Pop Up Power: Well-designed outdoor spaces in healthcare

Aug 13, 2025 · Pop Up Power Supplies provides three different types – a pop up or retractable unit, an in-ground unit or a power bollard. All three have specific advantages, so the most

Healthcare Facilities and Power Outages

Jul 1, 2020 · Electrical power supply systems may fail during a power disruption, which could leave the hospital unable to deliver safe care, treatment, and services to patients.

Everything You Need to Know About Installing

Apr 28, 2025 · To safely use electrical equipment outside, it''s advisable to have a dedicated external power point rather than a trailing extension lead from inside

POWER CONTINUITY IN HEALTHCARE: SIZING AND

Mar 28, 2018 · Today, of course, the power system in healthcare facilities must support more than just standard IT systems. Critical operations throughout the hospital or clinic, such as

Points to consider when selecting external power

Jul 26, 2018 · Outside of a hospital environment, the external power supply could be subject to the ingress of water, either by rainfall or even a spilt drink. Two levels of ingress protection (IP) are

Poweron Enertech Launches Advanced Isolated Power Supply for Medical

Oct 1, 2024 · Poweron Enertech proudly announces the launch of its latest innovation: an advanced Isolated Power Supply with integrated Online Double Conversion UPS, specifically

100 days of UCH without power: Challenges and

Feb 8, 2025 · The report includes goals to achieve a sustainable power supply for the hospital in the short, medium and long term. According to him, the short

The protection of medical emergency power supply, outdoor power supply

Aug 23, 2023 · Especially in the medical field, electricity is critical to the management and care of patients. However, in some emergency situations, such as disasters, natural disasters or

An Introduction to Electrical Systems for Medical Facilities

Aug 29, 2018 · Rugged mechanical and electrical design allows our equipment to withstand input voltage drops and transients as well as shock and vibration in industrial environments.

Outdoor power distribution units

Nov 27, 2024 · A versatile range of discreet, retractable service units to suit every location. Buried, flip lid Units for continuous, round-the-clock unattended use. Outdoor power supplies

Design characteristics on the indoor and outdoor air environments

Jan 1, 2022 · According to the discussion of the design method and operational effect for Wuhan Huoshenshan Hospital, this paper summarized the design control points of indoor and outdoor

Electrical Works of the Hospital Building | SpringerLink

Dec 7, 2023 · Power supply sources in hospitals can include the primary power supply (PPS), secondary power supply (SPS) and tertiary power supply (TPS). Transformers are employed

6 FAQs about [Outdoor power supply outside the hospital]

Why do hospitals need to test electrical power supply systems?

Electrical power supply systems may fail during a power disruption, which could leave the hospital unable to deliver safe care, treatment, and services to patients. Testing these systems increases the chances of detecting reliability problems and reduces the risk of losing this critical resource when it is most needed. Under Standard EC.02.05.07:

Are healthcare facilities prepared for power outages?

This phenomenon recurs for a multitude of reasons, and although healthcare facility leaders are responsible for preparing their facilities for power outages in accordance with applicable regulation, the whole community (to include all levels of government and utility operators) can help improve these facilities’ resilience to power outages.

What are emergency power supply systems?

In the event of power interruption, emergency power supply systems provide emergency standby power to facilities. These systems are susceptible to design, capacity, and maintenance issues. Recurring challenges and themes are discussed below, and general information about stand-by power generation and utility power is available in Appendix A.

What are portable power solutions for medical devices?

Portable power solutions for medical devices are essential to providing lifesaving benefits, increasing patient mobility and independence, and improving healthcare delivery in emergencies. Different types of portable power solutions exist, including battery-powered devices, solar-powered devices, and fuel-powered generators.

Can a battery power station power medical equipment?

Battery power stations are a popular and convenient option for powering medical equipment. These devices come in various shapes and sizes, with some specifically designed for medical use. Battery-powered devices typically provide portable power solutions that can last anywhere from a few hours to several days, depending on the device’s power needs.

How do I choose a portable power solution for my medical device?

When choosing a portable power solution for your medical device, it is crucial to consider its compatibility with the device. Not all power sources are compatible with every medical device, so it’s essential to research before making a purchase. For example, suppose you’re using a CPAP machine that requires DC 24V and 3A.

Learn More

- Austria Outdoor Power Supply Design

- Whether to use outdoor power supply or generator for suburban travel

- Male outdoor power supply work recommendation

- Outdoor power supply comparison zendure

- New Energy Vehicle Outdoor Power Supply

- Dn outdoor power supply

- Nicosia Outdoor Telecommunication Power Supply 5kWh BESS

- Tonga outdoor mobile energy storage power supply

- M1 outdoor power supply

Industrial & Commercial Energy Storage Market Growth

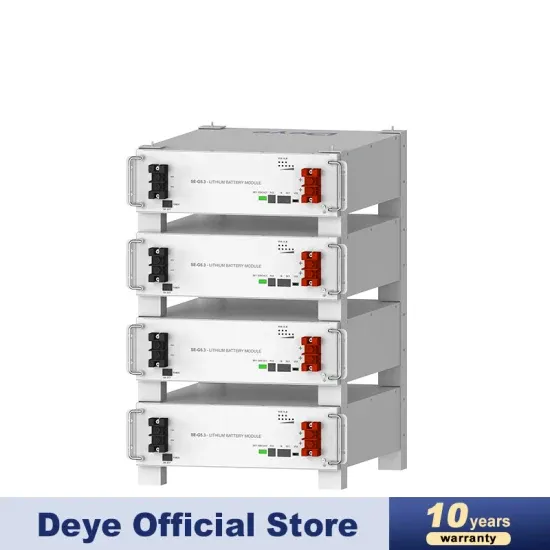

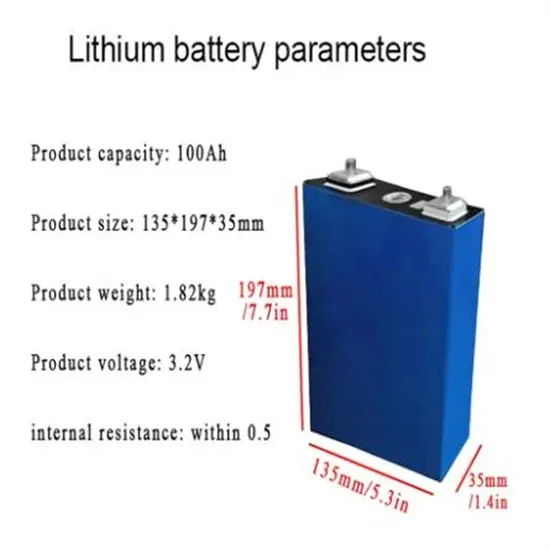

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.