

The results indicated maximum temperatures and heating rates intermediate between the LFP and NMC batteries, questioning the safety advantages of sodium-ion batteries with NTM

18650 vs. 21700 Li-ion cells

Oct 1, 2020 · 3.4. Effects of electrode curvature in 18650 and 21700 cells The curvature of different windings in the jelly roll is also an important factor in the development of cylindrical Li

Everything about Cylindrical Batteries, the Power

May 29, 2024 · The importance of cylindrical batteries is only growing because they are used widely from small electronic devices to EVs. In line with the

Thermal runaway characterization of cylindrical lithium-ion

5 days ago · Extensive thermal runaway characterization is essential in battery development, requiring an analysis of multiple parameters for safety assessment. This paper presents an

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Understanding Cylindrical Lithium-Ion Battery

Feb 19, 2025 · In today''s technology-driven world, cylindrical lithium-ion batteries are more than just a power source—they are a fundamental component in

圆柱形锂离子电池的设计、特性和制造——概述,Batteries

Jun 3, 2023 · Design, Properties, and Manufacturing of Cylindrical Li-Ion Battery Cells—A Generic Overview Battery cells are the main components of a battery system for electric vehicle

Thermal runaway characterization of cylindrical lithium-ion

May 23, 2025 · This paper presents an approach for a comprehensive thermal runaway characterization based on experimental data from accelerating rate calorimetry (ARC) and

Cylindrical vs. Prismatic vs. Li-Po Battery: Key

Feb 29, 2024 · Curious about battery types? Learn how cylindrical, prismatic, and lithium polymer batteries stack up against each other. Make the best choice!

圆柱形锂离子电池介绍

Apr 13, 2023 · 圆柱型锂离子电池分为磷酸铁锂、钴酸锂、锰酸锂、钴锰混合、三元材料等不同体系,外壳又分为钢壳、聚合物两种,不同材料体系的电池具有不同的优势。 1.什么是圆柱形锂

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium-ion cells are usually represented by five digits unting from the left,the first and second digits refer to the diameter of

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

6 FAQs about [Dominic cylindrical lithium battery]

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

What is a cylindrical battery?

Cylindrical cells are named after their sizes (diameter in mm x height in mm). Current models of cylindrical batteries include 14650, 18650, 21700, 32650, 4680 (named by the standardised sizes of the battery, e.g. 14650 cylindrical cell is 14.5mm in diameter x 65.3mm in height).

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

Why are cylindrical battery cells so popular?

In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla tabless design. This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680).

What are the different types of cylindrical batteries?

Current models of cylindrical batteries include 14650, 18650, 21700, 32650, 4680 (named by the standardised sizes of the battery, e.g. 14650 cylindrical cell is 14.5mm in diameter x 65.3mm in height). 18650 represents the most mature technology, developed by SONY in 1992; 21700 is the most widely used cell format by Tesla EV.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

Learn More

- Is the Warsaw lithium battery cylindrical

- Cylindrical low temperature lithium battery

- Ethiopia cylindrical lithium battery

- Capacity cylindrical lithium battery

- Syria cylindrical lithium iron phosphate battery

- Lithium battery 3 6v cylindrical double

- Is the Wellington cylindrical lithium battery useful

- Tunisian cylindrical lithium battery

- Lithium battery assembled into cylindrical shape

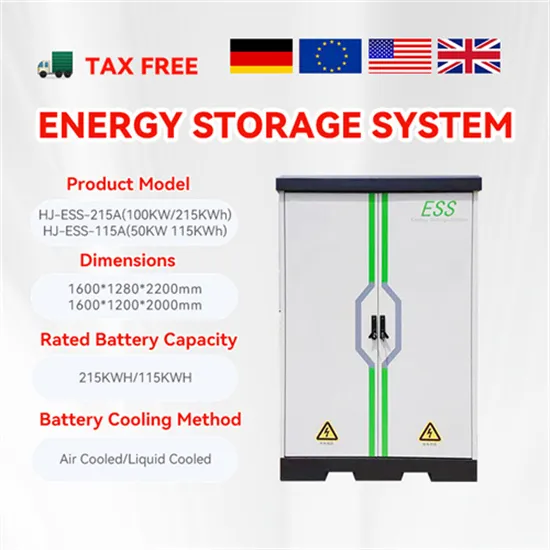

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.