Battery Cabinet Phase Requirements | HuiJue Group E-Site

Expert Predictions: The 2030 Phase Paradigm As solid-state batteries approach commercialization, their inherent capacitance characteristics may fundamentally alter cabinet

CASE STUDIES IN BATTERY RISK ASSESSMENT

Mar 1, 2024 · Many batteries can be safely sectionalized without crossing the restricted approach boundary or arc flash boundary where PPE would be required. In batteries where this is not

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · Example: a 45"L rack will need an extra 3" per side or a minimum cabinet length of 51"L (round up to 60"L). If a fan is not required, 1" of space per side is acceptable, so a 48"L

Atomic-Scale Analysis of Biphasic Boundaries in the Lithium

Jul 23, 2020 · (Note: you will need to create a separate account there.) Atomic-Scale Analysis of Biphasic Boundaries in the Lithium-Ion Battery Cathode Material LiFePO4 ACS Applied

Key Considerations for Designing an Efficient EV Battery

Jul 27, 2023 · Battery Data Analytics "We''re working with NI on a long-term sustainable solution that allows us to op the insights that we need to improve battery performance. NI''s lifecycle

Thermal Simulation and Analysis of Outdoor Energy Storage Battery

Jan 8, 2024 · Maintaining low and uniform temperature distribution, and low energy consumption of the battery storage is very important. We studied the fluid dynamics and heat transfer

Thermal Simulation and Analysis of Outdoor Energy Storage Battery

Jan 8, 2024 · We studied the fluid dynamics and heat transfer phenomena of a single cell, 16-cell modules, battery packs, and cabinet through computer simulations and experimental

Arc-in-a-Box: DC Arc Flash Calculations Using a

Jan 10, 2023 · A method is proposed for calculating the incident energy and the arc flash boundary distance for dc systems when an arc is bounded inside a space such as a battery

Holistic battery system design optimization for electric

Aug 1, 2022 · This study presented an in-depth system-oriented analysis of different cell geometry integration as well as optimization of the overall installation space for battery systems with

Energy flow analysis of laboratory scale lithium-ion

May 26, 2021 · The reason for this is the different battery technologies, assumptions, system boundaries, and sim-plifications that are used for the determination of the energy

Study on performance effects for battery energy storage

Feb 1, 2025 · First, thermal performance indicators are used to evaluate the temperature field and velocity field of the battery energy storage cabinet under different air outlet configurations. It

Battery Energy Storage Systems Report

Jan 18, 2025 · This information was prepared as an account of work sponsored by an agency of the U.S. Government. Neither the U.S. Government nor any agency thereof, nor any of their

Battery Cabinet Cost Structure and Optimiza-tion

Jan 12, 2024 · height of the battery cabinet is not as critical. Having a battery cabinet with the same height as the UPS device is visually advantageous, but this does not have a major

WORKPLACE GUIDE TO ARC FLASH

Jan 18, 2025 · With the rising frequency of reported arc flash accidents, and the potential for serious injury or death, arc flash is a serious concern. It''s important to increase safety and

Experimental and numerical investigation on thermal

Dec 5, 2015 · In this paper, the flow field and temperature distribution inside an outdoor cabinet are studied experimentally and numerically. The battery cabinets house 24 batteries in two

Understanding System Boundaries in Life Cycle Assessment

Jun 11, 2024 · What are System Boundaries? System boundaries are crucial for Life Cycle Assessments (LCA). They define what processes and stages across a product''s life cycle are

Grid-Scale Battery Storage: Frequently Asked Questions

Jul 11, 2023 · What is grid-scale battery storage? Battery storage is a technology that enables power system operators and utilities to store energy for later use. A battery energy storage

Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · In-depth analysis of ESS Battery Enclosure size matching and compatibility optimization technology, covering large-capacity battery cells, CTP integration, liquid cooling

