Infrared imaging of photovoltaic modules: a review of the

Sep 14, 2022 · Abstract Thermography is a frequently used and appreciated method to detect underperforming Photovoltaic modules in solar power stations. With the review, we give

Photovoltaic power station inspection and pre

Sep 29, 2022 · Lightning protection detection is to ensure the long-term effective and reliable operation of all devices in the photovoltaic area of the power

Failures of Photovoltaic modules and their Detection: A Review

May 1, 2022 · The production of PV power stations and payback of initial investments are primarily dependent upon performance and lifetime of PV modules. The increase in lifetime

Path planning strategy of UAV inspection of large-scale photovoltaic

The widespread application of unmanned aerial vehicle(UAV)inspection technology effectively reduces inspection costs and improves inspection efficiency. To address the inspection

Part 2 – Inspection, Test and Commissioning Report

Sep 21, 2024 · Design, construction, inspection and testing I/we, the responsible person(s) for the design, construction, inspection and testing of the electrical system (as specified by the

Application of UAV inspection in photovoltaic power station

Apr 13, 2024 · With the continuous growth of global photovoltaic installed capacity, photovoltaic power stations are spread all over the world, and their wide distribution is remarkable. How to

Inspection Services for Solar Power Plants | Insperla

Solar (Photovoltaic) power plant inspections review the entire plant design to ensure functionality and reduce risks, by reviewing standards and contracts, based on extensive experience. Solar

In-Service Inspection for Photovoltaic PV Power Plants

In-service inspections help to implement regular checks of PV power plant status, operational availability and reliability. They assist owners, operators and investors to optimise shutdown

Best Practices for Operation and Maintenance of

Apr 26, 2019 · National Renewable Energy Laboratory, Sandia National Laboratory, SunSpec Alliance, and the SunShot National Laboratory Multiyear Partnership (SuNLaMP) PV O&M

Best Practices in Photovoltaic System Operations and

Mar 17, 2025 · Best Practices in Photovoltaic System Operation and Maintenance 2ndEdition NREL/Sandia/Sunspec Alliance SuNLaMP PV O&M Working Group This work was sponsored

Full Life Cycle Inspection of Photovoltaic Power Station-NOA

Through online monitoring of the operation of photovoltaic power station equipment, timely analyze and handle the fault symptoms, determine the cause and location of the equipment

Inspection and condition monitoring of large-scale photovoltaic power

Jun 1, 2022 · UV-Fluorescence, electroluminescence and photoluminescence imaging identify faults. The massive growth of PV farms, both in number and size, has motivated new

Solar panel inspection techniques and prospects

Mar 15, 2023 · Therefore, effective inspection of PV plants under various environmental conditions remain one of the major goals of electrical power utilities companies. In most of the cases, PV

A methodology for an optimal design of ground-mounted photovoltaic

May 15, 2022 · A methodology for estimating the optimal distribution of photovoltaic modules with a fixed tilt angle in ground-mounted photovoltaic power plants has

A METHOD FOR DETECTING PHOTOVOLTAIC PANEL

May 9, 2024 · ABSTRACT: Photovoltaic power stations utilizing solar energy, have grown in scale, resulting in an increase in operational maintenance requirements. Efficient inspection of

HANDBOOK ON DESIGN, OPERATION AND

May 29, 2024 · This Handbook covers "General Practice" and "Best Practice" associated with solar PV system installation and maintenance. "General Practice" refers to general

What is Solar PV Inspection? Importance & Methods

A solar PV inspection is a process that leverages several possible techniques to evaluate the current state of every solar photovoltaic (PV) panel. Other types of inspections have a different

Technical audits of solar power plants | AVENSTON

Services for technical inspection of a solar power plant Avenston carries out all types of technical and documentary audits, including planned, emergency and investment audits. With the help

Mapping national-scale photovoltaic power stations using a

Oct 15, 2024 · Although grid operators and solar farm owners have detailed information on PV installations, such as location, size, capacity, and power generation, these data are not public

Module defect detection and diagnosis for intelligent

Jun 15, 2024 · The energy production efficiency of photovoltaic (PV) systems can be degraded due to the complicated operating environment. Given the huge installed capacity of large-scale

Review of unmanned ground vehicles for PV plant inspection

May 1, 2025 · The growth of utility-scale solar power plants, which can now have more than a million PV modules, has created the need for automated monitoring and inspection

Fault diagnosis of photovoltaic modules: A review

Jun 1, 2025 · The fault diagnosis technology of photovoltaic (PV) components is very important to ensure the stable operation of PV power station. The application of intelligent fault detection

Intelligent robot inspection system for photovoltaic power station

Sep 26, 2021 · This paper aims at the inspection problems faced by photovoltaic power plants in the long-term operation of photovoltaic power plants in harsh environments such

Testing and inspection of photovoltaic plants

For this reason, verification and inspection services in solar photovoltaic plants are essential to ensure the quality of the modules and check their performance. This is especially relevant

6 FAQs about [Solar Photovoltaic Power Station Inspection]

What is a solar inspection?

