MV Metal clad switchgears 12kV 2500A 25kA

2 days ago · Description The ambitious project has been destined to a cement factory in Santa Cruz de la Sierra, in Andrés Ibáñez, the largest city in Bolivia.

Finland Switchgear manufacturers | Electrical companies

The core technology of Elephantech is the Pure Additive™️ method, a novel and sustainable manufacturing method utilizing metal inkjet printing technology, which is applicable to various

Production facilities | VEO Finnish factory & FAT

2 days ago · Today VEO''s production is the largest switchgear manufacturer in the Nordics. Our facilities dedicated to automation system inspections and state-of-the-art Factory Acceptance

Technical Specification Metal-clad Switchgear

Mar 13, 2024 · Technical Specification Metal-clad Switchgear Technical Specification Metal-clad Switchgear This specification covers the basic design and functional requirements medium

Production facilities | VEO Finnish factory & FAT

2 days ago · VEO''s production facilities provide advanced industrial solutions, ensuring high-quality manufacturing, operational efficiency, and reliable performance.

Metal-Clad Switchgears Specification

Aug 11, 2025 · The metal-clad switchgear assembly shall be suitable for either solid grounding or high-resistance grounding as per local Hydro requirement and Contract Documents.

Learn More

- Cheap metal clad switchgear factory Buyer

- High quality metal clad switchgear factory manufacturer

- Factory price 225 amp breaker in Finland

- Factory price 480v switchgear in Cameroon

- Best generator switchgear for sale Factory

- Factory price real switchgear in Bahamas

- Factory price 33kv switchgear in Uruguay

- Factory price real switchgear in Honduras

- High quality factory price 33kv switchgear for sale

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

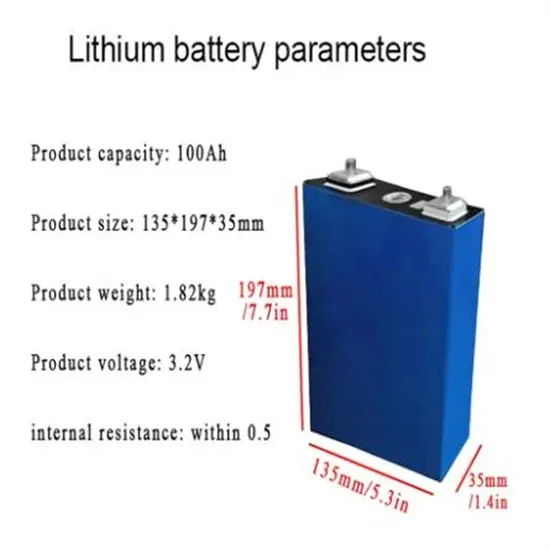

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.