Optimal test case generation for boundary value analysis

Feb 13, 2024 · Boundary value analysis (BVA) is a common technique in software testing that uses input values that lie at the boundaries where significant changes in behavior are

Battery Storage Cabinets: The Backbone of Safe

Apr 11, 2025 · Explore the essential role of battery storage cabinets in modern energy systems, highlighting their design, safety features, and applications

CASE STUDIES IN BATTERY RISK ASSESSMENT

Mar 1, 2024 · CASE 1 is rated at 160 kVA / 144 kW, 480/277 VAC, and is an uninterruptable power supply (UPS) with a battery, shown in Fig. 1, contained in a single electronics cabinet

Techno-economic analysis for lithium-ion battery

Jan 15, 2025 · Li Zeng discusses how techno-economic analysis can be used for scaling up clean technologies, such as lithium-ion battery manufacturing and recycling, from lab to industrial scale.

What are the Essential Site Requirements for Battery Energy

Nov 19, 2024 · Whate are the key site requirements for Battery Energy Storage Systems (BESS)? Learn about site selection, grid interconnection, permitting, environmental considerations,

(PDF) Optimized cabinet parameters for drying

Mar 1, 2023 · Hot-airflow desiccation is a commonly applied technique for drying lithium-ion batteries. However, most drying cabinet designs currently suffer

Utility-Scale Battery Storage | Electricity | 2024 | ATB | NREL

The battery storage technologies do not calculate levelized cost of energy (LCOE) or levelized cost of storage (LCOS) and so do not use financial assumptions. Therefore, all parameters are

Safety boundary analysis for lithium-ion batteries via

May 29, 2022 · Acquiring the safe boundary of battery is beneficial to the safety risk evaluation of power battery and to offer the early warning signs. The method to accurately measure the

Considerations For Battery Room Design, Battery Stands and

This article looks at the preferred designs for battery rooms and discusses how batteries should be laid out to give a safe environment. Alternative battery stand types are discussed to

5 FAQs about [What boundaries are needed for battery cabinet analysis]

What are the different types of battery risk assessment?

Battery risk assessment can be broken up into specific hazards. We focus in this paper on electrical hazards which include electric shock, arc flash, and thermal hazards. Non-electrical hazards may include chemical (e.g., electrolyte expulsion) or battery fire / explosion, which should also be considered.

Do battery cabinets cause arc flash?

Battery cabinets come in many forms. Anecdotal evidence suggests that the greatest risk of arc flash is in cabinets in which top-terminal containers are installed.

What are administrative controls in a battery system?

These can be documented in the battery risk assessment required by NFPA 70E . Other papers have discussed higher level elimination and engineering controls [1,3]. Administrative controls are the procedures and policies employed to keep workers safe when performing a given task. The primary administrative control in battery systems is the

Why are battery terminals covered with polycarbonate?

This is a poor design given that arc flash risk in batteries increases in both likelihood and consequence very little opposite polarity separation . All terminals are covered with clear polycarbonate to prevent inadvertent contact with electrical conductors.

What are safe work practices for battery technicians?

In response, safe work practices are being refined and updated to protect a new workforce of battery technicians . These work practices are based on the general principles of hazardous energy control which can be difficult to understand or apply to specific battery systems with specific hazards.

