How to Use water pump 12v: Examples, Pinouts, and Specs

A 12V water pump is an electromechanical device designed to move water through pumping action, powered by a 12-volt DC power supply. These pumps are widely used in applications

DC Water Pump Guide: Types, Applications, and Key

May 24, 2025 · A DC water pump is an electric pump that operates using a direct current power supply. Unlike traditional AC pumps that require higher voltage, DC pumps operate on lower

Help with external power with 5v relay | All About Circuits

Feb 6, 2024 · I have a 5v relay and some old laptop charges along with some PC power supplies. Is it possible to use these as external power sources for my projects? I am using a raspberry pi

Can I power this 12v water pump with USB

Mar 30, 2018 · I can actually power the 12v water pump using my power supply. Connect it you yellow wire which is 12v but as I said, I dont want a wall outlet or power supply just to power a

Control a water pump by the ESP32 card

Mar 23, 2022 · A 12V water pump is a type of pump that is designed to run on a 12-volt DC power supply. These types of pumps are commonly used in automotive, marine, and RV applications,

12v dc water pump connection

Nov 21, 2020 · Perhaps you''ve confused it with a power supply, which operates at 220 VAC input and has 12 VDC output. If your pump is surging then it''s quite possible the power supply isn''t

Submersible 3V DC Water Pump Connection

Apr 4, 2023 · Can I use the raspberry pi pico as 3V power supply or do I need an external power supply? Meanwhile I also have an Raspberry Pi Zero W connected, to transport the data I

How to select a power supply for a water pump?

Aug 16, 2020 · There are two important things to remember: 1. You must know the input voltage of your water pump. Most of them are 12V AC and 12V DC. The 12V AC and 12V DC power

external power supply for DC350 water pump?

Jul 28, 2007 · I would like to use an external power supply for my water pump because I am going to set up an external pump and radiator. I know I can mod a cheap computer power supply,

How to Use Water Pump: Examples, Pinouts, and Specs

The water pump is an essential electronic component used to move water from one place to another. It is commonly employed in various applications such as irrigation systems, water

Required voltage and ampere external DC?

May 30, 2022 · Use a 5 V supply because that is the voltage just about everything requires (though pumps generally require higher). Connect it to the "5V" pin

6 FAQs about [DC water pump using external power supply]

What is DC Water Pump?

What is dc water pump? A DC water pump, a vital device in fluid handling, is powered by a DC power supply and serves the crucial functions of transporting and pressurizing liquids.

Will a wall-wart 12V DC Water Pump fit a 24W water pump?

OK, so a wall-wart 12V DC with a 2A output rating would deliver 24W and would fit. Right? How do you calculate a properly sized PSU for a DC water pump? What about "headroom"? Let's assume something blocks the motor. Will a blocked motor increase the power draw and fry my PSU? (okay, my pump is "brushless", but does this make a difference?)

What are the components of a DC Water Pump?

The key components of a DC water pump encompass a motor, pump body, impeller, sealing device, and a sophisticated control system. DC Pump Classification: 1. Brushed DC water pump: In the operation of a brushed DC water pump, the coil and commutator rotate in tandem, while the magnet and carbon brush remain stationary.

How much power does a 12V water pump use?

It will be less than at 12V I would expect around 10W to 14W. you will have to measure amperes to find out. Whatever the water flow is through the pump will also have an effect on the numbers you get. on another pump I saw it was rated with 10W at 12V and 17W at 24V.

Can a 220 volt inverter run a 12 volt pump?

An inverter is typically used to convert 12 volts DC to 110 or 220 volts AC. You can not put 220 VAC into an inverter and get 12 VDC out. Perhaps you've confused it with a power supply, which operates at 220 VAC input and has 12 VDC output. If your pump is surging then it's quite possible the power supply isn't strong enough to run the pump.

Can I use a 3.3V power supply for a pump?

Do not use the pico 3.3V supply for the pump. - motors will produce 'ugly' voltage spikes and should not be powered from same power supply than sensible electronics. - two D, C or AA batteries or chargeable batteries and a suitable battery holder. Old electronics are a good place to find such battery holder.

Learn More

- Outdoor power supply for water pump

- Portable DC variable voltage regulated power supply

- 5g base station external power supply standard

- Portable external power supply for new energy vehicles

- Grenada Portable AC DC Power Supply

- How much current does the external power supply of the base station have

- Is there an inverter in the DC power supply

- What is the minimum DC volt for outdoor power supply

- Eastern European DC Uninterruptible Power Supply Merchants

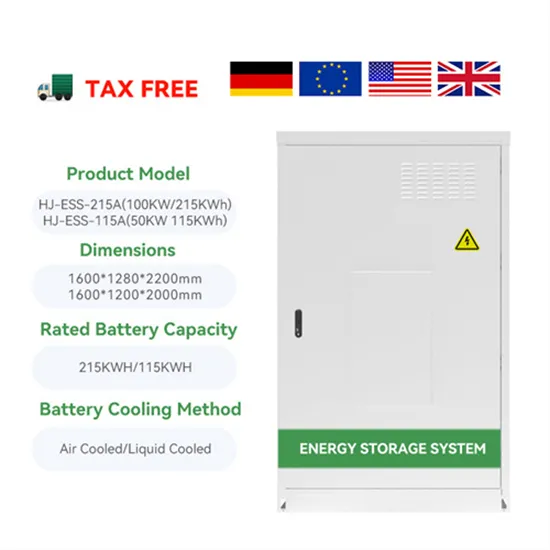

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.