Isolated power supplies favor push-pull conversion

Jan 9, 2013 · Ease-of-use, low-noise, small size, and inexpensive development make push-pull converters the preferred solution for modern, isolated power supply designs. The freedom to

Two simple isolated power options for 8 W or less

Feb 21, 2024 · In this power tip, I''d like to present two approaches that both reduce design complexity and noise coupling in isolated bias supplies. One approach, useful for multiple

Switch Mode Power Supply (SMPS) Topologies

Jun 1, 2011 · The push-pull topology is most favorable for low-voltage applications such as US regulation 110 VAC input direct off-line SMPS, or low input voltage DC-DC isolated converter

How to Reduce Emissions in Push-Pull Isolated Power

Apr 1, 2023 · Isolated power is traditionally generated using a DC/DC converter to drive a transformer in flyback, fly-buck or push-pull topologies, where pulsating signals on the

How to prevent transformer saturation in push-pull

Jun 21, 2021 · The push-pull converter has emerged as a popular topol-ogy to create isolated power supplies in the 1-W to 10-W range. This topology is pairable with digital isolators,

Optimize 24-V Isolated Power Supply Designs in PLC I/O

Dec 22, 2023 · TI''s SN6507 push-pull isolation transformer driver enables high power delivery of up to 500 mA with 36-V inputs and is optimal for PLC applications due to the inherent high

China Aluminium Alloy Metal Push Button Switch box

Aluminium Alloy Metal Push Button Switch box on sale manufacturers, find details about Aluminium Alloy Metal Push Button Switch box manufacturers, supplier and wholesaler -

Isolated Supply Overview and Design Trade-Offs

Apr 1, 2023 · For power levels over and above the limitations of fl yback, forward, and active-clamp forward converters, push-pull and half-bridge converters should be considered.

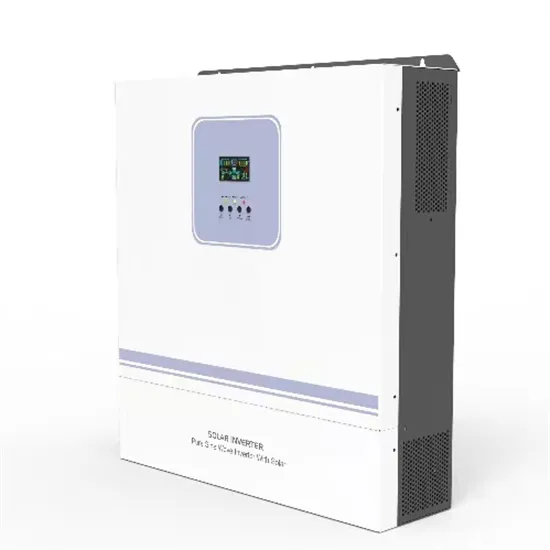

Push-pull box outdoor power supply

Push-pull power supplies are inherently low-noise and low-EMI due to their symmetric topologies. The two identical low-side switches, the center-tapped transformer, and full-bridge rectifier

Two simple isolated power options for 8 W or less

Feb 21, 2024 · A variety of industrial and automotive systems use isolated bias supplies. Most existing approaches using flyback or push-pull converters for isolated bias power (see the

Push‐pull converter simplifies isolated power supply in

Aug 24, 2020 · Of the various power topologies available for power isolation, the push-pull converter has some advantages that make this topology particularly attractive for automo-tive

Isolated IGBT Gate-Drive Push-Pull Power Supply with 4

Jun 20, 2016 · This reference design also takes advantage of another benefit of the push-pull topology in that multiple transformers can be controlled in parallel from a single controller to

Dual 15-V, 120-mA Iso. Bias Power Supply Ref. Des.

