High-Temperature Solar Power Systems

Jun 26, 2022 · High-temperature solar technology (HTST) is known as concentrated solar power (CSP). It uses specially designed collectors to achieve higher temperatures from solar heat

Suitability of various heat transfer fluids for high temperature solar

Aug 1, 2019 · This paper presents a comparative study between various heat transfer fluids suitable for high temperature solar thermal systems. The comparison is made on the basis of

High-Temperature Solar Power Systems | SpringerLink

Jun 27, 2022 · High-temperature solar is concentrated solar power (CSP). It uses specially designed collectors to achieve higher temperatures from solar heat that can be used for

High Temperature Solar Receiver Integrated with a Short Term Storage System

Oct 11, 2016 · Therefore, a solar receiver integrated with a short-term storage system based on high-temperature phase-change materials is proposed in this paper.

High Temperature Solar Concentrators l

Apr 8, 2024 · In order to understand the design of different high temperature solar concentrators, this chapter gives an comprehensive insight into the fundamentals of optical concentration

Compact heat exchangers: A review and future

Jun 12, 2012 · Compact heat exchangers: A review and future applications for a new generation of high temperature solar receivers Qi Lia,b,∗, Gilles Flamantb, Xigang Yuana, Pierre Neveub,c,

High temperature central tower plants for concentrated solar

Mar 1, 2022 · Among the diverse technologies for producing clean energy through concentrated solar power, central tower plants are believed to be the most promising

Port Louis Solar Photovoltaic Power Generation Company

Port Louis, Mauritius is a pretty good location for year-round solar energy production due to its Photovoltaic (PV) technology has witnessed remarkable advancements, revolutionizing solar

High-Temperature Solar Power Systems

Jun 26, 2022 · In contrast to the low-temperature solar devices, high-temperature solar systems achieve temperatures beyond 250 °C and can go up to 3000 °C or more by using

High-Temperature Cavity Receiver Integrated with a Short

Sep 1, 2017 · Dish-Micro Gas Turbines (MGTs) can be promising systems for power production at small-scale by concentrated solar radiation. Several high-temperature

Port Louis Energy Storage Industrial Park: Powering the

Oct 6, 2019 · That''s the Port Louis Energy Storage Industrial Park for you – a 400-acre wonder transforming Mauritius into Africa''s renewable energy laboratory. Nestled between volcanic

Optimization and performance evaluation of a high

May 23, 2024 · This study presents a comprehensive investigation into the development and evaluation of a high-temperature, inexpensive solar air receiver designed for concentrated

The principle of solar power generation in Port Louis

A first 50 kWp solar photovoltaic system as now been successfully installed on the City Hall''''s rooftops, using some of the best components in the solar industry such as 150 Wp thin film

Rapid High Temperature Solar Thermal Biomass Gasification

High temperature biomass gasification has been performed in a prototype concentrated solar reactor. Gasification of biomass at high temperatures has many advantages compared with

Solar radiation in Port-Louis (Guadeloupe)

Jul 15, 2025 · Forecast of solar radiation for 15 days in Port-Louis. Information on the energy that sunlight will generate, useful for systems that take advantage of this energy, such as the solar

Solar energy utilisation: Current status and roll-out potential

Jun 5, 2022 · The point-focus SPT system has received significant attention as it can achieve high working fluid temperature, provide high solar-to-electricity efficiency and employ thermal

High-Temperature Solar Thermal Energy Storage

Nov 6, 2014 · Research at the Solar Energy Research Institute has focused on high-temperature, diurnal storage because of the frequency of use and the potential for conservation of premium

ef3013757 1..9

Mar 30, 2020 · Solar Thermochemical CO2 Splitting Utilizing a Reticulated Porous Ceria Redox System Philipp Furler,† Jonathan Scheffe,† Michal Gorbar,‡ Louis Moes,† Ulrich Vogt,‡ and

Different Temperatures On Planets Within Our

Sep 11, 2023 · Understanding the planets'' temperatures within our solar system is not just a matter of scientific curiosity; it''s a crucial aspect of space exploration

A two-step procedure for the selection of innovative high temperature

Nov 1, 2021 · This work compares with a two-step procedure the performance of different Heat Transfer Fluids (HTF) for high temperature receiver applications (up to 715 °C) in advanced

Hybrid solar high-temperature hydrogen production system

Apr 1, 2000 · A new solar hydrogen production system has been designed and simulated. The system operates at high temperatures with the use of a hybrid solar collector and a high

High temperature systems using solid particles as TES and

Mar 1, 2018 · A lot of development efforts are under way for achieving commercial direct solar solid-particle systems. Solid particle systems for transferring high temperature thermal energy

6 FAQs about [Port Louis High Temperature Solar System]

What is high-temperature LHS?

