Energy Storage is More Than Just Batteries! Let Talk About

Jan 23, 2025 · BMS, EMS, and PCS, as core components of the energy storage system, are crucial to the safe and efficient operation of the entire system. Hongzheng Energy Storage,

The "3S" interpretation in industrial and commercial energy storage system

Jul 15, 2025 · 03 PCS PCS is the energy storage converter, which is the core component to realize the bidirectional flow of electric energy between the energy storage system and the

Energy Storage Science Popularization (2)—"3S System"

Jun 6, 2025 · The so-called "3S System" refers to the core components of an energy storage system: the Power Conversion System (PCS), Battery Management System (BMS), and

"秦"你聊储能-一文详解工商业储能3S系统-智慧储能行业技术

Sep 24, 2024 · 完整的电化学储能系统主要由电池组、电池管理系统(BMS)、能量管理系统(EMS)、储能变流器(PCS)以及其他电气设备构成。 今天讲讲储能系统中大家经常听到

What are the 3s energy storage systems

What are the different types of energy storage systems? It can be stored easily for long periods of time. It can be easily converted into and from other energy forms . Three forms of MESs are

储能科普(二)"3S系统"详细介绍-光伏系统解决方案

Jan 10, 2025 · 所谓"3S系统"指的就是储能系统中核心的几个部件:储能变流器(PCS)、电池管理系统(BMS)和能量管理系统(EMS)。 储能"3S系统"的运行逻辑是:电池组将状态信息

Understanding the "3S System" in Energy Storage: BMS,

Apr 28, 2025 · Discover how the "3S System" — BMS, EMS, and PCS — powers modern Energy Storage solutions. Learn their roles, interactions, and why they are crucial for safe and efficient

Energy Storage is More Than Just Batteries! Let Talk About

Jan 16, 2025 · Discover the crucial role of the 3S system in energy storage, including EMS, BMS, and PCS, in ensuring safe, efficient, and reliable energy management for a sustainable future.

6 FAQs about [3s Energy Storage System]

What is a 3s energy storage system?

In the world of Energy Storage, the "3S System" refers to the three core components: the Battery Management System (BMS), the Energy Management System (EMS), and the Power Conversion System (PCS). These three systems work in perfect synergy to ensure the safety, stability, and efficiency of energy storage operations.

What are energy storage systems?

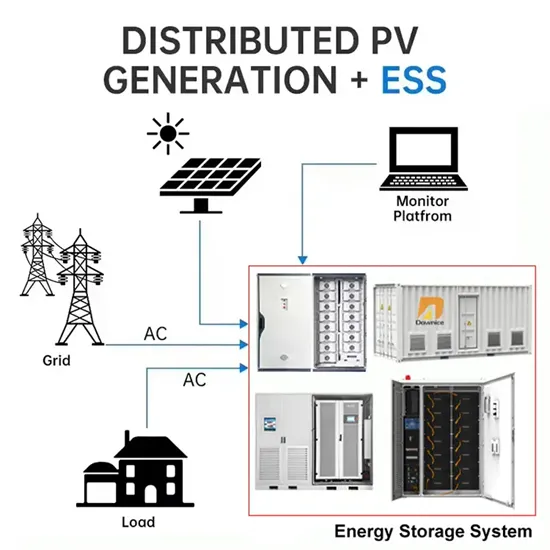

TORAGE SYSTEMS 1.1 IntroductionEnergy Storage Systems (“ESS”) is a group of systems put together that can store and elease energy as and when required. It is essential in enabling the energy transition to a more sustainable energy mix by incorporating more renewable energy sources that are intermittent

What is the ESS Handbook for energy storage systems?

andbook for Energy Storage Systems. This handbook outlines various applications for ESS in Singapore, with a focus on Battery ESS (“BESS”) being the dominant techno ogy for Singapore in the near term. It also serves as a comprehensive guide for those wh

What is battery ESS?

Y STORAGE SYSTEMS2.1 IntroductionBattery ESS (“BESS”) is an electrochemical ESS where stored chemical energy can be converted to electrical energy when required. It is usually deployed in modularised container and has less geographical restrictions

What is Energy Management System (EMS)?

EMS (Energy Management System) The Energy Management System (EMS) is the brain of the energy storage system. It integrates hardware and software to monitor, control, analyze, and optimize system operations. EMS System Structure: Interfaces with PCS, BMS, and other sensors. Manages data protocols, links, and transmissions.

What is a Bess energy management system?

pical BESSEnergy Management Systemgeneration through a heat exchanger (e.g. air-cooling or liquid-cooling) to keep the temperature of the battery within the opt mum limits and prevent overheating.The EMS monitors, controls and optimises the overall power flow and distribution of the BESS b

Learn More

- Photovoltaic energy storage 3s

- 3s Energy Storage System

- Does the energy storage power station also need to be connected to the power grid

- Maseru Energy Storage Container Production Plant

- Photovoltaic energy storage enterprise operation

- Emergency generator can use energy storage station

- Which Bern container energy storage cabinet is the best

- Energy storage solar panels

- Which battery energy storage system is best in China and Africa

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.