Help for people buying the "12-48 Volt 1800/2500 Watt ZVS

Aug 19, 2025 · A ZVS driver like these is extremely power hungry and the higher voltage, the worse it gets So a 1000W power supply at 36V might be good enough for running the 1000W

10kW 240Vac-line-powered ZVS induction heater?

Jul 6, 2021 · 10kW 240Vac-line-powered ZVS induction heater?I would have thought fat litz > foil for the transformer. Looking at the transformer in the Panasonic microwave oven inverter on

Zero-Voltage-Switching Single-Phase Full-Bridge Inverter

May 29, 2020 · Abstract: Single-phase zero-voltage-switching (ZVS) inverter with wide bandgap devices has higher efficiency and power density. However, the dc-side capacitor of the inverter

Beware of Zero Voltage Switching

Sep 9, 2021 · Zero voltage switching (ZVS) is considered the panacea for all the challenges posed by high frequency and higher efficiency requirements. While ZVS is indeed a blessing,

Modeling and Control of Inverter Zero-Voltage-Switching for

Sep 24, 2019 · It''s very important to maintain the inverter zero-voltage-switching(ZVS) for inductive power transfer (IPT) system, especially for those high power applications. The ZVS

Loadâ independent inverse classâ E ZVS inverter and its

May 3, 2022 · This paper proposes a load-independent inverse class-E zero-voltage switching (ZVS) inverter. The proposed inverter achieves the constant output current and the ZVS at any

24v Inverter, 24v DC to 120v/240v AC Power Inverter | inverter

24V 600w inverter with peak power 1200w, which is a modified sine wave, converts your car battery power to AC power 110/120 Volt or 220/230/240 Volt for options, with a safe charging

Amazon : Power Converter 12 Volt To 220

1-48 of over 30,000 results for "power converter 12 volt to 220" Results Check each product page for other buying options. Price and other details may vary based on product size and color.

Soft-switching SiC power electronic conversion

Aug 20, 2019 · In the proposed zero-voltage-switching (ZVS) technique, only one simple auxiliary circuit is employed to realize the ZVS operation for all power

Mazilli ZVS Induction Heater (With IGBT''s)

Mar 11, 2017 · I have been told there are issues when trying to use IGBT''s with this circuit, but I am not sure if these people were referring to the "brick" type

questions about inverters for a solar power system with both 220

Dec 25, 2019 · I''m assuming that the 220VAC out of an inverter is like residential 220 VAC with two 110VAC ''hot'' legs and a ground. First off, is my assumption correct? and if so, how tolerant

6 FAQs about [Zvs inverter to 220 volts]

What is a ZVS based inverter?

A ZVS-based Royer oscillator or Class-D inverter ensures soft switching, preventing thermal stress on IGBTs or MOSFETs. The load impedance (Zload) is matched to the inverter output using a resonant tank, enabling ZVS over a wide range of operating conditions.

What is zero voltage switching (ZVS)?

The article discusses the concept and working principles of Zero Voltage Switching (ZVS), a technique in power electronics aimed at minimizing switching losses and electromagnetic interference. It also covers ZVS applications, advantages, limitations, and components involved in implementing this method, particularly in heating control systems.

Does a single-phase zero-voltage-switching (ZVS) inverter have a DC-side?

Abstract: Single-phase zero-voltage-switching (ZVS) inverter with wide bandgap devices has higher efficiency and power density. However, the dc-side capacitor of the inverter will suffer double line frequency ripple and reduces the lifetime of the dc bus capacitor.

Why is ZVS important in power electronics?

ZVS is important in power electronics because it reduces switching losses, improves energy efficiency, and minimizes heat generation in switching circuits. It also helps to reduce electromagnetic interference (EMI) and noise. How does ZVS achieve zero voltage across the switching device?

What is a ZVS inverter with APD circuit?

The gate drive pulses are designed to realize the ZVS turn- on for the main switches of both APD circuit and single-phase full-bridge inverter. Circuit operation stages are analyzed and ZVS conditions are given. Finally, the proposed ZVS inverter with APD circuit is verified on a 1.5-kW inverter prototype.

How does a ZVS converter work?

STATUS CIRCUIT VALUES In a ZVS converter operating under ideal conditions, the on-time of the switch approaches zero, and the converter will at maximum frequency and deliver zero output voltage.

Learn More

- Inverter 12v to 220 volts

- 12v inverter or 220 volts

- How many volts can the inverter convert to 220

- Inverter 220 to 30 volts

- 48v to 220 inverter 3000 watts

- 48 220 inverter

- How many volts does the inverter output voltage change

- How many volts does a photovoltaic boost inverter usually have

- 320 to 220 inverter

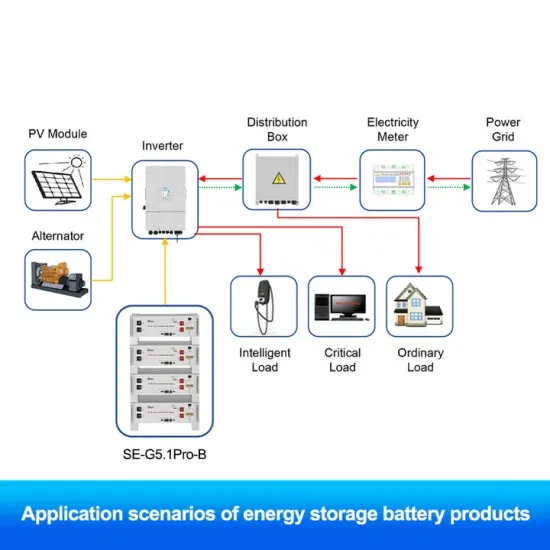

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.