How to Make 1.5V DC to 220V AC Inverter

This video gives you all the information you need to build your own 1.5v DC to 220v AC inverter. During the next steps however I will present you some additional information to make the

1.5v To 220v AC Simple Inverter Circuit

Aug 7, 2021 · When a designer needs to convert DC into AC power, there are several ways to make an inverter. So, we thought why not try making an inverter using a battery of 1.5 Volts?

1.5v to 220v AC simple inverter March 16, 2019 admin 0 this Project 1

Even this project can be make with scrap components present at your own home. Inverter circuit is used to convert the DC current to AC current. You can make this project with out any

1.5V To 220V Inverter..How To Make A 1.5V Battery To 220V AC Inverter

Friends in this video I will show you 1.5V To 220V Inverter..How To Make A Simple 1.5V Battery To 220V AC Inverter..Transistor Inverter.. Friends it is a simple circuit project and you can

on video How to make a 1.5 volt and 220 volt

Mar 2, 2023 · In this project, we have created a very simple inverter that can be used to power the 1 watt AC LED bulb, but its power can be increased if you

1.5V to 220V Inverter Circuit with Transformer

The simplest way to convert 1.5 volts DC to a 220 volts AC output is by using a step-up inverter circuit with a transformer and an oscillator. Start by selecting a suitable transformer with a 1.5

6 FAQs about [Simple inverter 1 5v to 220v]

How many components does a 220V AC simple inverter need?

Just, 1.5 volts and we can get 220V Ac at the output. So, maybe the question arises that the circuit then needs a lot of components to boost up the voltage. But, no! the circuit is so simple that it only needs four components. But how? To make this, let’s first understand this 220v AC Simple Inverter.

How much power does a 220 volt inverter draw?

This 3 V to 220 V inverter circuit may draws around 70 ma from the 3 V battery (B1). The inverter circuit seen above is built around a straightforward astable multivibrator, which pushes and pulls its output via the secondary of a center-tapped, 12-volt step down power transformer. The circuit is powered by 6 volts of DC from four AAA batteries.

How does a 3 V 220 V inverter work?

The next 3 V to 220 V inverter circuit is designed to work in a blocking oscillator mode having an operating frequency set at around 400 Hz. The transistor used can be any PNP power transistor. The center tap transformer can be any standard step down transformer. This transformer provides the feedback and the voltage boosting both together.

Why is a 220V inverter not used commercially?

When the battery is connected transistor generates the oscillations but, this transistor alone cannot make 220V. Therefore, the transformer is utilized to boost up the voltage. However, the power of this simple inverter is not so high. and, that’s why this circuit cannot be used commercially.

How many volts can a mini inverter produce?

All the designs employ a single PNP transistor and transformer, connected in the feedback mode for generating the oscillations. The mini inverter circuit demonstrated in the following figure can produce a highest AC output of 220 volts if it is powered through any battery between 1.5 V and 6 V battery.

How many volts can a 3 volt inverter drain?

The maximum drain from the battery at 1.5 V supply will be roughly around 100 ma. R1 will alter the DC output between 60 and 80 volts, in the absence of a load. The next 3 V to 220 V inverter circuit is designed to work in a blocking oscillator mode having an operating frequency set at around 400 Hz.

Learn More

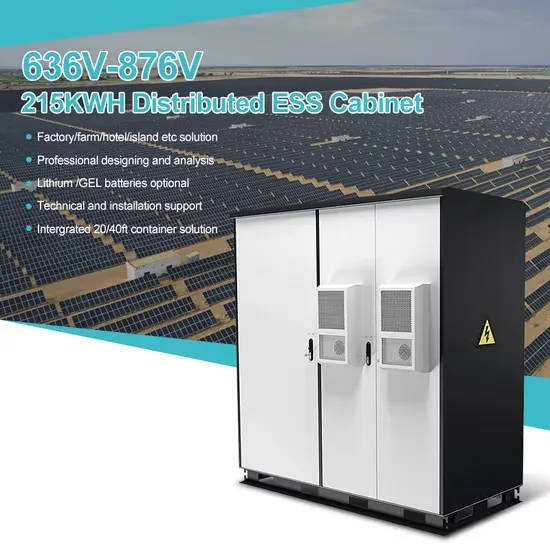

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.