Multifunctional On-Shore Power Systems for Harbors

Sep 23, 2017 · The containers can be con-nected in parallel so that it is easy to enlarge the capacity. The facility''s characteristic control functions include abili-ties to supply power to on

Power Requirements for Refrigerated Shipping Containers | Containers

6 days ago · When installing a refrigerated shipping container (also known as a reefer unit), it''s essential to understand the power supply requirements to ensure safe and reliable operation.

Internal structure of outdoor energy storage power supply

ile power source for your camping and outdoor adventures! Equipped with high capacity batteries, this power supply unit can keep your devices charged and powered throughout the day. It

TIP manual | Power distribution for ports and harbors

fully customizable and integrated power supply solu-tion comprising software and hardware products, sys-tems, and solutions across all voltage levels. TIP per-fectly integrates into

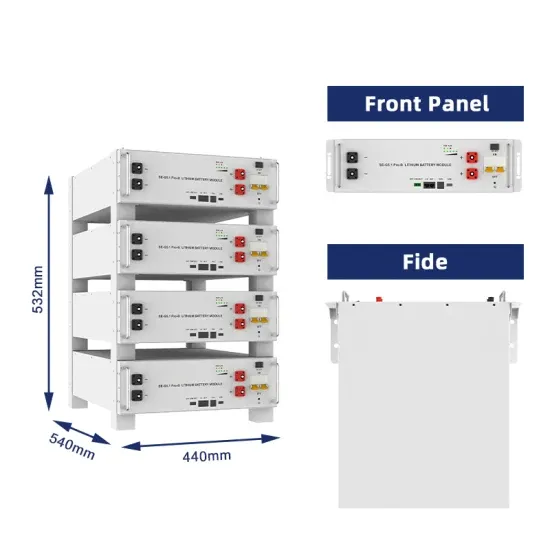

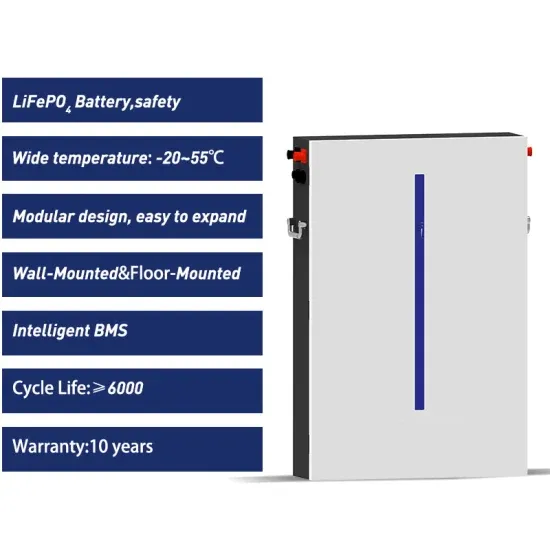

Energy storage power station container structure

The two energy storage power stations are compact in structure design, composed of modules, easy to install, and can be quickly put into use. Stable performance, whether in remote areas

Analysis of an internal structure for refrigerated container: Improving

May 1, 2020 · An improved internal structure is proposed to improve the distribution of cooling capacity in refrigerated container. Firstly, a computational fluid d

What is Portable UPS Outdoor Energy Storage Power Supply?

Portable UPS power supply is a lithium battery UPS designed for outdoor emergencies. It has the characteristics of lightweight, high capacity, and large power. It is easy to carry and can

Reefer Container Power Supply: Your Ultimate Guide to

Reefer containers, or refrigerated containers as they''re known, are a lifeline for industries like food and pharmaceuticals. These specialized units rely on consistent power supply to maintain

Unlocking the Internal Structure of Container Energy

Oct 17, 2023 · a shipping container-sized box humming quietly in a field, holding enough power to light up a small town. That''s the magic of container energy storage – the backbone of modern

What Does the Container Energy Storage System Consist of?

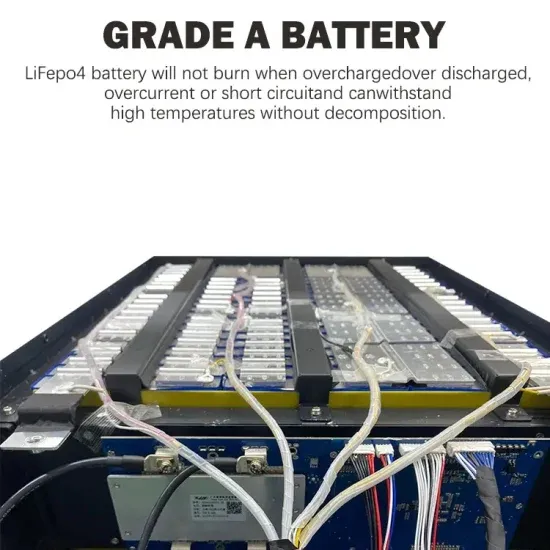

Jul 6, 2023 · Internal structure of containerized energy storage The battery system is mainly composed of battery cells connected in series and parallel: first, several groups of battery cells

Internal structure of container energy storage

As mentioned above, adjusting the tube diameter and internal structure of the container is an effective way to increase the heat transfer area for the improvement of the ICM-TES container.

