What Amp BMS Do I Need? Sizing Battery Management

What Amp BMS Do I Need? Sizing Battery Management Systems Are you in the market for a Battery Management System (BMS) but feeling overwhelmed by the sheer number of options

Hargeisa fabricant de batteries au lithium pour système de

Système de stockage d''''énergie C&I; Batterie de secours domestique; Fabricant de batteries de loisirs Menu Basculer. Batterie au lithium RV; Fabricant de batterie de voiturette de golf au

What Makes the 200A BMS Lithium Battery Ideal for RVs and

Mar 18, 2025 · The 200A BMS Lithium Battery 51.2V is optimized for RVs and golf carts due to its high energy density, lightweight design, and advanced Battery Management System (BMS). It

8 Best RV Batteries | 2025''s Top Deep-Cycle

Apr 30, 2025 · Deep-dive into these deep-cycles with our expert buyer''s guide to the 8 Best RV Batteries. Dry camping, shore power, AGM, lithium—we cover it

ACOPOWER 12V LiFePO4 Deep Cycle Lithium Battery

13 hours ago · ACOPOWER 12V 100Ah LiFePO4 Deep Cycle Lithium Battery with Built-in 100A BMS, Each Battery Can Support 1280W Power Output, Perfect for Solar, RV, Caravan,

Best Rv House Deep Cycle Battery [Updated On: August 2025]

3 days ago · Walking outside in pouring rain, I realized why a reliable deep cycle battery truly matters—your power can fade at the worst possible moment. After hands-on testing, I saw

Industrial Battery Management System (BMS) devices

Oct 13, 2023 · STSW-L9961BMS Firmware package, containing source code and binaries, with standalone firmware driver and application examples (*) * battery voltage, current and

Test procedure BMS temperature protection

Nov 7, 2017 · It has a BMS that reads this current sensor and potentially communicates with battery management systems at lower and higher levels. Fail-safe BMS1: A fail-safe BMS

D6.7 – Battery Management System Standard

May 25, 2024 · Battery management systems (BMS) can be defined as a safety control system required for managing of individual cells of the battery pack and an entire battery pack. This

How Do Regulatory Challenges Affect RV Battery Safety and

Mar 22, 2025 · Regulatory challenges impact RV battery safety by creating evolving standards that manufacturers must follow. Compliance ensures batteries meet safety, performance, and

Battery Management System (BMS) Essential for RV Battery

Sep 23, 2024 · A Battery Management System (BMS) monitors and manages the performance of your RV batteries, ensuring safe operation. It protects against overcharging and deep

What Are the New Safety Standards for RV Lithium Batteries

Feb 25, 2025 · New safety standards for RV lithium batteries focus on enhanced testing protocols, mandatory labeling, improved installation guidelines, and stricter regulatory compliance to

Key Safety Standards for Automotive & Industrial BMS

We have outlined the important safety protocols and industry regulations that should be considered and complied while designing a robust BMS system for any industry applications

D6.7 – Battery Management System Standard

May 25, 2024 · The analysis of existing standards for battery packs in different applications, and the functional safety standards like ISO 61508 and ISO 26262 for the development of

Review of Battery Management Systems (BMS)

Mar 15, 2021 · The analysis includes different aspects of BMS covering testing, component, functionalities, topology, operation, architecture, and BMS safety aspects. Additionally, current

Battery Management System (BMS) Essential for RV Battery

Sep 23, 2024 · A Battery Management System (BMS) is vital for ensuring the safety and efficiency of RV battery systems by monitoring key parameters like voltage and temperature while

energy storage bms product certification standards

BMS Tutorial Course 2/3: Battery Stack Design for UL 1973 Certification If you are developing a stationary energy storage system, chances are you have already heard of UL 1973 and UL

Safety Standards For Battery Management (BMS)

Dec 25, 2024 · Functional safety standards ensure that safety-related functionality in Battery Management Systems (BMS) is maintained throughout its lifecycle,

What Is a BMS in Batteries? Definition, Functions,

Jun 10, 2025 · A Battery Management System (BMS) is the intelligent controller that ensures batteries are used safely, efficiently, and reliably. Whether you''re

British Standards Institution

Apr 13, 2021 · This standard deals with safety, performance requirement and control parameters of Battery Management System (BMS) for safe working of battery electrical energy storage

What Are the New Safety Standards for RV Lithium Batteries

Feb 25, 2025 · Battery Management Systems (BMS): To monitor voltage, temperature, and prevent overcharging or deep discharge. Proper Labeling: Clear warnings and instructions

6 FAQs about [Hargeisa RV Battery BMS Standard]

What is a battery management system (BMS)?

