A Study of the Temperature Influence on Different

Jun 16, 2021 · The results show that the temper-ature has a significant impact on the various parameters of the photovoltaic panel and it controls the quality and performance of the solar

Data on the I–V characteristics related to the SM55 monocrystalline PV

Oct 1, 2019 · The presented data are related to the article "Solar Irradiance and Temperature Influence on the Photovoltaic Cell Equivalent-Circuit Models" (Chaibi et al., 2019). Data include

Effects of substrates on the efficiency of a monocrystalline solar panel

Feb 24, 2025 · This study investigated the effects of different substrates on the efficiency of monocrystalline solar panels. The research analyzed how roofing materials impact solar panel

Comparative study with practical validation of photovoltaic

Sep 27, 2021 · The unknown internal parameters of the PV panel circuit are extracted by using the PV array tool in Simulink, which is a simple method to obtain the PV parameters at certain

Monocrystalline silicon photovoltaic panel specifications

What are monocrystalline solar panels? Monocrystalline solar panels are made from single-crystal silicon,resulting in their distinctive dark black hue. This uniform structure,with fewer grain

Types of Solar Panels: Monocrystalline vs

Jan 30, 2024 · Polycrystalline panels have a slightly shorter lifespan of 20 to 25 years but still offer a reliable source of renewable energy. Point 3: Thin-film

The effect of irradiation on different parameters of monocrystalline

May 31, 2014 · The overall performance of solar cell varies with varying Irradiance and Temperature with the change in the time of the day the power received from the Sun by the

Utilization of device parameters to assess the

Feb 3, 2023 · In this work, an assessment on the variation of intrinsic parameters of a monocrys-talline silicon photovoltaic (PV) module is carried out under varied temperature and irradiance,

Optimal parameter assessment of Solar Photovoltaic module

Nov 1, 2022 · The PV module parameter extraction is performed on different kinds of PV modules, namely, monocrystalline type Shell CS6K280M, polycrystalline type Shell S75, and thin-film

A Dynamic Monocrystalline PV Panel Model with EIS

Oct 12, 2024 · This work is aimed at estimating internal PV panel parameters under outdoor conditions by using the impedance spectroscopy technique. The impedance is measured by

Extraction of Monocrystalline Silicon Photovoltaic Panel Parameters

Sep 29, 2023 · The aim of this work is to develop models that reproduce highly precise I-V (Current-voltage) curves of photovoltaic (PV) panels, regardless of the temperature and

Experimental Investigation of Temperature Effects on the Parameters

This work presents an experimental analysis of the influence of a monocrystalline photovoltaic (PV) panels'' temperature on its main operating parameters. Victron Energy, SPM 30-12 PV

Monocrystalline photovoltaic panels: what they are and their

Dec 11, 2024 · Monocrystalline photovoltaic panels are at the forefront of solar technology due to their efficiency, durability and ability to generate energy even in confined spaces. They are

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · The monocrystalline panel is a type of photovoltaic panel characterized by high efficiency and long durability. Find out how it differs from polycrystalline panels

Extraction of Monocrystalline Silicon Photovoltaic Panel

Oct 12, 2023 · In this approach, the five parameters that are necessary for the characterization and identification of the PV module are: short-circuit current, open circuit voltage, ideality factor

Parameters of a Solar Cell and Characteristics of

3 days ago · Ideally, the angle should be 90o but practically it should be as close as 90o. The solar cell is a two-terminal device. One is positive (anode) and the

Analysis of specifications of solar photovoltaic panels

May 1, 2022 · Parameters of photovoltaic panels (PVPs) is necessary for modeling and analysis of solar power systems. The best and the median values of the main 16 parameters among

Performance evaluation of monocrystalline and

Jan 24, 2023 · PV installation for the plant For the installation of the plant two types of solar panels are selected. One is monocrystalline and the other is a polycrystalline solar panel. It

Hybrid Deep Learning Models for Power Output Forecasting

Aug 6, 2025 · Hybrid Deep Learning Models for Power Output Forecasting of Grid-Connected Solar PV Systems: A Monocrystalline and Polycrystalline PV Panel Analysis

(PDF) Impact of Temperature on the Efficiency of Monocrystalline

Dec 2, 2024 · The temperature effect over the efficiency of monocrystalline and polycrystalline photovoltaic panels by using a double-climatic chamber and a solar simulation device was

A Dynamic Monocrystalline PV Panel Model with EIS

Oct 12, 2024 · This work is aimed at estimating internal PV panel parameters under outdoor conditions by using the impedance spectroscopy technique. The impedance is measured

6 FAQs about [Monocrystalline photovoltaic panel parameters]

What are monocrystalline solar panels?

Monocrystalline solar panels, known as mono panels, are a highly popular choice for capturing solar energy, particularly for residential photovoltaic (PV) systems. With their sleek, black appearance and high sunlight conversion efficiency, monocrystalline panels are the most common type of rooftop solar panel on the market.

What is the efficiency of a monocrystalline photovoltaic (PV) panel?

With an efficiency rate of up to 25%, monocrystalline panels reach higher efficiency levels than both polycrystalline (13-16%) and thin-film (7-18%) panels. Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si).

How much power does a monocrystalline solar panel have?

The best monocrystalline solar panels have power ratings upwards of 500W, with some exceeding 600W and even 700W. In contrast, you’ll struggle to find a polycrystalline panel with a power rating above 400W, and they’ve long fallen around 20% below monocrystalline models, according to data analysts Wood Mackenzie.

What are the advantages of monocrystalline solar panels?

Monocrystalline solar panels offer a series of advantages. Thanks to their high degree of silicon purity, they are considered the most efficient. The efficiency rate, which measures the amount of solar energy converted into electrical energy, usually ranges between 12% and 19%.

What are the parameters of photovoltaic panels (PVPS)?

Parameters of photovoltaic panels (PVPs) is necessary for modeling and analysis of solar power systems. The best and the median values of the main 16 parameters among 1300 PVPs were identified. The results obtained help to quickly and visually assess a given PVP (including a new one) in relation to the existing ones.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

Learn More

- Huawei photovoltaic panel monocrystalline silicon parameters

- Monocrystalline silicon solar photovoltaic panel 400w

- Photovoltaic panel parameters

- How much does a monocrystalline photovoltaic panel cost in Sierra Leone

- Monocrystalline silicon photovoltaic panel conversion

- Photovoltaic panel size and parameters

- 275w monocrystalline photovoltaic panel price

- 12V monocrystalline photovoltaic panel

- Alofi monocrystalline silicon photovoltaic panel manufacturer

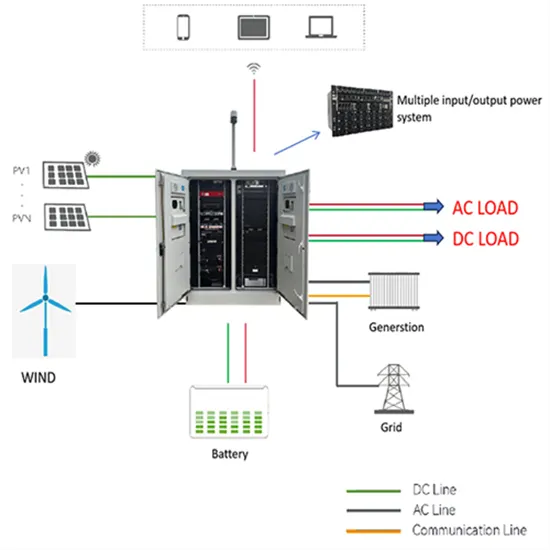

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.