Can You Use A 24v 36v Solar Panels To Charge A 12v

Mar 17, 2024 · But there is a little bit of investment and some electrical knowledge is needed before you install these solar chargers. The panels, chargers, battery, and inverters, all don''t

WZRELB 6000W 36V Pure Sine Inverter Review

Apr 6, 2025 · The included 16.6ft LCD remote panel lets you monitor and control the inverter from a distance, which is helpful if the inverter is mounted in a hard-to-reach spot. The WZRELB

Reduce 36V solar panel output to 12V

Dec 2, 2020 · I have a solar panel that has a 36V output. I''d like to be able to reduce it to 12V so it can be fed into a charge controller connected to a 12V deep cycle battery.

36v panel with 12v battery..... Help!

Apr 30, 2017 · There seem to be a lot of 12/24v MPPT controllers out there but I can''t seem to find anything of a decent price that can handle 36v input and 12v output. My question is, can I use

charging 36v from 12v

Aug 28, 2019 · Inverting in between is wasteful of energy, but some setups can afford that. That would work, and be quite a bit more efficient than an inverter/charger setup. Set it to output

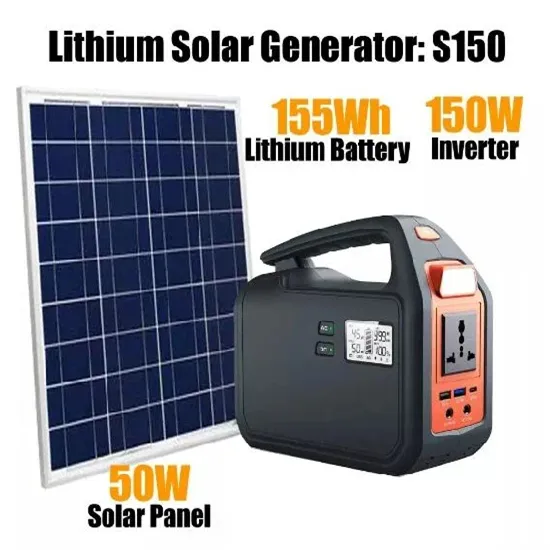

What size inverter to charge an ebike?

Apr 11, 2025 · To charge an e-bike, a 300–500-watt pure sine wave inverter is typically sufficient, accounting for charger efficiency (80–90%) and startup surges. Match the inverter''s output to

How to Change 36V to 12V Solar Cell

Now I can use the 12-volt inverter, which I found in the market. I opened the J-box that was in the back. I were really happy to find that it has 4 pins. Showing me that I have three sets of 12volt

matching a 300w 36v solar panel to my 12v battery and 12/24v inverter

May 22, 2014 · Not always as not all controllers can handle that high of a voltage on a 12 volt battery. With a Grid Tied which you have, you should be using a MPPT Controller. If you had

what to do with a 36volt battery bank????

Jun 24, 2023 · 20hr is the standard rating - sometimes referred to as C20, so those 6V cells are 305Ah. There are 36V inverters. They''re a little less common and a little more expensive.

36v panel with 12v battery..... Help!

Apr 30, 2017 · Hi there, So I''ve been given a 180w 36v solar panel and I would like to use it with a singular 12v battery..... There seem to be a lot of 12/24v MPPT controllers out there but I can''t

36V system questions

Feb 11, 2024 · I happen to have a Tripplite/Eaton aps3636vr heavy duty inverter/charger that does 36V and real 3600W output. My MPPTs are Victron 100/20s and 150/30s and will support 36V.

Suitable for Car Inverter 12V-36V to 36V 5A with Bluetooth

Suitable for Car Inverter 12V-36V to 36V 5A with Bluetooth Auto Switching Power Supply-JC Description Product name: FOR starlink mini car inverter 12V-36V to 36V with Bluetooth

12v to 36v 30a converter? | Endless Sphere DIY

Nov 23, 2011 · Let say, for arguments sake, that I happened upon a 12v 600AH Lifepo4 battery, that fully works and a 4000w inverter (both for free) and I want

12V Inverter vs 24V Inverter — What Is The

Dec 11, 2024 · This article will explore the differences between 12v inverter vs 24v inverter, considering factors such as energy loss, battery requirements, and

Inverter advice sought. 12 and 36 volt pure sine wave models.