Hence,high-temperature LHS can make extensive use of high-grade energy (spillage of energy from PV and wind power, Solar energy using CRS) to generate both power and heat simultaneously. The power can be generated directly from thermal energy using thermo-photovoltaic diode and can be treated as a standalone thermal battery.

Can high-temperature LHS produce continuous and cost-effective electricity?

Based on the review, two configurations of high-temperature LHS have been illustrated to produce continuous and cost-effective electricity. The first layout is high-temperature LHS coupled with 3rd generation (Gen) CST and the second one is a standalone high-temperature LHS device with Thermionic-photovoltaic (TIPV) diode. 1. Introduction 1.1.

What is high-temperature latent heat storage (LHS)?

In this context, high-temperature latent heat storage (LHS) using phase change medium (PCM) can be a promising alternative to address the challenges of the variable renewable energy generation with respect to time and space.

What are the challenges faced during numerical prediction of high-temperature LHS?

The challenges faced during numerical prediction of high-temperature LHS are as follows: To model thermal stress developed due to volume change during phase transition To consider radiation heat losses due to high operating temperature Implementation of Stefan condition at phase change interface

What is vast solar CSP?

The Vast Solar CSP design uses a distributed sodium loop throughout the solar array to achieve higher HTF temperatures and higher power cycle temperatures than conventional central tower designs.

How to analyze high-temperature LHS system?

There are experimental results available for melting/solidification of low or medium temperature PCM ( Motahar et al., 2017 ), ( Mehta et al., 2019 ).However, experiments are yet to be performed for high-temperature PCM like silicon. Hence, numerical study is the most preferred method to analyze high-temperature LHS system ( Kant et al., 2018 ).

Learn More

- Port Vila High Temperature Solar System

- Israel high temperature solar system manufacturer

- Japanese high temperature solar system design

- Induction lamp outdoor lighting high power solar lamp

- High quality on grid hybrid solar inverter supplier

- Solar high power gas energy storage cabinet

- High quality solar power station for home producer

- New energy battery cabinet temperature is too high

- Solar air conditioning high power

Industrial & Commercial Energy Storage Market Growth

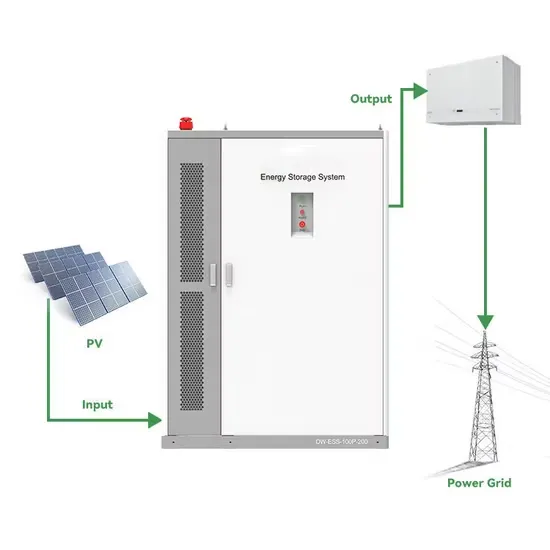

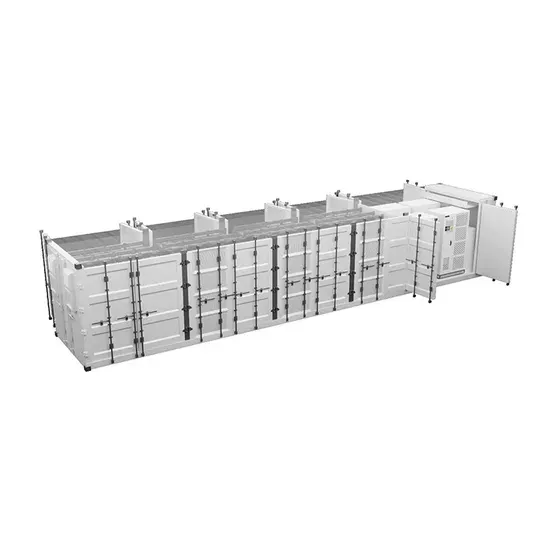

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.