Learn More

- What kind of protection frame should be used for battery cabinet

- What is a battery cabinet assembly company

- What battery cabinet companies are there in Burundi

- Lithium battery station cabinet analysis

- Battery Cabinet Thermal Management Analysis Specification

- What are the battery cabinet manufacturers near Sao Tome

- The latest analysis of energy storage battery cabinet market

- What are the technical contents of the battery cabinet

- What is the cold plate of the battery cabinet

Industrial & Commercial Energy Storage Market Growth

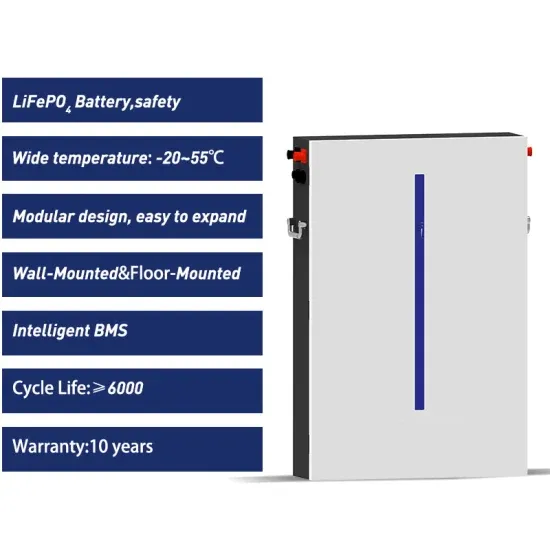

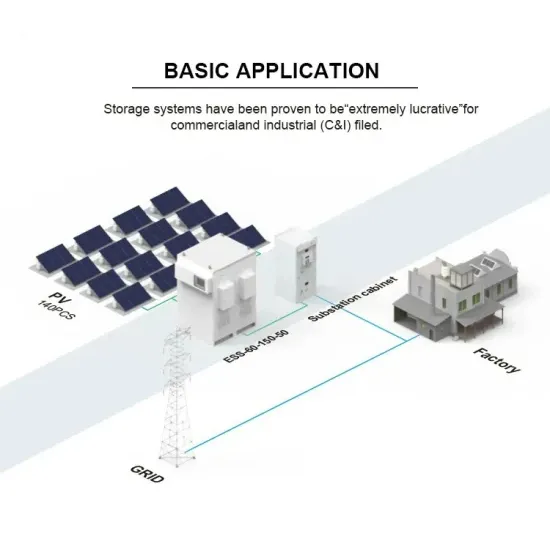

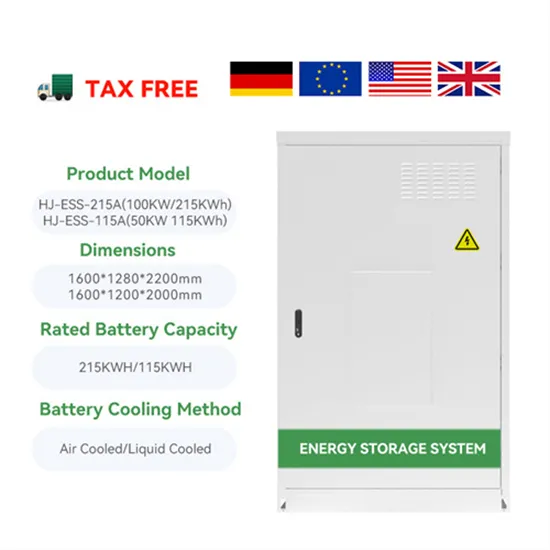

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

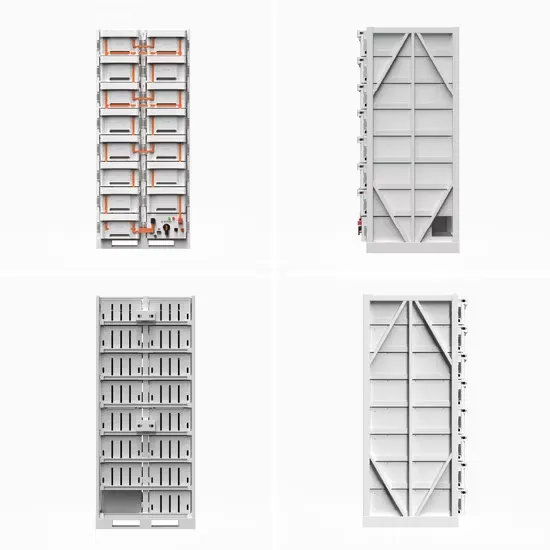

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.