Analysis of safety technical standards for hydrogen storage in fuel

Jul 22, 2024 · This paper studied the safety requirements of the GTR13 compressed hydrogen storage system, analyzed the current hydrogen storage safety standards for fuel cell vehicles

Advancement of fuel cells and electrolyzers technologies and

Jun 1, 2023 · A comprehensive review with a more specific assessment of fuel cell/electrolyzer comprised of green hydrogen energy (GHE) storage technologies for the widespread

Volume B42 Fuel Cells & Industrial Batteries

May 9, 2022 · The Fuel Cells & Industrial Batteries industry consists of companies that manufacture fuel cells for energy production and energy storage equipment such as batteries.

Safety, Codes and Standards – 2022

4 days ago · These codes and standards provide the technical basis to facilitate and enable the safe and consistent deployment and commercialization of hydrogen and fuel cell technologies

3.7 Hydrogen Codes and Standards

Oct 11, 2007 · 3.7.2 Technical Approach The Hydrogen Program recognizes that domestic and international codes and standards must be established along with affordable hydrogen and

3.7 Hydrogen Safety, Codes and Standards

Jul 5, 2013 · The Safety, Codes and Standards sub-program (SCS) facilitates deployment and commercialization of fuel cell and hydrogen technologies by developing information resources

Hydrogen Technologies Safety Guide

Jan 19, 2015 · What are hydrogen technologies? For the purposes of this report they are processes that use or produce hydrogen. Hydrogen can be used as fuel to power internal

The role of fuel cells in energy storage

Mar 1, 2000 · A fuel cell-based energy storage system allows separation of power conversion and energy storage functions enabling each function to be individually optimized for performance,

IEC work for energy storage

Nov 14, 2022 · The objective is to develop performance test methods for power storage and buffering systems based on electrochemical modules (combining electrolysis and fuel cells, in

Hydrogen Storage | Hydrogen and Fuel Cells | NREL

Feb 6, 2025 · Hydrogen Storage With support from the U.S. Department of Energy (DOE), NREL develops comprehensive storage solutions, with a focus on hydrogen storage material

Hydrogen and Fuel Cell Technologies Office Multi-Year

May 4, 2024 · Goals and Objectives The overarching goal of the Safety, Codes and Standards (SCS) subprogram is to enable the safe deployment and use of hydrogen and fuel cell

Stationary Fuel Cell Application Codes and Standards:

Sep 30, 2013 · Table 1 summarizes key gaps in existing stationary fuel cell application codes and standards identified during analysis. The individual sections provide additional extensive

NFPA 855 Standard for the Installation of Stationary Energy Storage

Aug 14, 2025 · This standard provides the minimum requirements for mitigating the hazards associated with Energy Storage Systems. It is applicable to, among other systems, to FLOW

RENEWABLE ENERGY AND ENERGY STORAGE STANDARDS

Dec 19, 2023 · SANS 62282-3-100:Fuel cell technologies Part 3-100: Stationary fuel cell power systems – Safety SANS 61427-1:Secondary cells and batteries for renewable energy storage -

Stationary and Portable Fuel Cell Systems Codes and

Dec 7, 2012 · Stationary and Portable Fuel Cell Systems Codes and Standards Citations This document lists codes and standards typically used for Stationary and Portable Fuel Cell

Stationary Fuel Cell Application Codes and Standards:

Sep 30, 2013 · Executive Summary Codes and standards are implemented to ensure that processes and products meet uniform requirements. These requirements pertain to either

Review of Energy Storage Devices: Fuel Cells,

Nov 4, 2024 · In fuel cells, electrical energy is generated from chemical energy stored in the fuel. Fuel cells are clean and efficient sources of energy as

Analysis of the standard system of China for hydrogen

Feb 27, 2022 · The innovation of hydrogen energy and fuel cell technology promotes the development and application of fuel cell vehicle, which also requires the real-time follow-up of

Hydrogen Codes and Standards

Mar 8, 2006 · Developed draft template for national standards, codes, and regulations for hydrogen vehicles, fueling/ service/parking facilities, vehicle/facility interface, and on-site

Energy Storage, Fuel Cell and Electric Vehicle Technology

Dec 10, 2020 · The energy storage components include the Li-ion battery and super-capacitors are the common energy storage for electric vehicles. Fuel cells are emerging technology for

