Assessing the environmental impacts associated with China''s battery

Jan 1, 2025 · Results show that particulate pollution from nickel, cobalt, and manganese production exceeds CO 2 emissions, whereas the reverse is true for other battery materials.

Environmental impact of emerging contaminants from battery waste

Jun 1, 2021 · The full impact of novel battery compounds on the environment is still uncertain and could cause further hindrances in recycling and containment efforts. Currently, only a handful

The Dark Side Of Batteries: Pollution Generated | ShunWaste

Jun 22, 2025 · The Dark Side of Batteries: Pollution Generated. Learn about the environmental impact of battery production and disposal, and explore sustainable alternatives to reduce

The Dark Side Of Batteries: Environmental Pollution

Jun 7, 2025 · Batteries are essential to modern life, from powering our phones and laptops to electric vehicles (EVs). However, the environmental impact of batteries is a growing concern.

Study on performance effects for battery energy storage

Feb 1, 2025 · First, thermal performance indicators are used to evaluate the temperature field and velocity field of the battery energy storage cabinet under different air outlet configurations. It

The Dark Side Of Lithium-Ion Batteries: Pollution In

Jul 13, 2025 · The environmental impact of lithium-ion battery production is a highly debated topic. While electric vehicles are emission-free, the manufacturing of lithium-ion batteries can emit up

The Dark Side Of Lithium Batteries: Pollution''s Impact

Jun 22, 2025 · The world is moving towards reducing greenhouse gas emissions and dependency on fossil fuels, and lithium batteries are pivotal to this transition. They enable the shift to

What are the main environmental challenges associated with battery

Feb 13, 2025 · Pollution from Production: Battery production releases pollution and carbon emissions, contributing to ecological degradation beyond just carbon footprint. 3. End-of-Life

Assessing the environmental impacts associated with China''s battery

Jan 1, 2025 · This study assesses China''s battery materials and technologies'' environmental impacts. Results show that particulate pollution from nickel, cobalt, and manganese production

The Environmental Impact of Lithium-Ion Battery

Mar 11, 2025 · Lithium-ion batteries are central to the modern energy landscape, powering everything from portable electronics to electric vehicles. However,

Lithium-Ion Battery Critical Materials Sustainability

Apr 30, 2025 · Global electric (1) vehicle (EV) sales are projected to reach 38 million annually by 2030, accounting for 33% of total light vehicle sales, which intensifies pressure on the supply

The Dark Side Of Lithium-Ion Batteries: Pollution In

Jul 13, 2025 · Yes, the manufacturing of lithium-ion batteries can create pollution. The process can emit high levels of CO2 and toxic fumes, and contribute to water pollution. Mining and

5 Environmental Impacts of Battery Manufacturing

Modern technology relies heavily on batteries, which power everything from laptops and cellphones to electric cars (EVs) and renewable energy storage devices. It is impossible to

Battery Room Ventilation and Safety

Mar 15, 2023 · The former is much lighter than the air and would accumulate in the air space above the electrolyte solution inside the battery. These gases may also leak through the

The Dark Side Of Batteries: Pollution And Environmental

Mar 27, 2025 · The pollution caused by mining and manufacturing batteries is not limited to the production stage but extends to the disposal and recycling of batteries. While lead-acid

Battery Production''s Pollution Problem | ShunWaste

Jun 28, 2025 · The extraction and processing of raw materials, such as lithium, nickel, and cobalt, contribute to water pollution, soil pollution, and the release of toxic chemicals and greenhouse

What Are the Environmental Impacts of Battery Production

Mar 3, 2025 · Air and water pollution are major concerns during battery production. Mining and refining processes release particulate matter and hazardous chemicals into the air,

Lithium Battery Production: Environmental Impact And Pollution

May 29, 2025 · The production of lithium batteries has been a topic of debate due to its environmental impact. While electric vehicles are emission-free, the manufacturing process of

Direct emissions to air, water and soil from a

May 24, 2025 · In this study we investigate the direct emissions of a state-of-the-art battery gigafactory in Germany. We show that in a typical, state-of-the-art

6 FAQs about [Battery cabinet production pollution]

How does battery manufacturing affect the environment?