Battery Management Systems (BMS) are at the heart of electric vehicle (EV) safety, ensuring the efficient and reliable operation of lithium-ion batteries. As batteries become more powerful and complex, maintaining their safety, performance, and longevity is critical.

What are functional safety standards in battery management systems (BMS)?

01. Functional Safety Standards (ISO 26262) Functional safety standards ensure that safety-related functionality in Battery Management Systems (BMS) is maintained throughout its lifecycle, mitigating risks that could compromise the system’s reliability and safety.

What is a BMS battery pack?

and battery environment temperature—can be controlled in the battery pack for BMS safety. BMS can ensure control of these two types of battery temperatures within their safety limit. systems. It allows protection of loss of air conditioning and battery cooling and protects the loss of battery heating controls (BSS).

Does BMS work in a safety battery support system?

operational. BMS active charge control function is inhibited during this process, and BMS the main contactors. In addition, cell overheating with an inhibited battery pack cooling control function should be secured. The objective is to validate the BMS functionality of start-up of safety battery support systems (e.g., fire extinguisher).

What are BMS safety recommendations?

BMS Safety Recommendations BMS includes battery cells, power electronic equipment, controller and monitoring units, and energy management units. Therefore, any abnormality or accident can cause a BMS-related accident. It is critical to take appropriate precautions as a rule for every BMS component.

What are the hazards associated with BMS operation within battery systems?

T able 3presents the potential hazards related to BMS operation within battery systems. T able 3. Operational BMS hazards. 1. Loss of air conditioning and battery cooling (BSS—battery support system). 2. Loss of battery heating controls (BSS). 3. Loss of battery voltage control function (BMS/EMS). 4.

Learn More

- Sierra Leone RV Battery BMS Wholesale

- Tripoli RV battery bms wholesale

- Niamey RV battery bms manufacturer

- Features of Kuala Lumpur BMS battery management power system

- Bms lithium battery customization

- Lead-acid battery BMS industry

- Austrian energy storage lithium battery bms

- Cyprus power battery bms wholesale

- Update BMS battery management system

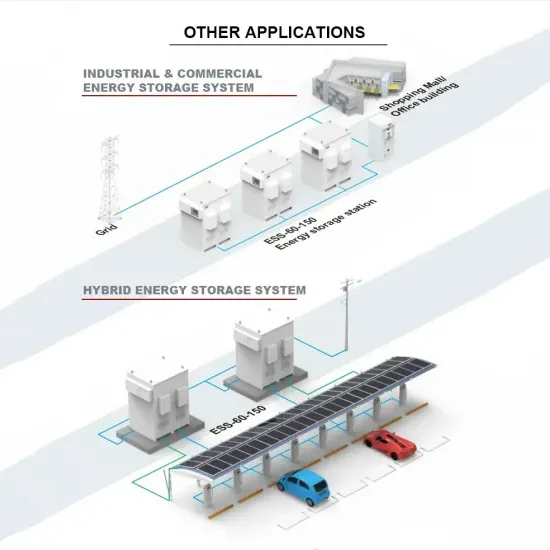

Industrial & Commercial Energy Storage Market Growth

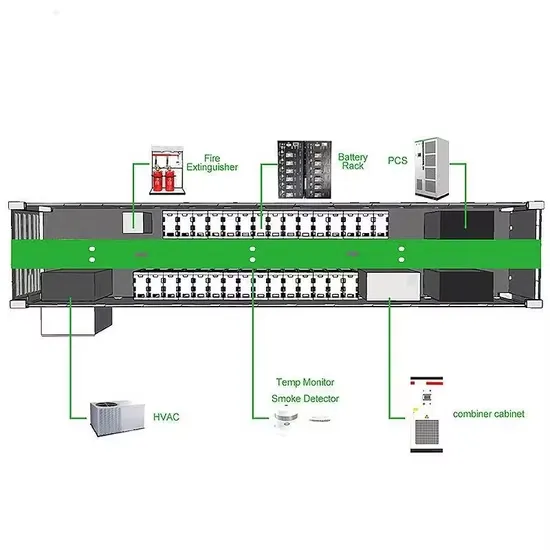

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.