Construction Project Bidding Prices and Price Control

展开更多 In the 21st century, especially after the accession to WTO, Construction project bidding price formation mechanism is the main characteristics of the market price of the Construction

Power Grid Wins Bids for Three Transmission Projects under

Mar 6, 2025 · Power Grid Corporation of India has emerged as the successful bidder under Tariff-Based Competitive Bidding (TBCB) for three projects aimed at establishing an Inter-State

West Asia Photovoltaic Power Inverter Bidding Trends

In West Asia''s booming solar energy sector, photovoltaic power inverter bidding has become as competitive as a desert camel race. With countries like Saudi Arabia and UAE accelerating

Week In South East Asia: Bidding Opens For 40 MW

Apr 3, 2021 · The public bidding is now open for a 40 mW solar project in Kampong Chhnang province. The winning bidder will receive financing from the Asian Development Bank (ADB).

中国能建北京电力设备公司英文站 News BPEG Won the

Oct 25, 2024 · At the beginning of September, BPEG has successfully won the bidding for all four packages of the 500kV COA-SOA and COA-WOA Flexible DC Converter Station Reactor

Grid-Forming Inverters: Project Demonstrations and Pilots

Feb 23, 2024 · Power system operators around the world are pushing the limits of integrating inverter-based resources (IBRs) to very high levels, approaching 100% instantaneous

A System for Tender Price Evaluation of Construction Project Based

Jan 1, 2015 · Tender price evaluation of construction project is one of the most important works for the clients to control project cost in the bidding stage. However,the previously underutilization

ASEAN Power Grid Interconnections Project Profiles

Nov 18, 2024 · The Project Profile is a high-level summary of the ASEAN Power Grid interconnection projects, which is identified through the ASEAN Interconnection Masterplan

Bidding for the Specialized Grid Connection Consultancy

Oct 25, 2024 · II. Project Overview and Scope of Bidding Project overview: Located within the Taiyuan Wusu International Airport, the Project is aimed and tasked to achieve zero-carbon

Procurement of INFRASTRUCTURE PROJECTS

Dec 14, 2021 · Preface These Philippine Bidding Documents (PBDs) for the procurement of Infrastructure Projects (hereinafter referred to also as the "Works") through Competitive

MV-inverter station: centerpiece of the PV eBoP solution

Their outdoor housing allows these switchgear to be installed in PV systems with no additional station enclosure. The state-of-the-art inverters can be operated at DC input voltages of up to

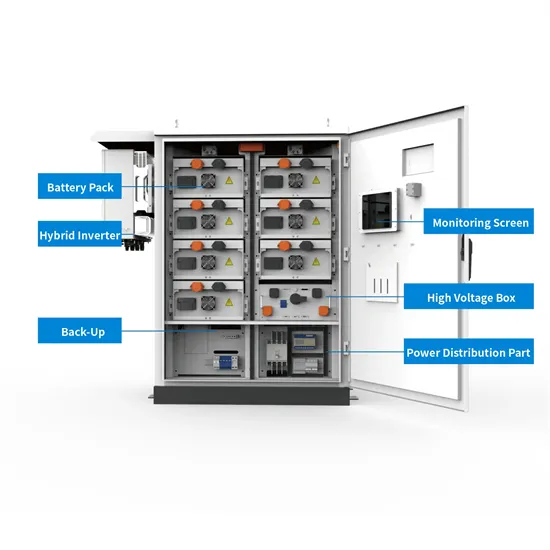

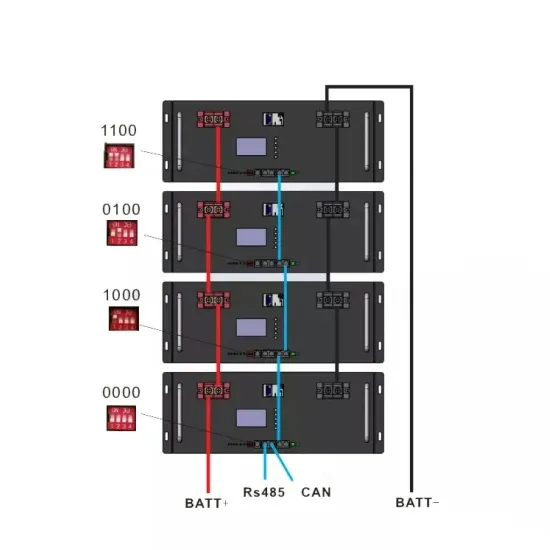

GRID CONNECTED PV SYSTEMS WITH BATTERY ENERGY

May 22, 2023 · The term battery system replaces the term battery to allow for the fact that the battery system could include the energy storage plus other associated components. For

World Bank Document

5 days ago · The factors to consider when selecting inverters include compatibility with module technology, compliance with grid code and other applicable regulations, inverter-based layout,

16GW! Datang 2024-2025 PV Inverter Framework Bidding

On July 16, China Datang Corporation Limited launched a framework tender for photovoltaic inverters in 2024-2025. The project is divided into three sections, with a total procurement

China Unicom LTE phase III bidding for 167 thousand base stations

On March 1st, China Unicom LTE phase III wireless main equipment bidding for 167 thousand base stations ended. According to the public results, four major equipment vendors all won the

6 FAQs about [Bidding for West Asia Communication Base Station Inverter Grid Connection Construction Project]

How does the grid code affect inverter sizing and Technology?

The grid code affects inverter sizing and technology. The national grid code might require the inverters to be capable of reactive power control. In that case, over-sizing inverters slightly could be required. The grid code also sets requirements on THD, which is the level of harmonic content allowed in the inverter’s AC power output.

What equipment does a PV substation need?

The substation will also have the required grid interface switchgear such as circuit breakers and disconnects for protection and isolation of the PV power plant as well as generation and supply metering equipment.

Which countries are co-financing a 100 MW power plant?

In June 2010 the World Bank approved a $200m loan to co-finance a 100 MW power tower plant near Upington, South Africa. In Rajasthan, India, ACME are commissioning a 10 MW plant, based on technology from eSolar (USA), and have plans to scale up to production of 50 MW units and implementation of utility-scale projects.

Where is the PV module market based?

The PV module market is dominated by a few large manufacturers based predominantly in Europe, North America and China. Selecting the correct module is of fundamental importance to a PV project, keeping in mind the numerous internationally accepted standards.

Who is responsible if a PV plant is connected to a grid?

Responsibility for this is defined in the grid connection contract. Normally, it is the grid operator‘s onus to maintain the equipment in the grid operator‘s boundary—and there will be a cost to be paid by the PV plant owner. The unusual electrical properties required for PV cells limit the raw materials from which they may be manufactured.

Where are substations and metering points located?

The substation and metering point are often external to the PV power plant boundary and are typically located on the network operator’s property.

Learn More

- Libya communication base station inverter grid connection construction bidding

- Ghana communication base station inverter grid connection maintenance construction

- Beijing communication base station inverter grid connection construction time point

- Samoa communication base station inverter grid-connected construction project bidding

- Timor-Leste 5G communication base station hybrid energy construction project bidding

- Inverter connection to the grid for small communication base stations in Central Asia

- Energy storage ESS rate of communication base station inverter grid connection

- Communication base station inverter grid connection planning application

- Australian outpost communication base station inverter connected to the grid 6 9MWh

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.