Inverter motor Electric Control Box, Mcc electric control panel

Inverter Motor Electric Control Box,Mcc Electric Control Panel, Find Complete Details about Inverter Motor Electric Control Box,Mcc Electric Control Panel,Mcc Painel De Controle from

Chziri Mcc Panels Using Sewage Treatment Plant

Chziri Mcc Panels Using Sewage Treatment Plant manufactures, Source China high quality and best price Inverter Cabinet, Mcc Panel, Inverter Switchgear Manufacturers - WENZHOU ZIRI

What is a Motor Control Center (MCC)? Types, Components

Jul 14, 2025 · A Motor Control Center (MCC) is a centralized system made up of one or more enclosed units designed to efficiently control, monitor, and protect electric motors.

Motor control center (MCC) | DACE Price Booklet

3 days ago · Prices are strongly dependant of the MCC specification, complexity of the circuit and the ratio between the amount of groups and the total of the installed capacity.

IEC Standard Guidelines for Motor Control Centres (MCCs)

May 30, 2025 · Motor Control Centres (MCCs) are critical components in industrial electrical systems. They provide centralized control and protection for electric motors.

コントロールセンタ | 製品情報 | 三菱電機FA

Mar 30, 2023 · 三菱電機FAサイトでは、コントロールセンタに関する最新情報・製品情報・技術資料・カタログなどの情報を掲載しています。

Mcc control panel electric plc control cabinet frequency Inverter

Aug 17, 2023 · Understand Mcc control panel electric plc control cabinet frequency Inverter cabinet information in Wenzhou Ziri Electric Technology Co.,Ltd company, and quickly obtain

6 FAQs about [MCC electric control room price inverter cabinet]

Who makes MCC cabinets & panels?

Contact us for more info about our mcc cabinets & panels. Logstrup make impactful power distribution cabinets for companies and projects in need of secure and reliable power. We are experts at making electrical motor control centers (MCC) that have advanced features, but at the same time are easy to use and upgrade.

What is a MCC enclosure?

Our MCC enclosures or modular custom cabinets are intentionally configured to maximize space utilization, create an orderly equipment arrangement in the control room, and increase operational efficiency. Additionally, we design them for easy installation and maintenance and to accommodate accessories of any type and size.

What is a KDM MCC motor control enclosure?

This KDM MCC motor control enclosure is ground mounted, with individual drawers or cabinets of over 50 per MCC control room. It is available in aluminum, galvanized, and stainless steel and is custom-made for multiple short and open circuits, depending on your requirements and facility needs.

How many compartments does A KDM MCC cabinet have?

You could order a custom-made set of up to 50 individual compartments, each with NEMA 3RX and IP67 standards for maximum protection against corrosion and harsh weather conditions. This KDM MCC cabinet (also called MCC switchgear enclosure) includes an assembly of electric motors with custom-sealed IP67 switchgear.

What is a KDM MCC panel box?

Also known as the KDM MCC panel box, this enclosure is fabricated in various NEMA-4 corrosion-resistant aluminum and steel materials. We provide the best sealings for their doors to prevent hard dust and water ingress. You can order them in custom designs, colors, sizes, dimensions, and overall specifications.

What is a logstrup MCC panel?

Logstrup’s Motor Control Center (or MCC) does control some or even all of the electric motors in a centralized location. The power can be distributed through Logstrup switchboards, transformers or panelboards which makes it highly reliable.

Learn More

- Photovoltaic power station inverter control cabinet

- Battery cabinet price for computer room

- Energy storage cabinet temperature control system price

- South Ossetia inverter cabinet manufacturer supply

- Huawei inverter size and price

- Cheap 5kw on grid inverter in China Price

- How much is the price of energy storage cabinet container in Uruguay

- What is the price of Ankara commercial energy storage cabinet factory

- Factory price hybrid inverter in Uae

Industrial & Commercial Energy Storage Market Growth

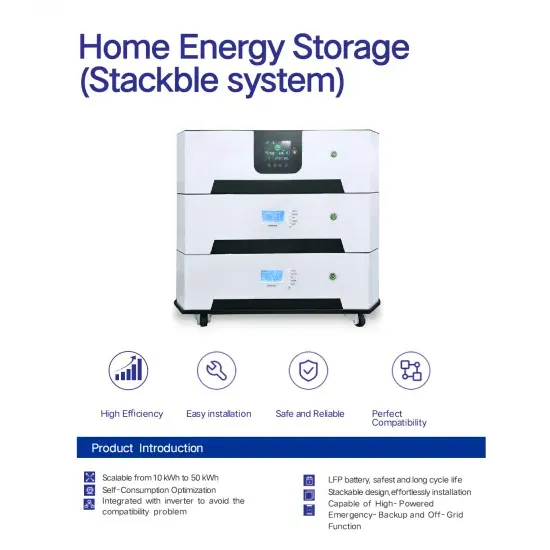

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

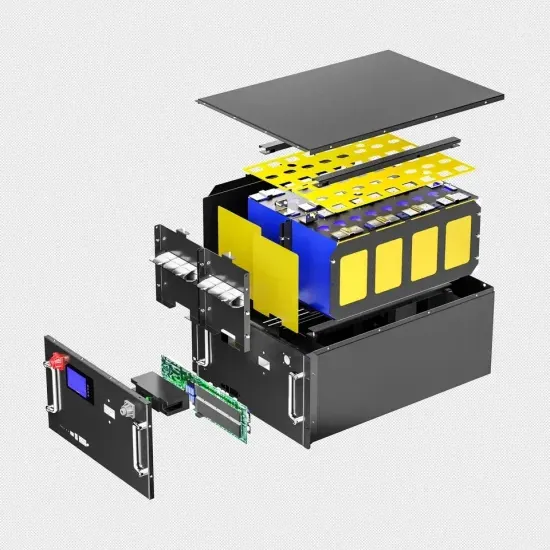

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.