Unplugging Uncertainty: Answering ''What is an

Jun 22, 2024 · A: An EV charging pile is a device that provides electrical power for charging electric vehicles, much like a conventional petroleum pump for

State Grid Zhenjiang Power Supply Company sets up a ''charging pile

May 23, 2025 · On May 20, at the charging pile application and installation site in a housing estate in Zhenjiang city, East China''s Jiangsu province, State Grid Zhenjiang Power Supply

What is a charging pile? How do charging piles charge?

What is a charging pile? Charging piles, as the name implies, are used to charge our electric vehicles. It acts like a tanker that fuels fuel cars at gas stations. The charging pile can be fixed

Research on Power Supply Charging Pile of

Jan 1, 2023 · 储能式充电桩是指在传统的充电桩箱内,按需要添加不同容量的储能电池。 由于在使 用充电桩进行充电. 电量,存在浪费时间等待后而充电桩单

Demand and supply gap analysis of Chinese new energy vehicle charging

Jan 1, 2024 · The sales of new energy vehicles (NEVs) and the construction of charging infrastructure promote and constrain each other. It is crucial for the development of the new

Research on Grid-Connected Photovoltaic Charging Piles

Apr 27, 2025 · Against the backdrop of increasing electric vehicle ownership and growing electricity demand for charging piles, grid-connected photovoltaic charging piles have emerged

China Professional EV Charging Pile Factory

Jun 1, 2025 · High-Power Electric Vehicle Fast DC Charging Pile This is a cutting-edge fast DC charging pile designed to rapidly replenish the batteries of electric vehicles (EVs). This state-of

Advantages and disadvantages of energy storage charging piles

Abstract: With the construction of the new power system, a large number of new elements such as distributed photovoltaic, energy storage, and charging piles are continuously connected to

Is it good to replenish water in energy storage charging piles

2025 Shanghai International Charging Pile and Battery Swapping Promote the development of the global automobile industry and help the interconnection of automobile charging piles and

Optimizing the configuration of electric vehicle charging piles

Dec 15, 2023 · The idea of charging demand prediction is to calculate the number of slow charging piles and fast charging piles that could meet for all EVs in each parking lot according

How to use the energy storage charging pile to replenish liquid

Dynamic load prediction of charging piles for energy storage Abstract. This paper puts forward the dynamic load prediction of charging piles of energy storage electric vehicles based on time

Understanding DC Charging Piles: Benefits

Dec 12, 2023 · When considering a DC charging system, choosing a reliable provider like Ruituo is paramount. Their high-quality DC charging piles offer optimal performance, safety features,

Advantages and disadvantages of energy storage charging piles

Optimized operation strategy for energy storage charging piles At the current stage, scholars have conducted extensive research on charging strategies for electric vehicles, exploring the

Outdoor power supply for electric charging piles

For an outdoor power supply with fast charging capabilities, consider the following options:Electric Fleet Fast Charger: Offers up to 180kW charging capacity with a user

WO/2023/202411 POWER MODULE, CHARGING PILE, AND POWER SUPPLY

Oct 4, 2023 · The present application provides a power module, a charging pile, and a power supply device. The power module comprises: a power supply input terminal, a first DC/DC

Common Types And Differences Of Charging Piles For New

Oct 14, 2023 · AC charging, also known as level 2 charging, is a power supply device that is fixed outside the electric vehicle and connected to the AC power grid, and the national standard

Portable Charging Piles

May 23, 2022 · Portable charging pile equipped with protection plate, lightweight and small volume, easy to carry, with a handle on the top and four universal wheels below, easy and

Outdoor power supply to charge energy storage charging pile

How does a charging pile work? The charging pile determines whether the power supply interface is fully connected with the charging pile by detecting the voltage of the detection point.

(PDF) Availability of Public Electric Vehicle

Aug 7, 2020 · This paper estimates the impact of the availability of public charging piles on electric vehicle sales using panel regression analysis. It then

Research and Design of an Intelligent Charging and Self

Oct 30, 2020 · This paper develops an intelligent, efficient, stable and reliable AC charging pile system. In order to achieve the goal of stability and reliability, the power supply uses a high

How do charging piles solve the problem of energy storage?

