A critical review on operating parameter monitoring/estimation, battery

Nov 15, 2024 · A critical review on operating parameter monitoring/estimation, battery management and control system for redox flow batteries

The Relationship between Shunt Currents and

Apr 4, 2017 · The fluid manifolds act as ionic short circuits between cells in the reactor stack. The shunt currents that flow through the manifolds continuously

The challenge of corrosion in next-generation rechargeable metal batteries

Aug 14, 2025 · This perspective revisits metal corrosion as a critical degradation pathway that has been both underappreciated and poorly understood yet fundamentally limits the calendar life of

Review of zinc-based hybrid flow batteries: From fundamentals

Jun 1, 2018 · Zinc-based hybrid flow batteries are one of the most promising systems for medium- to large-scale energy storage applications, with particular advantages in terms of cost, cell

Structural modification of vanadium redox flow battery with

Sep 15, 2019 · In this study, a modified battery structure for the vanadium redox flow battery is proposed to alleviate the oxidation corrosion of the bipolar plates and flow fields. The flow

Perspectives on zinc-based flow batteries

Jun 17, 2024 · In this perspective, we attempt to provide a comprehensive overview of battery components, cell stacks, and demonstration systems for zinc-based flow batteries. We begin

Current status and challenges for practical flowless Zn–Br batteries

Apr 1, 2022 · The fire hazard of lithium-ion batteries has influenced the development of more efficient and safer battery technology for energy storage systems (ESSs). A flowless

Corrosion: The Primary Threat to Battery Pack

Oct 8, 2022 · Corrosion in Battery Packs Understanding the cyclic corrosion processes that occur within a lithium-ion cell plays a critical role in the design

Thermal management of flow batteries-

Dec 3, 2024 · Since the charge in the electrolyte of the flow battery easily flows along the coolant to the entire system, it is more dangerous, so the choice of cooling medium is also very

Battery Point Corrosion: Can It Cause Low Power and Affect

Apr 4, 2025 · Corroded battery terminals can cause low power in your car. The corrosion restricts electrical current flow and hinders contact with the battery cables and posts. This issue can

The challenge of corrosion in next-generation rechargeable metal batteries

Aug 14, 2025 · Rechargeable metal-based batteries with the highest theoretical energy densities stand as highly promising candidates for next-generation energy storage devices. However,

The challenge of corrosion in next-generation

Aug 13, 2025 · Rechargeable metal-based batteries with the highest theoretical energy densities stand as highly promising candidates for next-generation energy storage devices. However,

Structural modification of vanadium redox flow battery with

May 23, 2019 · In the conventional vanadium redox flow battery, the bipolar plates are usually designed with flow fields to improve the battery performance by facilitating the homogeneous

Battery Corrosion: Causes, Effects, and How to Clean It

Jan 14, 2024 · Battery corrosion, also known as battery oxidation or rust, is a common issue that can affect the performance and lifespan of your battery. Over time, the terminals of your

Complete Guide to Advancing Flow-Battery Electrode Materials

Jul 25, 2025 · As the central component of any battery system, electrode materials directly determine energy efficiency, power density, and overall lifespan. Improving their performance

Aqueous iron-based redox flow batteries for large-scale

May 31, 2025 · ABSTRACT The rapid advancement of flow batteries offers a promising pathway to addressing global energy and environmental challenges. Among them, iron-based aqueous

electrochemical energy Storage

May 25, 2020 · A. Physical principles Flow batteries are rechargeable batteries which use two liquid electrolytes - one with a positive charged and one with a negative charged - as energy

Safety Considerations of the Vanadium Flow Battery

Jan 6, 2023 · Selected standards are reviewed, especially where they give explicit advice regarding flow batteries. Flow batteries differ from conventional (lead and lithium-based)

The challenge of corrosion in next-generation rechargeable metal batteries

Aug 14, 2025 · Despite its profound impact on calendar life, metal corrosion in emerging rechargeable metal-based batteries remains insufficiently understood. The limited

Corrosion of metallic anodes in aqueous batteries

However, the corrosion of metallic anodes seriously deteriorates the battery performance in terms of capacity loss, retarded reaction kinetics, and shortened cycling life. In this review, the

Corrosion Mechanism and Mitigation in Batteries: A Review

May 22, 2025 · Capacity fading, elevated internal resistance, and possible safety risks including thermal runaway are all consequences of corrosion. This paper examines the basic

Investigation of the flow rate optimization of the Zn/LiFePO4

Nov 20, 2023 · In the future, more means are expected to be used to explore its mechanism more accurately. This work provides insights into the mechanisms of flow effects on cycle life and

Mitigating hydrogen evolution reaction and corrosion of zinc

Mar 15, 2024 · Besides suppressing the parasitic reaction (HER) and corrosion of zinc, promoting the key reactions (ORR and OER) of zinc-air batteries by the use of nanofluid electrolytes is

6 FAQs about [Is corrosion of flow battery serious ]

What happens if a battery is corrosive?

