Space Vector Pulse Width Modulation Strategy for Three Phase

Mar 16, 2025 · Various algorithms exist for controlling the output voltage of the voltage source inverter (VSI), but they all tend to produce unwanted harmonics aside from the desired

Space Vector PWM Scheme for Three Phase Three Level T-type NPC Inverter

Jul 6, 2019 · Multi-level inverters (MLI) have been widely used for dc to ac power conversion for different applications. Different PWM methods are used to control the multilevel inverters.

SPACE-VECTOR PWM WITH TMS320C24X USING

Feb 1, 1999 · This program implements an INT driven sampling and control loop ; for three-phase AC induction motor control through a three-phase ; voltage source inverter.

Space Vector Pulse Width Modulation Strategy for Three Phase

Mar 16, 2025 · Adjustable speed drives for three-phase induction motors and permanent magnet synchronous motors necessitate varying both voltage and frequency. Achieving this

Design of Three Phase Inverter Using Space Vector Pulse

Aug 4, 2022 · Space Vector PWM (SVPWM) refers to a special switching sequence of the upper three power transistors of a three-phase power inverter. Because of its superior performance

Space-Vector Modulation of a Three-Level NPC-Inverter

Aug 5, 2021 · This paper introduces a 3-level Neutral-Point-Clamp inverter using space vector pulse width modulation approach as a control strategy simulation model developed and

Space Vector PWM based three phase inverter

Apr 20, 2010 · The model simulates the Space Vector PWM based three phase inverter. Line voltages, phase voltages and filtered voltages can be seen on scope. Parameters such as

Design and Simulation of Space Vector PWM for Three

May 26, 2014 · Space Vector Pulse Width Modulation (SVPWM) has become the successful techniques to construct three phase sine wave Voltage Source Inverter (VSI) parallel to control

Center-Aligned Space Vector PWM Realization for 3

Apr 1, 2023 · ABSTRACT The space vector pulse width modulation (SVPWM) has been widely used in 3- phase inverter control system. The most effective way for the MCU implementation

Space Vector Modulation (SVM)

Mar 8, 2022 · Space Vector Modulation (SVM) was originally developed as vector approach to Pulse Width Modulation (PWM) for three phase inverters. It is a more sophisticated technique

Space Vector Pulse-Width Modulation of Three-Phase Two

Dec 27, 2024 · Models for space vector pulse-width modulation (SVPWM) of three-phase two-level inverter and diode-clamped three-level inverter (DCTLI) are presented in Chap. 4. Case

High Performance FPGA Based Digital Space Vector

Jun 20, 2023 · This paper focuses on the design of a low power and high performance FPGA based Digital Space Vector Pulse Width Modulation (DSVPWM) controller for three phase

SPACE-VECTOR PWM WITH TMS320C24X USING

Feb 1, 1999 · Popular examples are sinusoidal PWM, hysteric PWM and the relatively new space-vector (SV) PWM. These techniques are commonly used for the control of AC induction, BLDC

Space vectors techniques in three-level five-phase inverters

Oct 2, 2024 · In this work, the space vector pulse width modulation methods are designed for three-level five-phase inverter (3LFPI) in order to eliminate the CMV. The choice of 3LFPI is

Space Vector Modulation Technique for 3‐Level

Jul 14, 2016 · For a three-phase two-level converter, the aim of the Space Vector Modulation is to select the appropriate space vectors to apply and their

Study and implementation of space vector pulse width

Abstract. Three-phase two-level inverters using space vector modulation (SVPWM) technology are one of the most popular inverter architectures today. The process of designing and

A Simple Space Vector Modulation Algorithm for Multi

Jan 16, 2017 · Abstract: This paper proposes the reverse mapping method for generation of a space vector pulse width modulation (SVPWM) for three phase multi level voltage source

Digital Implementation of Space Vector PWM for Three Phase Inverter

Sep 30, 2021 · Digital Implementation of Space Vector PWM for Three Phase Inverter with Simplified C-Block PSIM Utilization Published in: 2021 International Electronics Symposium (IES)

Implementation of space vector modulation for two level

Aug 8, 2025 · In this paper, a real-time digital implementation of SVPWM algorithm for three-phase two level inverter using dSPACE DS1104. The results obtained from the

Analysis of Space Vector PWM for Three Phase Inverter

Jan 30, 2016 · ABSTRACT: Three phase voltage source inverters are being used extensively nowadays in industries to supply three-phase induction motor with variable frequency and

Modified Space Vector Modulation Technique for Three Phase

In this paper, the two new pulse patterns corresponding to two switching sequences in space vector modulation are applied for the three-phase three-level T-type inverter.

