Difference Between Monocrystalline and Polycrystalline Solar

Nov 3, 2023 · Here, we''ll explore the key differences between Monocrystalline and Polycrystalline Solar Panels, that help to choose the best for your solar energy needs.

Comparative Life Cycle Assessment of Photovoltaic Systems

Jul 31, 2024 · With global movement toward renewable energies, photovoltaic technologies are rapidly developing toward a greener electrification and net zero emissions plans, utilizing the

China s multicrystalline solar power grid-connected power generation

A life cycle assessment (LCA) has been performed for the grid-connected electricity generation from a metallurgical route multi-crystalline silicon (multi-Si) photovoltaic (PV) system in China.

Life cycle assessment of multicrystalline silicon photovoltaic

Aug 1, 2016 · Results showed that multi-crystal solar PV technology provided significant contributions to respiratory inorganics, global warming, and non-renewable energy. The

Multicrystalline solar panel power generation test

Why is LCA conducted on multi-crystalline silicon photovoltaic systems in China? LCA is conducted on the multi-crystalline silicon photovoltaic systems in China. Multi-Si production is

PV Crystalox Solar PLC (PVCS)

PV Crystalox Solar is a highly specialised supplier to the world''s leading solar cell manufacturers, producing multicrystalline silicon wafers for use in solar electricity generation systems. Our

Life-cycle impact assessment of renewable electricity generation

May 1, 2020 · Overall, the solar PV plants are found to be much more environment-friendly than other renewable electricity generation systems. These findings will guide investors in installing

Environmental Impact Analysis of Solar Power

Nov 16, 2017 · Abstract – This paper presents the results of the environmental impact assessment into two different technologies for the production of solar power in Thailand. It considers mass

(PDF) Crystalline Silicon Solar Cells: State-of-the

Jun 17, 2012 · Fraunhofer Institute for Solar Energy Systems, Heidenhofstr. 2, Freiburg, Germany Abstract: Crystalline silicon solar cells have dominated the

A review of the factors affecting operation and efficiency of

Jun 1, 2011 · One of the most popular techniques of renewable energy generation is the installation of photovoltaic (PV) systems using sunlight to generate electrical power. There are

Comprehensive investigation of rooftop photovoltaic power

May 3, 2025 · The sensitivity analysis of embodied energy and energy output reveals that the a-Si PV module is the most energy-efficient option compared to other systems, owing to its lower

PV FAQs: What is the Energy Payback for PV?

Sep 13, 2013 · Energy payback estimates for both rooftop and ground-mounted PV systems are roughly the same, depending on the technology and type of framing used. Paybacks for

Multicrystalline photovoltaic panels parallel power

The aim of this review was to present the key challenges of the integration of solar PV power generation into large-scale grids, and the various techniques adopted to enhance the power

Life-cycle assessment of multi-crystalline photovoltaic (PV) systems in

Jan 1, 2015 · The results show that the most critical phase of life cycle of Chinese PV system was the transformation of metallic silicon into solar silicon, which was characterized by high

Life cycle assessment of grid-connected power generation

Jan 1, 2017 · Abstract A life cycle assessment (LCA) has been performed for the grid-connected electricity generation from a metallurgical route multi-crystalline silicon (multi-Si) photovoltaic

Recommended multi-crystalline solar grid-connected

The impact of solar irradiance and temperature on the overall power generation of a grid connected PV system has been studied. 5.8 kW solar PV grid-connected power system, a

China s multicrystalline solar power grid-connected power generation

The SoG-Si production process accounted for more than 35% of total energy consumption and GHG emissions. The environmental impacts of grid-connected photovoltaic (PV) power

A comparative life-cycle assessment of photovoltaic

Jan 1, 2018 · This paper presents a comparative life-cycle assessment of photovoltaic (PV) electricity generation in Singapore by various p-type multicrystalline silicon (multi-Si) PV

Pollutant payback time and environmental impact of Chinese

May 20, 2018 · In order to compare solar energy with a coal-based power generation system, the parameters of the crystalline silicon photovoltaic (c-Si PV) power generation system in China

Monocrystalline VS Polycrystalline Solar PV Modules

Jun 20, 2024 · An increasing number of people worldwide are going green by using solar electricity to power their houses nowadays. According to recent stats, people installed 19GW

