How Many Watts Does an Inverter Refrigerator Use: A Closer

May 28, 2024 · An inverter refrigerator is a popular appliance that helps us keep our food fresh and cool. However, one question that often arises is, "How many watts does an inverter

Frequently Asked Questions about Inverters

Frequently Asked Questions about Inverters How much battery capacity do I need with an inverter? As a rule of thumb, the minimum required battery capacity for a 12-volt system is

Power of a washing machine consumed during washing in kilowatts (kW)

Discover how much power your washing machine consumes, factors affecting its energy usage, and tips to reduce electricity costs while keeping your clothes clean.

Inverter Usage Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · The formulas to calculate energy consumption based on inverter usage are: [ text {Daily Energy Consumption (kWh)} = frac {text {Power Rating (W)} times text {Usage Time

How much power does an Inverter use just sitting there idling?

Oct 30, 2020 · Generally a 3 kW sinewave high freq inverter is 30 to 50 watts of full idle power. A high frequency inverter has two primary stages. First stage is high frequency DC to DC

How Much Power Does a Mini Split Use: Energy

May 7, 2025 · Mini split air conditioning systems have gained popularity for their zone-based cooling capabilities and installation flexibility. One crucial factor

Analysis of Auxiliary Energy consumption in Utility scale

Sep 12, 2017 · Abstract The main concern of this paper is to investigate average daily auxiliary consumption of PV plants of various capacity & to obtain an inter-relation between them.

Analysis of Auxiliary Energy consumption in Utility scale

Sep 12, 2017 · Fig 3 suggests that auxiliary consumption of Make-B & Make-D inverters is least however other inverters are also in same range. Study of performance of inverters is also

MOST FREQUENTLY ASKED QUESTIONS ABOUT

Apr 13, 2023 · The 2-cyl Go Green APU will consume 0.2 gallons of fuel per hour under load. The same 2,500 hours of idling will cost only $1,995, saving the owner $9,975 per year on fuel alone.

How much power does an Inverter use just sitting there idling?

Oct 30, 2020 · All inverters providing ready-to-use 120VAC have an idle consumption. There is a cost to running the circuitry that generates the 120VAC and 60Hz frequency. My 4kW Victron

Auxiliaries consumption in Inverter

Mar 12, 2023 · Auxiliaries in the Inverter definition. Manufacturers have the opportunity of defining an Auxiliary consumption parameter, which represents the necessary power for cooling the

How much power does an inverter 5kw 48v consume when

May 20, 2025 · In conclusion, the idle power consumption of a 5kW 48V inverter is an important factor to consider when choosing an inverter for your power system. By understanding the

Welding Machine Power Consumption Calculator – Calculator

Sep 7, 2024 · In the world of welding, knowing about power consumption is key. It affects how efficient, cost-effective, and green welding operations are. As we aim for more efficient and

Auxiliaries consumption parameter

Aug 13, 2025 · Auxiliaries in the Inverter definition Manufacturers have the opportunity of defining an Auxiliary consumption parameter, which represents the necessary power for cooling the

Idle ''no load'' Consumption: Specs vs Your Personal Observation

Dec 10, 2019 · Dynamote Brutus 3200 watt 120v. low frequency iron core transformer 96 watts <88 watts> Brutus is an antique (1984-86??) being the very first high frequency electronics

6 FAQs about [How much kw does the inverter auxiliary equipment consume]

How much auxiliary power does a power plant use?

In other studies, various power producers have estimated the auxiliary power requirements of their units. Study of Power Plants in India: Table 15.5 summarizes an analysis of auxiliary power consumption in India’s power plants. This analysis suggests that consumption ranges from 6.33 to 8.89 percent. Table 15.5.

How to calculate solar power auxiliary power?

To accurately calculate solar power auxiliary power, one must first understand the underlying components and their interrelations. 1. Identify the total energy consumption of auxiliary systems, 2. Determine the solar panel output, 3. Assess the buffer energy storage requirements, 4. Evaluate efficiency losses during the conversion process.

What is auxiliary energy consumption in a thermal power plant?

Thermal power plants are the measure source of energy for electricity generation. In thermal power plants part of energy generated by the plants is being consumed by different auxiliaries. The power consumption by these auxiliaries is very high due to poor operation or bad design of the equipments. What is auxiliary energy consumption?

What is the auxiliary consumption of solar PV plant?

The consumption of Solar PV plants. AC capacity of PV plant of known capac ity. For would have 1.09% of total auxiliary consumption. Also wisely. Fig 3 suggests that auxiliary consumption of inverters are also in same range. Study of performance inverters. Similarly, Make- Y transformers possess least in same range but higher than Make-Y.

What are auxiliary power requirements?

UNDERSTANDING AUXILIARY POWER REQUIREMENTS Auxiliary power systems are essential in numerous applications, including residential, commercial, and industrial solar setups. Understanding the energy consumption patterns of devices and systems that rely on auxiliary power is critical for determining solar energy needs.

How much auxiliary power does a motor use?

This analysis concludes that motors used to power pumps, fans, compressors, and pulverizers account for more than 80 percent of auxiliary power consumption . Table 15.6. Breakdown of Auxiliary Power Consumption

Learn More

- How much power does a 5 kW inverter have for a motorhome

- How much does a 20 kW solar photovoltaic inverter cost

- How many volts does the inverter output voltage change

- 70 kW energy storage equipment

- 1 2 kw solar inverter factory in Karachi

- 2 5 kw solar inverter factory in Auckland

- Naidun 48v3 kW inverter

- How to pair the inverter with lithium battery

- High quality factory price 7 5 kw inverter Factory

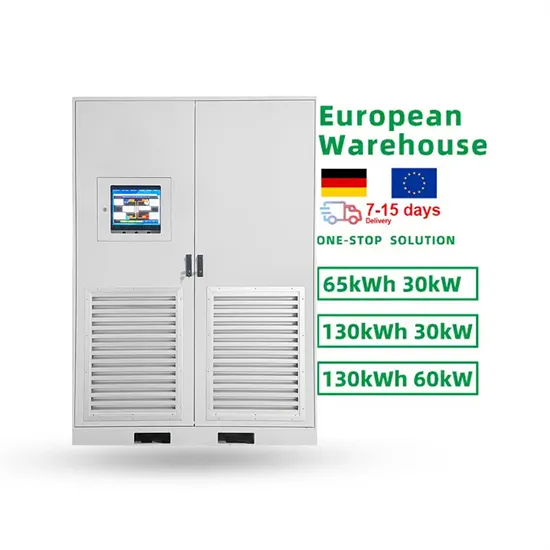

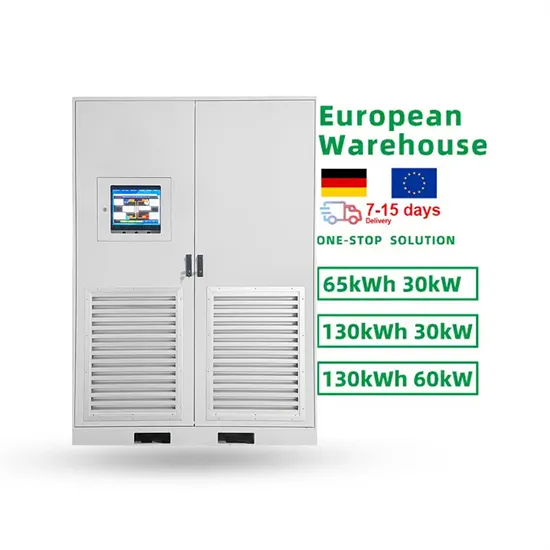

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.