Jan 18, 2022 · Hi all! New member here. I have a 36 volt ez go golf cart that I use around the ranch. Trojan batteries finally gave up the ghost so I installed a 36 volt gator max 5Kwh lifepo

Car Inverter for Mini 12V-36V to 36V 5A with on OnBuy

Car Inverter for Mini 12V-36V to 36V 5A with Description Product name: FOR mini car inverter 12V-36V to 36V with automatic switching power Product weight: single piece gross weight

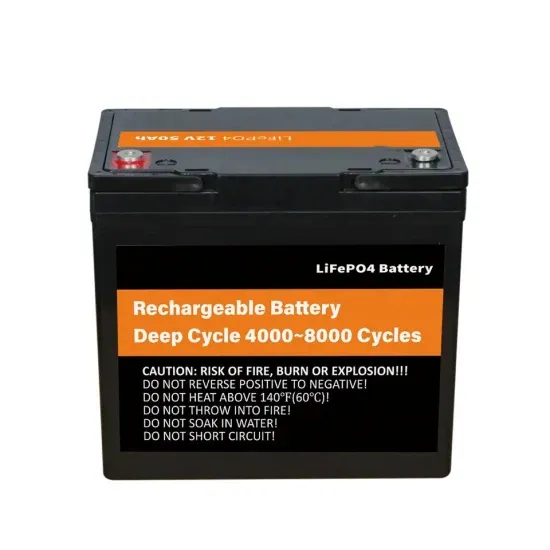

Step-by-Step Guide: How to Safely Wire 12V LiFePO4

Apr 22, 2025 · Upgrading your power system to 24V or 36V doesn''t require buying new equipment. By wiring 12V LiFePO4 batteries in series, you can achieve higher voltage for

12V vs 24V Inverters Key Differences and Which

Jan 21, 2025 · A 12V inverter is typically more suitable for smaller setups, while a 24V inverter offers enhanced efficiency and is ideal for larger applications.

Batteries and inverter question

Oct 19, 2018 · Page 1 of 2 1 2 > > > Batteries and inverter question « Previous Thread | Top | Next Thread » Similar Threads Thread Forum 96 fairway villager inverter Gas Club Car How bigs

6 FAQs about [Can 36v use 12v inverter]

What is a good 36 volt inverter?

WZELB makes a 2,000 and 5,000W, 36-volt inverter. It comes with cables, a replacement fuse, and numerous safety features, such as overload, overvoltage, short circuit shutdowns, etc. This inverter is flexible and easy to use, with 2xAC outlets, a digital display, and a terminal block for hard wiring. WZELB makes a very good 36-volt inverter.

Do I need a 24 volt inverter?

Of course, you will need a 24 volt inverter (rather than a 12 volt inverter). Actually, you will barely be able to adequately charge one battery with a 300 watt panel. If you want to increase your battery bank, you will need more panels and a MPPT controller that can handle 50 amps.

How many watts is a 36V panel?

So, for example, let's say you put two 18V 100W panels in series, which will give you ~5.5A at 36V. You could then wire one 36V panel parallel to the string of two 18volters because they are both putting out the same voltage. How many watts is that 36V panel? Let's say for example that it is a 300W panel putting out 8.33A at 36V.

Can I replace 18V panels with 36V panels?

The panels will deliver 36v ". This suggests to me that you could either be removing the 18V panels and replacing them with an unknown number of 36V panels, or alternatively adding new 36V panels along side the original panels. Both are still doable, but with caveats mentioned above.

How many watts can a 36V controller charge?

So, your two parallel strings would be 5.5A at 36V and 8.33A at 36V, for a total of 13.83A at 36V. That is equal to 498W of panels total. 498W/13V charging = 38.3A. So, that combination would be OK for your controller, because the max amperage is less than 40. Now, what if you have three 18V panels?

What type of inverter do I Need?

Also, keep in mind A 24-volt, 36-volt, or 48-volt inverter is a good choice for equipment using over 3,000 watts. You can use regular or flexible connectors to connect the inverter to the battery bank, but remember that the thinner the wire, the higher the resistance.