Battery corrosion can also lead to leaking or cracked battery cases. The corrosive materials can eat away at the battery casing, causing it to become weak and susceptible to damage. This can result in leaks, which can further contribute to the corrosion and can also pose a safety risk due to the potential for electrolyte leakage.

What is battery corrosion?

Battery corrosion is a common problem that occurs when there is an erosion caused by oxidation or chemical reactions between the battery terminals and the surrounding environment. It can result in a build-up of rust on the battery, which can lead to decreased performance and potentially damage the battery over time.

What are the most common battery problems?

When it comes to batteries, one of the most common problems that many people encounter is corrosion. Battery corrosion occurs when rust, erosion, and oxidation take place on the battery terminals, making it difficult for the battery to function properly.

What are the two phases of a corrosion battery?

Two distinct phases, austenite and martensite which become the anode and the cathode, respectively, of a corrosion battery During martensitic transformation an anodic transient current occurred. Stainless steels are known having a good resistance to general corrosion because they form on their surface a thin chromium rich passive film.

What causes a battery to corrode?

Erosion, also known as corrosion or oxidation, occurs when the chemicals inside the battery react with the metal components of the battery casing or terminals. When a battery is exposed to moisture, heat, or other harsh environmental conditions, the metal components such as the terminals or casing can start to corrode.

What causes galvanic corrosion in metal batteries?

Moreover, galvanic corrosion along with gas evolution will emerge inevitably when metal deposits on Cu foil in metal batteries [12–15]. Also, due to the poor reduction stability of electrolyte solvents, they are notorious for their corrosion with the metal anode in these batteries [16–22].

Learn More

- All-vanadium liquid flow battery device

- Address of the flow battery energy storage cabinet of the Eritrean communication base station

- Is flow battery a new energy source

- Which type of flow battery is better

- Communication base station flow battery technology and management

- Iron-based liquid flow battery energy storage system

- N Djamena New Energy All-vanadium Liquid Flow Energy Storage Battery

- Flow battery manufacturing equipment price

- Flow Battery 2025

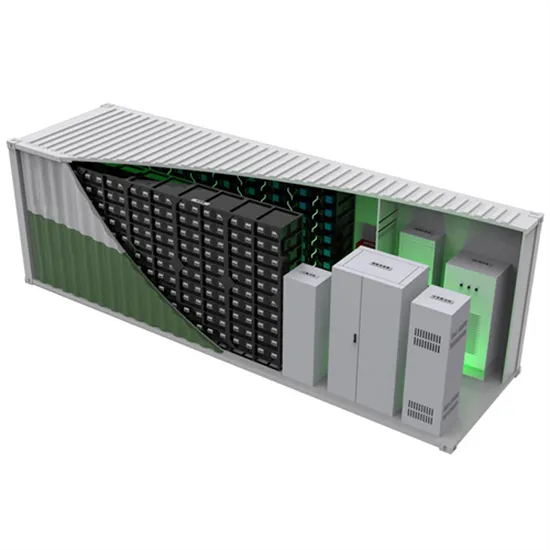

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

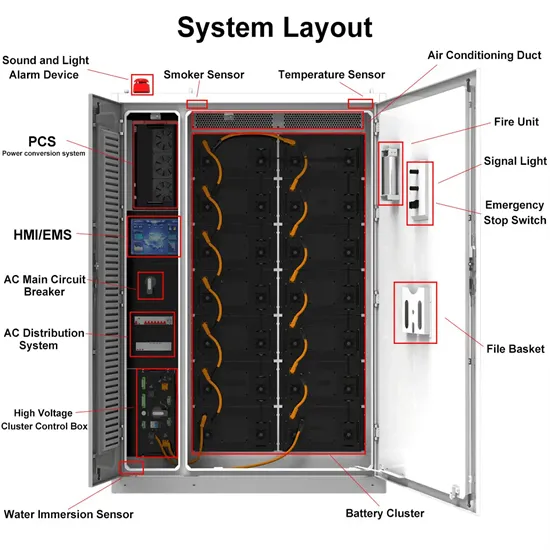

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.