Design and Development of Thermal Management System (Tms) for Battery

Dec 22, 2023 · Maintaining the right temperature range is crucial since lithium battery performance and lifespan are very temperature-sensitive. In this context, this research offers

A review on thermal management of battery packs for

Feb 1, 2024 · For this reason, the TMS must be able to heat the battery cells to withdraw electric energy (essential to power up the electric motor) and reduce the typical lack of efficiency of the

Journal of Energy Storage

Aug 1, 2022 · Hence the thermal management system (TMS) of battery packs for EVs is one of the prominent research areas in recent years. In this study, bibliometric analysis has been

Research progress on the optimization of thermal

In addition to that, lithium-ion batteries play a role in serving as ESS for large-scale grid-level systems that are integrated with sustainable energy sources such as photovoltaic (PV) solar

Research strategy of transition metal sulfide-based

Aug 15, 2025 · This review investigates the application of transition metal sulfide (TMS) anode materials in modern energy storage systems, including sodium-ion batteries (SIBs). Despite its

Recent advancements in redox-active transition metal

Dec 1, 2023 · Supercapacitors (SCs) and secondary batteries (SBs) have been widely used for energy storage purposes, but each has its own limitation such as low ene

Promotion of practical technology of the thermal

May 8, 2024 · The operational temperature of a battery significantly impacts its efficiency, making the design of a reliable Thermal Management System (TMS) essential to ensure battery safety

Review of thermal management system for battery electric

Mar 1, 2023 · BEVTMS mainly consists of air conditioning (AC) system, battery thermal management system (BTMS) and drive motor TMS [2]. These three parts have direct impact

Thermal Management of Battery Energy Storage Systems

Sep 22, 2024 · In the contemporary landscape of renewable energy integration and grid balancing, Battery Energy Storage Systems (BESS) have emerged as pivotal components. This

Designing effective thermal management systems for

Apr 10, 2025 · By capturing real-world behavior virtually, engineers can evaluate the effects that different operating conditions and thermal management strategies have on various design

Review of integrated thermal management system research for battery

Jan 15, 2025 · The integration of thermal management systems (TMS) is a key development trend for battery electric vehicles (BEVs). This paper reviews the integrated

Optimal design and control of battery-ultracapacitor hybrid energy

Nov 10, 2024 · The new synchronized optimizations of the battery-UC HESS design, EMS and TMS are introduced to address this overlooked issue, ensuring the BEVs'' electric ESS power

Advanced Materials for Energy Conversion and Storage 2025

4 days ago · This symposium intends to provide a forum for researchers from national laboratories, universities, and industry to discuss the current understanding of materials

Battery thermal management with thermal energy storage composites

Apr 1, 2020 · This type of batteries generates a large amount of heat, especially during the fast discharge process. Therefore, the absence of an appropriate thermal management system

Battery thermal management systems: Recent progress and

Aug 1, 2022 · The rapid growth in the capacity of the different renewable energy sources in the last decades requires the development of energy storage systems that can accommodate

TMS Thermal Management System for high energy

Oct 20, 2022 · Thermal Management System for high energy storage batteries The MCC TMS is designed to manage high energy storage batteries to a desired temperature while being used

A study on thermal management system of lithium-ion batteries

Nov 1, 2023 · Amid such types of batteries, due to low self-discharge rate, high energy storage density, light weight and longer cycle life, Lithium-ion Batteries (LIBs) are preferred in electric

PRODUCT PORTFOLIO Battery energy storage

Jul 17, 2024 · Battery energy storage solutions For the equipment manufacturer — By 2030, battery energy storage installed capacity is estimated to be 93,000 MW in the United States.1

Efficient Energy Utilization: A Key Role in Battery

Apr 30, 2025 · Battery management systems are critical in optimizing energy storage systems. Gain insight into the benefits of YMIN capacitors, known for

Battery thermal management systems based on nanofluids

Jun 1, 2022 · Compared with diverse methods of energy storage, lithium-ion batteries (LIBs) are sufficient preferable for electrical vehicles (EVs) due to their high energy densities, low-energy

Developments in battery thermal management systems for

Mar 1, 2021 · In this era of a sustainable energy revolution, energy storage in batteries has come up as one of the most emerging fields. Today, the battery usage i

6 FAQs about [Energy Storage Battery TMS]

What is a thermal management system (TMS) in a battery pack?

For instance, the most common design of battery packs is a combination of cylindrical LIBs cells in series and parallel to size up the capacity of the battery pack . However, combining a large number of cells results in rapid temperature rising within the pack itself, and the thermal management system (TMS) plays a serious role .

Why are battery thermal management systems important?

Safety hazards: Overheating may result in thermal runaway or fire, especially in large-scale deployments. For these reasons, effective battery thermal management systems are vital in commercial, industrial, and utility-scale BESS installations. What Are the Main Types of Battery Thermal Management Systems?

Does battery pack design affect thermal management system (TMS) of EVs?

From the past, it was shown that battery pack design would affect the thermal management system (TMS) of EVs. For instance, the most common design of battery packs is a combination of cylindrical LIBs cells in series and parallel to size up the capacity of the battery pack .

How can BMS and EMS improve battery energy storage performance?

Smart integration between BMS and EMS in battery energy storage enables predictive maintenance and optimal operation. Thermal management is not just a safety mechanism—it’s a performance enabler for modern energy storage systems.

Why should a battery pack have a TMS?

Enhanced TMSs, like liquid cooling, efficiently dissipate heat. Additionally, robust battery pack designs with fire-retardant materials and physical barriers isolate potential thermal events. Incorporating rapid shutdown mechanisms and insulation layers further mitigates risks.

What is a battery management system (BMS)?

Lu et al. discussed the diverse aspects of the battery management system (BMS), which encompasses the battery modeling, state-of-charge (SOC) estimation, monitoring of state-of-health (SoH), thermal management, and concerns of safety.

Learn More

- Energy storage cabinet battery rack

- Congo Energy Storage Outdoor Battery

- Battery for energy storage in Guatemala City

- EK Energy Storage Battery Technology Company

- Energy storage battery and capacity

- Long-lasting energy storage lithium battery

- Cameroon Douala battery energy storage box processing and customization

- Battery Energy Storage Framework

- Liquid-cooled energy storage battery cabinet charging

Industrial & Commercial Energy Storage Market Growth

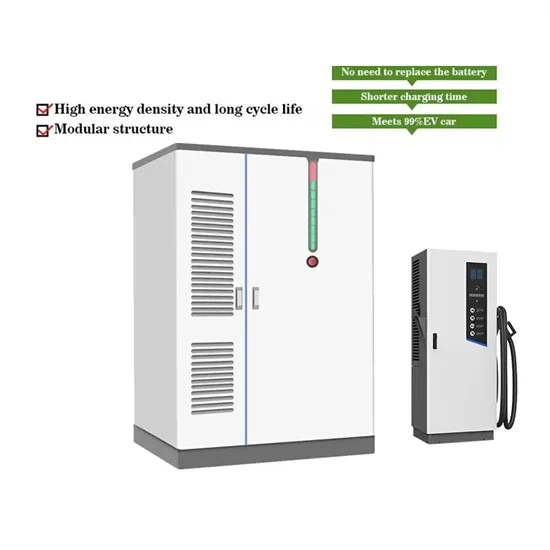

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.