The manufacturing process begins with building the chassis using a combination of aluminium and steel; emissions from smelting these remain the same in both ICE and EV. However, the environmental impact of battery production begins to change when we consider the manufacturing process of the battery in the latter type.

What are the environmental factors affecting battery technology?

Overall, battery technologies associated with nickel, cobalt, and manganese exhibit the most significant environmental factor in terms of particulate pollution. Sodium-ion and solid-state battery technologies require particular attention due to their CO 2 emissions.

Are batteries harmful to the environment?

For batteries, a number of pollutive agents has been already identified on consolidated manufacturing trends, including lead, cadmium, lithium, and other heavy metals. Moreover, the emerging materials used in battery assembly may pose new concerns on environmental safety as the reports on their toxic effects remain ambiguous.

What is the environmental impact of ternary batteries?

In ternary batteries, Nickel (Ni) has a greater environmental impact compared to Cobalt, and the proportion of environmental impact attributed to nickel in ternary batteries is proportional to the proportion of nickel. For example, in NMC-111, the environmental impact score and the proportion of nickel are 4.60 and 66 %, respectively.

Are China's battery materials and technologies harmful to the environment?

This study assesses China's battery materials and technologies’ environmental impacts. Results show that particulate pollution from nickel, cobalt, and manganese production exceeds CO 2 emissions, whereas the reverse is true for other battery materials.

Are new battery compounds affecting the environment?

The full impact of novel battery compounds on the environment is still uncertain and could cause further hindrances in recycling and containment efforts. Currently, only a handful of countries are able to recycle mass-produced lithium batteries, accounting for only 5% of the total waste of the total more than 345,000 tons in 2018.

Learn More

- Energy storage battery cabinet photovoltaic production enterprise

- Fixed energy storage battery cabinet photovoltaic production

- Site Energy Battery Cabinet Production Integrated System

- Battery cabinet frame production integrated system

- Israel UPS battery cabinet full set production direct sales

- Energy storage cabinet battery production in Thailand

- Energy storage cabinet battery production and assembly equipment

- How to calculate the production cost of battery cabinet

- Battery cabinet outdoor site production and processing

Industrial & Commercial Energy Storage Market Growth

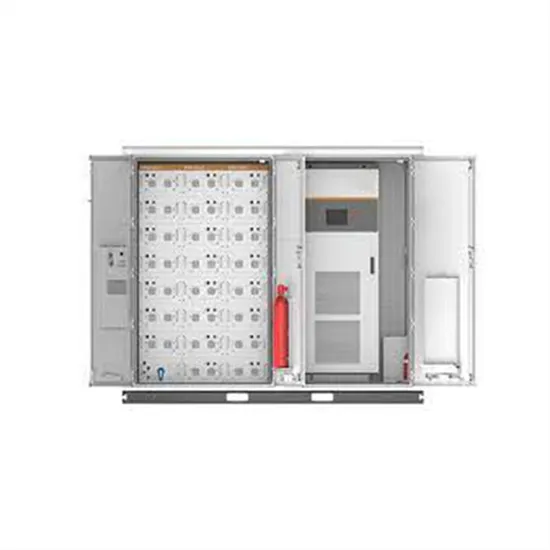

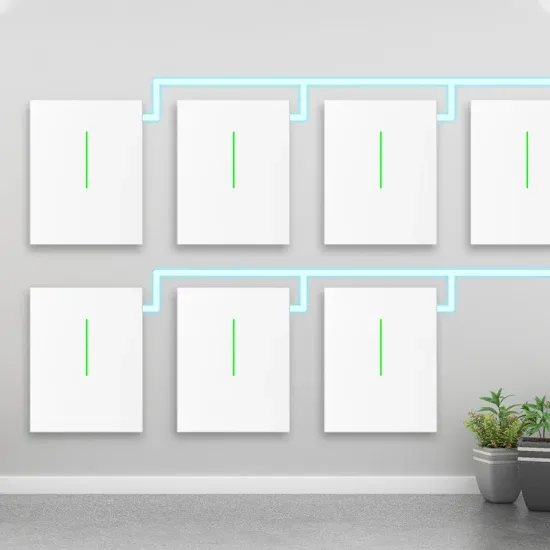

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.