Solar inspection includes those aspects 1. Why pass a solar inspection? Various regions and countries have certain installation specifications for solar energy installation systems, especially for some solar panel systems that are integrated into the power grid.

When should solar panels be inspected?

Here are the recommended times for solar inspections: 1. Pre-Installation Inspection Before the installation of solar panels, a thorough inspection should be conducted to assess the site suitability, roof condition, and electrical infrastructure.

What is a solar performance inspection?

Performance inspections focus on evaluating the actual energy production of the solar system. Through monitoring and analysis of energy output, performance inspections can identify any efficiency losses, underperforming components, or deviations from expected performance levels. 3. Infrared Inspections

Can imaging technology be used to analyze faults in photovoltaic (PV) modules?

The massive growth of PV farms, both in number and size, has motivated new approaches in inspection system design and monitoring. This paper presents a review of imaging technologies and methods for analysis and characterization of faults in photovoltaic (PV) modules.

What happens during an onsite solar inspection?

During an onsite solar inspection, systems are evaluated for installation quality, equipment compatibility and compliance to building codes, and ensuring the system was installed as it was permitted. In some parts of the country, a licensed electrician is required to be present during an electrical inspection.

Do you need a solar inspection?

Whether you are an installer, PV designer, or a renewable energy advocate of any kind, then you are probably well aware of the vigorous solar inspection process for distributed energy resources. Once the installation is complete, you can’t just flip a switch and start generating power.

Learn More

- Communication base station low voltage distribution cabinet GGD solar photovoltaic power plant

- Construction of solar photovoltaic power station for communication base station

- Photovoltaic solar energy to supplement container ESS power base station

- Solar power generation home photovoltaic system

- Reykjavik photovoltaic and wind power station energy storage ratio

- Islamabad Photovoltaic Power Station Inverter

- 100kw photovoltaic power station generator

- 5g base station power supply inspection

- Latest solar panels photovoltaic power generation

Industrial & Commercial Energy Storage Market Growth

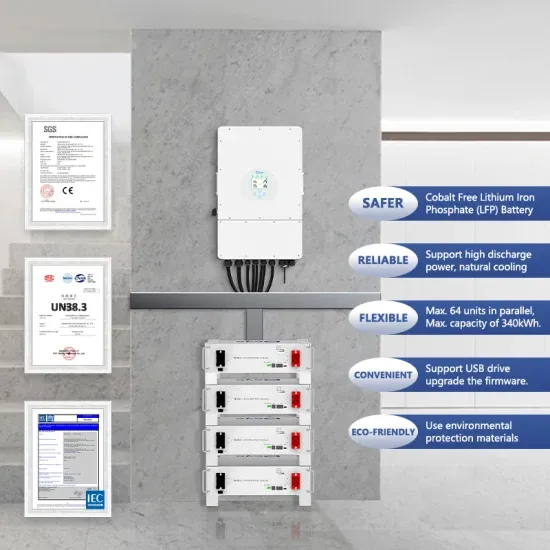

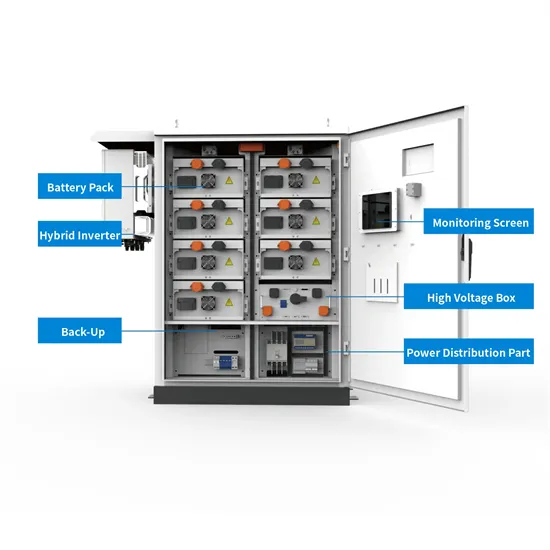

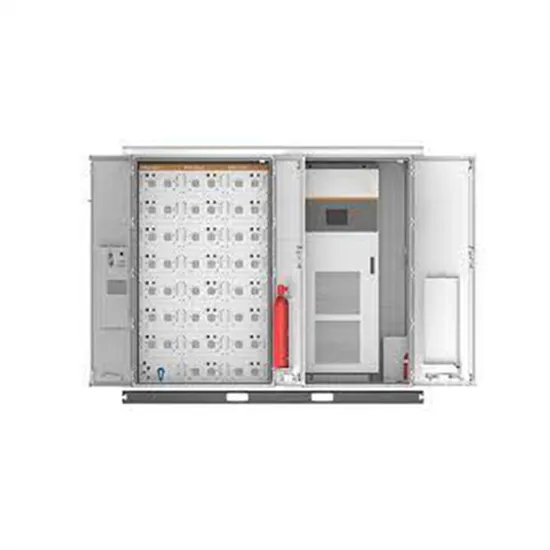

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.