IEC/TS 62282-8-201 Energy storage systems using fuel cell

Apr 19, 2025 · This part of IEC 62282 defines the evaluation methods of typical performances for electric energy storage systems using hydrogen. This is applicable to the systems which use

5 Best Fuel Cell Codes for Home Energy Compliance

Jul 11, 2025 · The five best fuel cell codes for home energy compliance are NFPA 853, IFC Chapter 12, NEC Article 692, ICC-SRCC/ASABE 10-2021, and ANSI/CSA FC 1. These

Understanding the IEEE Standards and Processes

Feb 11, 2021 · The purpose of this article is to introduce the Fuel Cell Industry to the body of standards that can have immediate and relevant impact on fuel

Regulations, Guidelines, and Codes and Standards

3 days ago · The Hydrogen and Fuel Cells Codes and Standards Matrix, maintained by the Fuel Cell and Hydrogen Energy Association, is an up-to-date directory of all codes and standards

6 FAQs about [Fuel cell standards for energy storage]

Why do we need a standard for hydrogen and fuel cell systems?

Because hydrogen and fuel cell systems are complex and will be used in a wide range of applications, many standards development organizations are working to develop codes and standards needed to prepare for the commercialization of alternative fuel vehicle technologies.

What is the hydrogen and fuel cells codes & standards matrix?

The Hydrogen and Fuel Cells Codes and Standards Matrix, maintained by the Fuel Cell and Hydrogen Energy Association, is an up-to-date directory of all codes and standards worldwide dealing with hydrogen, fuel cells, and fuel-cell-related issues.

What is a fuel cell safety system?

Electric safety system: The voltage of fuel cell vehicle can reach as high as 300–600V. A failure of a high voltage may cause an electric shock on a human body. The electric safety system shall provide safe anti-electrocution measures to ensure the personal safety.

How do fuel cell vehicles perform electrical safety tests?

Electrical safety performance test. The fuel cell vehicles mostly use high pressure hydrogen storage containers. A typical high pressure hydrogen storage system consists of a hydrogen storage container, TPRD, check valve, shut-off valve, and piping and fittings between the above components (Figure 4).

How do fuel cell vehicles use hydrogen storage containers?

The fuel cell vehicles mostly use high pressure hydrogen storage containers. A typical high pressure hydrogen storage system consists of a hydrogen storage container, TPRD, check valve, shut-off valve, and piping and fittings between the above components (Figure 4). At the initial state, the shut-off valve is closed.

What are the safety requirements of gtr13 for hydrogen fuel cell vehicles?

The safety requirements of GTR13 for hydrogen fuel cell vehicles aim to minimize the risk of fire, explosion, or leakage from fuel cell systems in vehicle fuel and hydrogen storage system, so as to protect the safety of vehicle drivers and passengers.

Learn More

- Fuel Cell System Energy Storage System

- Energy storage battery solid fuel cell

- Container energy storage system configuration standards

- Construction standards for battery energy storage systems at Vatican communication base stations

- Technical standards for energy storage containers

- Huawei Energy Storage Equipment Standards

- Energy storage cabinet installation requirements and standards

- Portable energy storage in one battery cell

- Common standards for Huawei energy storage systems

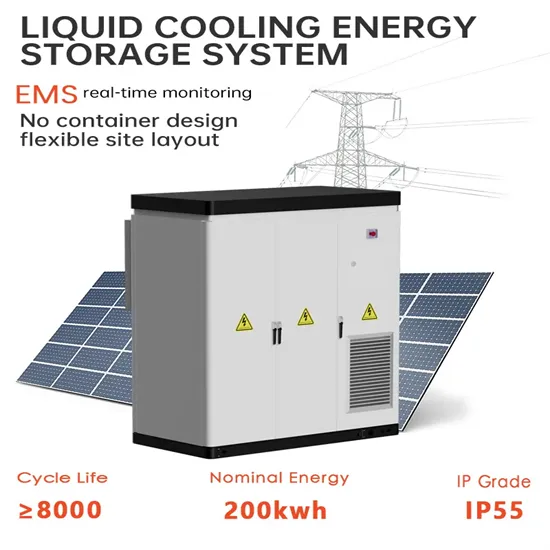

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.