Jun 26, 2024 · Charging piles are one such innovative solution. By acting as both a charging station for electric vehicles and a storage medium, they can capture excess energy during

6 FAQs about [Charging pile to replenish power and move outdoor power supply]

What are energy storage charging piles?

By balancing the electrical grid load, utilizing cost-effective electricity for storage, and supporting renewable energy integration, energy storage charging piles enhance grid stability, charging economics, and environmental performance.

How does a DC charging pile work?

Installation also requires a professional electrician for wiring. DC charging piles are designed for fast charging of electric vehicles by converting the AC power from the grid into DC power and directly delivering it to the vehicle’s battery. This significantly shortens charging time.

What are the charging pile instructions?

Instructions for Charging Pile-V1.3.0: Power Output Mode: Can be switched between intelligent mode and priority mode. In intelligent mode, the charging pile power is equally distributed between the two vehicle connectors.

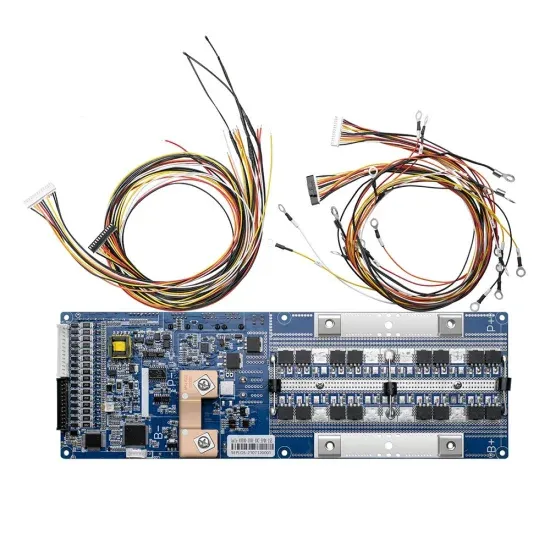

What is the main unit of a charging pile?

The main unit of the charging pile is the core control component, responsible for managing the operational state and output current of the charging pile. It typically includes a power module, control module, and communication module. The power module converts AC power into DC power for charging the vehicle.

What is a public charging pile?

Public charging piles are purchased by public service organizations such as government for use by any electric vehicle owner, such as public parking lots.

What is a charging pile connection wire?

Charging pile connection wires link the charging pile to the power supply lines, responsible for transmitting electrical energy from the power source to the main unit of the charging pile. These wires need to have sufficient conductivity and durability to handle certain current and voltage levels.

Learn More

- Charging pile to charge mobile outdoor power supply

- Solar charging panel connected to outdoor power supply

- Outdoor power charging pile conversion

- Fast charging outdoor power supply 1 kWh

- How much is the fast charging current of outdoor power supply

- Lithium iron phosphate outdoor power supply super fast charging

- A new generation of safe and fast charging outdoor power supply

- Outdoor power supply supports fast charging

- Outdoor power supply long-term charging and use

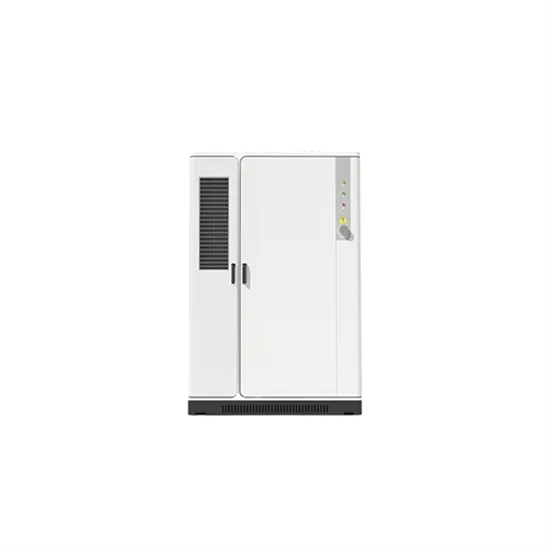

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.