Generalized Space-Vector-Modulation Method for Soft-Switching Three

Sep 25, 2020 · Three-phase inverters are usually required to output reactive power in electric machine drives, renewable energy generation, static var generators, and other power

SVPWM vs SPWM modulation techniques

Aug 19, 2021 · What is the difference between Space Vector (SVPWM) and Sinusoidal Pulse Width Modulation (SPWM)? This article presents the advantages of the SVPWM technique

6 FAQs about [Space vector three-phase inverter]

What is space vector pulse width modulation (SVPWM)?

The space vector pulse width modulation (SVPWM) has been widely used in 3- phase inverter control system. The most effective way for the MCU implementation of the SVPWM is the center-aligned PWM, because the PWM module in the MCU can generate the center-aligned PWM easily.

Why is SVPWM used in 3 phase inverter control system?

Table 3. Table 4. Table 5. The SVPWM has been widely used in 3- phase inverter control system because; it has a higher utility efficiency of DC-side voltage than the sine pulse width modulation (SPWM). Although the SVPWM has many advantages, it is difficult to implement.

What is space vector modulation (SVM)?

Space Vector Modulation (SVM) was originally developed as vector approach to Pulse Width Modulation (PWM) for three phase inverters. It is a more sophisticated technique for generating sine wave that provides a higher voltage to the motor with lower total harmonic distortion.

Can a 3-level 3-phase inverter SVPWM be implemented?

The algorithm can be used to implement the 3-level 3-phase inverter SVPWM. However, because the impact caused by the dead-time and the unbalance of the DC side voltage are not considered, further research is required. Therefore, we must pay special attention to the limitation of the method.

What is the topology of a two-level three-phase inverter?

The topology of a two-level three-phase inverter is presented in the figure below. In the αβ frame, each switching state of the inverter is represented by a space vector. Then, since the DC bus should not be short-circuited, the upper and lower switches of each leg must operate in a complementary way.

Why is space vector PWM required in AC drives?

In addition, SVPWM technique offers flexible control of output voltage as well as frequency which is an indeed requirement in ac drives. Hence, to obtain good voltage transfer and reduced distortion space vector PWM is required. Space vector PWM can produce about 15% higher output voltage than sine PWM.

Learn More

- Inverter voltage space vector control

- Amsterdam three-phase 15kw off-grid inverter

- Syria three-phase inverter sales manufacturers

- High power three-phase pwm inverter

- Inverter three-phase energy storage

- North Asia three-phase inverter manufacturer

- Huawei inverter three-phase range

- Photovoltaic off-grid energy storage inverter three-phase

- What brand of three-phase inverter is good

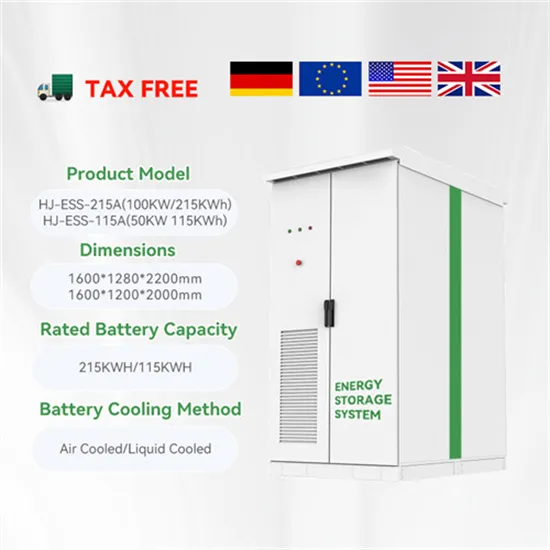

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.