Learn More

- Can the inverter use 12v AC

- Minimum inverter for home use 12v to 220v

- How big an inverter can I use for a 12V 100Ah battery

- Inverter 12V to 36V self-operated

- How much capacity should a 12v battery inverter use

- 12v DC to 220v AC inverter

- Outdoor solar inverter 12v to 220v

- Sine wave inverter 12v price

- 12v to 220v inverter input current

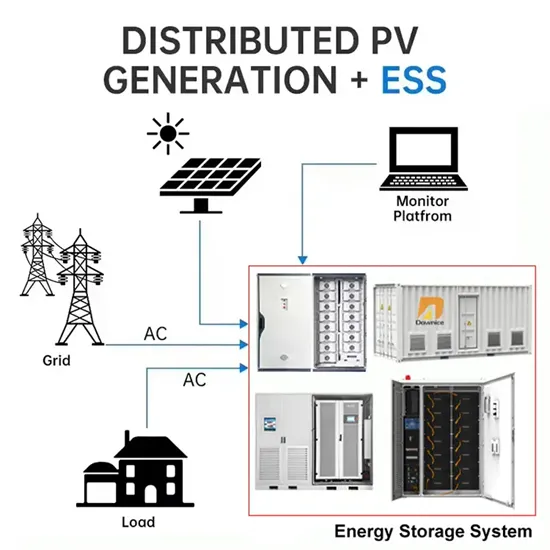

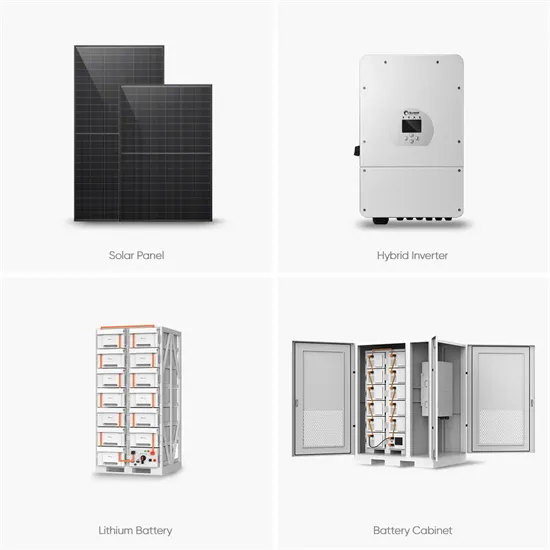

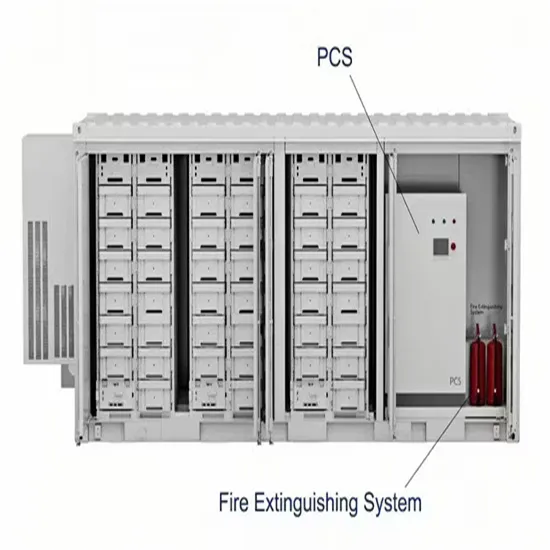

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

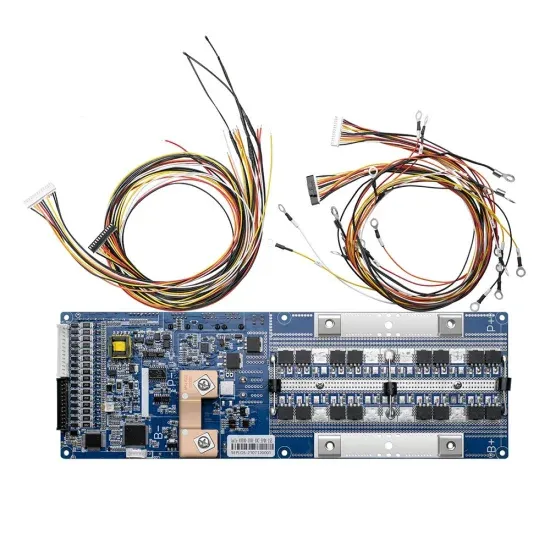

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.