Design of high gain base station antenna array for mm-wave

Mar 25, 2023 · Millimeter wave (mm-Wave) wireless communication systems require high gain antennas to overcome path loss effects and thereby enhance system coverage. This paper

Grounding architecture design for Wireless Base Stations

Nov 1, 2012 · In this paper several EMC grounding architectures for interconnection of PCBs, backplanes, and card cages to enclosures for Wireless Base Stations are described in the

Technical requirements for lightning protection and grounding

The grounding of mobile base stations should adopt joint grounding, which is to connect the protection ground of various communication system equipment, the working ground and the

Ground Base Station Antenna Design for Air-to-Ground

Mar 11, 2024 · The digital airspace offers new opportunities in the sky, such as mission-critical mobile broadband solutions and high altitude communication for aircraft [4]. In the latter use

LBI-39185C, Specifications, Guidelines, and Practices,

Jul 15, 2008 · 1.1 SCOPE This specification establishes minimum standards for the design, fabrication and installation of latticed steel guyed and self-supporting towers including Portland

Microsoft PowerPoint

Feb 19, 2016 · The primary goal of the communication subsystem is to provide a link to relay data findings and send commands to and from the satellite. Communication subsystem will ensure

5.3.4 Grounding Specifications for Communications Power

1 All communication devices and auxiliary devices (such as mobile base stations, transmission and switching devices, power supply devices) in the equipment room should be grounded for

Typical Grounding of Mobile Communication Base Station

It is extremely difficult to make the grounding resistance of the base station''s ground grid small and meet the regulatory requirements. Therefore, the reasonable design of the grounding

Interface specifications for protection and grounding in wireless base

Base transceiver stations (BTSs), as they are often called, are equipped with antennae that maybe installed on towers or high-rises. A BTS must also communicate with its controller,

Interface specifications for protection and grounding in wireless base

In recent years, the deployment of distributed communication systems, particularly wireless base stations, has increased. These systems are typically installed in self-contained metallic

Wireless Base Stations

Oct 22, 2009 · In radio communications, a base station is a wireless communications station installed at a fixed location and used to communicate as part of a push-to-talk two-way radio

6 FAQs about [Communication wireless base station grounding specifications]

What are the standards for cell site grounding & telecommunications tower grounding?

Our cell site grounding,telecommunications grounding and communication tower grounding methods closely follow the Motorola R56 standards and IEEE Std 142-1991 and IEEE Std 142-2007 recommended Practice for Grounding of Industrial and Commercial Power Systems guidelines for cell site and telecommunications sites.

Who provides cell site grounding & telecommunication tower grounding services?

The experts at E&S Grounding Solutions provide comprehensive cell site grounding and telecommunication grounding solutions for Cell Site grounding or BTS Cellular Base Station grounding. Our cell site grounding and telecommunication tower grounding services protect your valuable equipment!

What is a good grounding electrode resistance for a communication tower?

According to the IEEE Std 142-1991 and IEEE Std 142-2007 (The Green Book), the communication tower grounding electrode resistance of large electrical substations should be 1 Ohm resistance or less. For commercial and industrial substations including cell site and telecommunications sites the recommended resistance to ground is 5 Ohms or less.

Why is electrical grounding important?

Proper electrical grounding is essential for Cell Sites, BTS Cellular Base Stations, telecommunications or wireless network equipment deployement.

Can a communication tower be grounded with a 5 ohm resistivity test?

With proper soil resistivity testing however, we can provide communication tower grounding solutions that will achieve 5 ohm resistance to ground and meet the stringent requirements such as the Motorola R56 standard to keep your valuable equipment within warranty.

How do you ground a TMGB cable?

l Green #6 AWG grounding conductor with appropriate lugs from the side of the cable tray down to TMGB or TGB. Drill the side of the cable tray and install a 1⁄4” fine th appropriate length bolt, making su e that the bolt does extend into the wire management part of the tray. G. Ground of Equipment Frame.1. Install Telecomm

Learn More

- Communication Green Base Station RRU Installation Specifications

- Barbados Wireless Communication Base Station Energy Management System

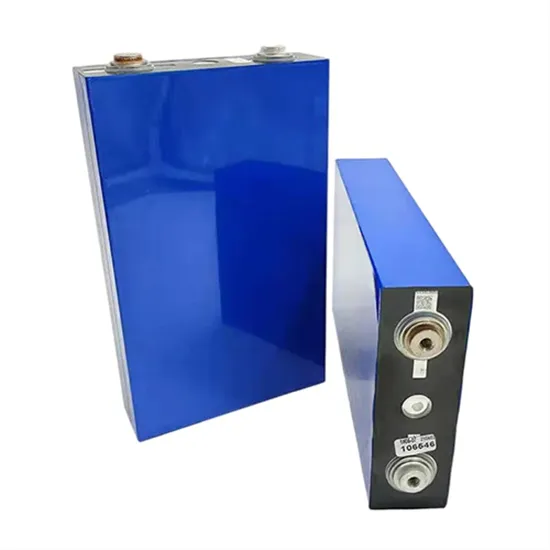

- Battery energy storage system grounding wire for communication base station

- Communication base station supercapacitor installation management specifications

- Site communication of wireless outdoor base station AP energy storage cabinet

- What are the technical specifications for grid-connected operation and maintenance of communication base station inverters

- Communication base station inverter grounding regulations

- Benin wireless communication base station lithium ion battery

- Price of photovoltaic wireless communication base station battery

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.