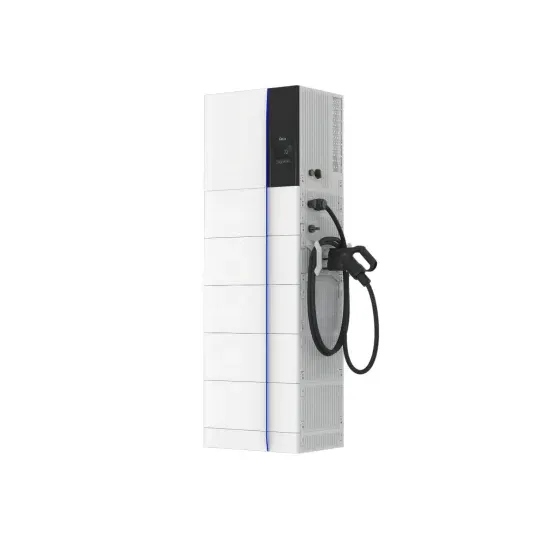

1000 kWh Battery Storage Manufacturer | HT Infinite Power

HT Infinite Power 500kw 1000kwh battery storage systems outdoor container adopts advanced 6S intelligent management technology, including EMS, PCS, BMS, fire protection system,

Containerized Energy Storage

Nov 19, 2019 · CanPower containerized energy storage solutions allow flexible installation in various applications including marine, industrial equipment, shore power, renewable and grid.

What is Container Energy Storage? Applications & Advantages

Mar 7, 2025 · With the transformation of the global energy structure and the rapid development of renewable energy, energy storage technology has gradually become a key factor in supporting

What is a solar energy container and how does it

May 26, 2025 · Another common solar energy container is the solar power box, which is a highly integrated small photovoltaic power generation system that

What is Mobile Solar Power Container

Jul 3, 2025 · A Mobile Solar Power Container is a self-contained, transportable solar energy system built into a shipping container or customized enclosure. Designed for flexibility, rapid

Containerized Energy Storage System: Structure and

With high integration and flexibility, the containerized energy storage system has become an ideal choice in the renewable energy field. From an internal structure perspective, the containerized

professional Outdoor energy storage power supply custom,oem Outdoor

Aug 5, 2025 · **Strong Vibration Resistance and Structural Design:** * The robust structure and reinforced internal components effectively withstand the constant vibration and shock from

Battery Energy Storage Container: Differences

Sep 12, 2023 · Applications: Versatility of Containers and Prefabricated Cabins Applications of Containers: Battery storage containers are suitable for various

The Transformative Power of Energy Storage Containers

Jul 14, 2025 · Multiple applications and customized services Wide application areas The application scenarios of energy storage containers are extremely wide, and they play an

6 FAQs about [Internal structure of container outdoor power supply]

How many power supplies can be mounted in a 40ft container?

Power supplies <300kW can be mounted in only a single 40ft container, while greater powers can be achieved in multiple containers and connected upon delivery. Depending upon specifications, containerized power supplies may be stacked, or located side-by-side. Setup and testing or shut-down and packing can be achieved within a matter of days.

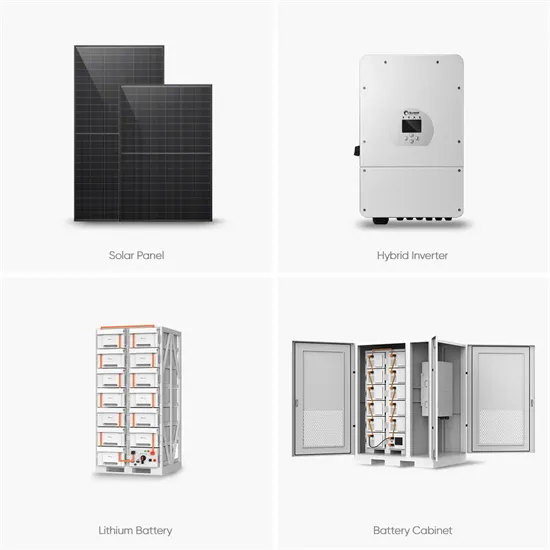

What generating systems can be integrated into a power center?

In addition to the generating units required for safety power supply, more power generating systems such as combined heat and power stations (CHP) and renewable energy sources such as photovoltaic systems, wind turbines, geothermal energy etc. can be integrated into the power center.

Why should you use ISO 6346 container standards?

Use of ISO-6346 container standards allows maximum flexibility. Power supply comes from a cable connection to the grid, or from suitable generators, at low or medium voltages. A wide range of high voltage, CW DC, pulsed or modulated waveform outputs can be provided. The entire system is made to be entirely weatherproof.

What are the main energy consumers of a port?

The main energy consumers of a port are its terminals with STS and reefer containers. They represent approxi-mately 80 % of the total energy demand. The remaining 20 % is consumed by lighting, workshops and other ancil-lary buildings.

What types of power supplies can be provided?

A wide range of high voltage, CW DC, pulsed or modulated waveform outputs can be provided. The entire system is made to be entirely weatherproof. Power supplies <300kW can be mounted in only a single 40ft container, while greater powers can be achieved in multiple containers and connected upon delivery.

How does a port generate energy?

To a minor extent, concepts of inde-pendent power supply and microgrids are implemented. Heat is either generated within the port by burning main-ly fossils such as oil and natural gas, or obtained from the district heating grid. The main energy consumers of a port are its terminals with STS and reefer containers.

Learn More

- New outdoor power supply 3000w container

- Is the container outdoor power supply easy to use

- Container outdoor power supply voltage

- Jamaica custom outdoor power supply manufacturer

- Outdoor power supply with battery

- How is the outdoor communication power supply BESS business doing

- Outdoor power supply 4 kWh ranking

- Electricity to charge outdoor power supply

- New EU outdoor power supply

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.