May 11, 2022 · Using Buck & Push-Pull Conv. This isolated power supply provides dual +15-V outputs at 120 mA each. This power supply is designed for biasing a MOSFET-based power

Isolated Bias Power Supply Reference Designs Using

Feb 13, 2024 · Description This reference design features four isolated bias power supply designs using different topologies such as PSR flyback, push-pull, LLC resonant, and isolated DCDC

Push-Pull Converter: Advantages and Disadvantages

Advantages of Push-Pull Converters Here are the benefits of using a Push-Pull converter: No Isolated Power Supply Needed for MOSFETs: Driving MOSFETs in a Push-Pull configuration

Optimize 24-V Isolated Power Supply Designs in PLC I/O

Dec 22, 2023 · Push-pull power supplies are inherently low-noise and low-EMI due to their symmetric topologies. The two identical low-side switches, the center-tapped transformer, and

Switching Power Supply Design, Third Edition

Sep 26, 2023 · Keith presents the late Abe Pressmanÿs four-day course on power supply design (now converted to a Power Point presentation) and also a one-day course of his own on

Delta Electrical Boxes – Delta Cable Trays

A pull box is a critical component in electrical conduit systems, designed to provide access points for pulling, feeding, and maintaining conductors over long distances. Unlike junction boxes,

M12 push-pull distributor boxes | Phoenix Contact

The M12 push-pull distributor boxes feature a consistent, tool-free, and intuitive installation. Master cables and M12 connectors are connected conveniently and safely by direct connection.

High-Efficiency Push–Pull Resonant Converter Solution for Auxiliary

May 10, 2021 · This article presented a high-efficiency push–pull resonant converter solution for auxiliary power supply in 70-kV isolated applications. This power supply cons

SWITCHING POWER SUPPLY DESIGN: LM5030 PUSH

May 13, 2020 · The operating frequency of the power supply should be selected to obtain the best balance between switching losses, total transformer losses, size and cost of magnetic

Switch Mode Power Supply (SMPS) Topologies

Jun 1, 2011 · A push-pull transformer requires a center tapped primary, and each winding is active only for alternate power pulses, which means only 50% utilization of primary copper.

6 FAQs about [Push-pull box outdoor power supply]

What is a push-pull power supply?

The push-pull is a very attractive choice for telephone industry power supplies where the maximum DC input voltage is specified as only 38–60 V. Having it in its current-mode version with a certainty that flux imbalance cannot exist is very valuable.

What are the advantages of a push-pull converter?

Of the various power topologies available for power isolation, the push-pull converter has some advantages that make this topology particularly attractive for automo-tive applications. This article explores a few salient features of the push-pull topology and explains its perfor-mance and design benefits.

What is a dual 15 volt power supply?

Dual 15-V, 120-mA Iso. Bias Power Supply Ref. Des. Using Buck & Push-Pull Conv. This isolated power supply provides dual +15-V outputs at 120 mA each. This power supply is designed for biasing a MOSFET-based power stage that generates excitation for a separately excited synchronous motor (SSM).

What is a push-pull converter?

The push-pull topology is thus a very simple one, requir-ing only rectifier diodes and bypass capacitors in addition to the transformer and power switches, and no additional design verification for loop stabilization. The push-pull converter uses transformer action to trans-fer the load from the secondary to the primary.

Can push-pull converters be used in traction inverters?

Also discussed is the use of push-pull converters to provide the bias voltage for isolated insulated gate bipolar transistor (IGBT) gate drivers in traction inverters, for which this topology is particularly a good fit. Figure 1. Isolated power supplies used in automotive systems Sensors (V,T,I %..) Position Sensing

How does a push-pull work?

It is just a matter of convention rather than a basic difference in power ratings. In the push-pull case, each positive and negative half cycle produces an output pulse resulting in two pulses per cycle (pulse frequency doubling). So simply producing two pulses from the single-ended topology in the same time period results in the same output.

Learn More

- Outdoor ip65 photovoltaic combiner box power supply

- Solar Box Outdoor Power Supply

- Can the capacity of outdoor power supply be measured

- Outdoor power supply becomes a must-have for safety and emergency

- Thermos bottle portable outdoor power supply

- 90w outdoor power supply

- The lightest 5 kWh outdoor power supply

- The most reliable outdoor power supply

- Personalized customization of outdoor power supply

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.