A COMPARISON OF THE ENVIRONMENTAL IMPACT OF

ABSTRACT This paper studies the environmental impact of two diferent forms of solar power generation in Thailand – that of multicrystalline silicon solar cells, and that of thin film

Performance evaluation of 50 kWp bifacial multi

Mar 13, 2025 · This study investigated the performance of a 50 kWp bifacial multi-crystalline silicon solar PV system. Simulation results indicate an annual net

Multicrystalline Silicon Solar Cell Manufacturing

Jul 16, 2025 · Multicrystalline silicon remains the cornerstone of photovoltaic device production, benefitting from a balance between performance and cost. The manufacturing process

6 FAQs about [Multicrystalline solar power generation system]

What is the environmental impact of a multi-crystalline silicon PV system?

The environmental impact of the project is about 56–66% of other nations’ PV results. A life cycle assessment (LCA) has been performed for the grid-connected electricity generation from a metallurgical route multi-crystalline silicon (multi-Si) photovoltaic (PV) system in China.

Why is LCA conducted on multi-crystalline silicon photovoltaic systems in China?

LCA is conducted on the multi-crystalline silicon photovoltaic systems in China. Multi-Si production is the most contributor to the energy demand and environmental impacts. Compared to other power generation systems in China, PV system is more environmentally friendly. Areas with higher solar radiation are more suitable for installing PV systems.

Does multi-crystalline silicon (multi-Si) contribute to environmental impact in China?

This study aims to identify the environmental effects associated with photovoltaic (PV) cell made up of multicrystalline silicon (multi-Si) in China by life cycle assessment. Results showed that multi-crystal solar PV technology provided significant contributions to respiratory inorganics, global warming, and non-renewable energy.

How efficient is a 50 KWp bifacial multi-crystalline silicon solar PV system?

This study investigated the performance of a 50 kWp bifacial multi-crystalline silicon solar PV system. Simulation results indicate an annual net AC energy output of 79281.8 kWh and a net DC yield of 84763.7 kWh, corresponding to a performance ratio of 64.47 %, based on a nominal plane of array irradiance of 525330 kWh.

Will global PV capacity increase the demand for multicrystalline silicon (multi-Si)?

An increase in global PV capacity will increase the demand for multicrystalline silicon (multi-Si), which plays an important role in global PV electricity generation (Stoppato, 2008). China plays a leading role in the global multi-Si market.

What is the energy payback time for mono-crystalline silicon (mono-Si) solar cells?

The results showed that the energy payback time (EPBT) for terrestrial mono-crystalline silicon (mono-Si)solar cells that time was 12 years (Hunt, 1976), less than its lifetime. The concerns about the environmental impacts of PV power systems are growing with the increasing use of PV technologies.

Learn More

- Bandar Seri Begawan Solar Wind Power Generation System

- Small solar power generation control system based on PLC

- Principle of solar power generation for mobile base stations

- Japan Osaka rooftop solar power generation system

- Does the solar power generation system use household appliances

- Athens rooftop solar power generation system

- Sun tracking solar power generation system

- Solar agricultural irrigation power generation system

- Malaysia rooftop solar power generation system

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

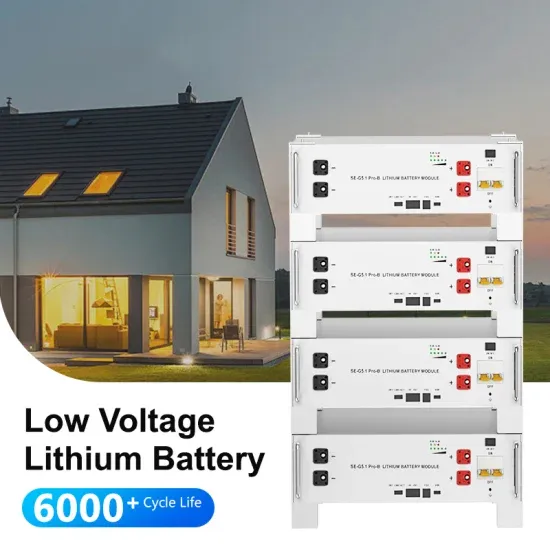

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.