What are the methods of testing 21700 size Li ion cells?

Jul 30, 2025 · You''ve sourced 21700 cells for your new product, but how can you be sure they perform as promised? Poor cell quality can lead to product failure, recalls, and a damaged

What is the Highest Capacity 21700 Cell

Nov 6, 2024 · So, make sure to verify capacity claims through trusted sources. These advancements in 21700 capacity reflect the rapid development of lithium ion battery cell

Battery Capacity Explained: Why Some 18650 & 21700 Cells

The capacity of batteries, specifically lithium-ion cells like the 18650 and 21700, varies primarily due to their design, materials used, and intended application. Higher capacity batteries can

Heat generation quantification of high-specific-energy 21700 battery

Feb 5, 2021 · In addition, based on the obtained variable specific heat capacity, the heat generation characteristics of the 21700 battery under different operating conditions were

Measurement of thermophysical parameters and thermal modeling of 21,700

Aug 15, 2023 · There is temperature unevenness inside the operating battery, and the internal temperature distribution of the battery has gradually attracted attention. To establish a thermal

Step-by-Step Battery Capacity Testing Procedure

May 23, 2024 · With our step-by-step procedure, you''ll learn how to precisely evaluate battery capacity. Discover key tools, techniques, & best practices for

Scale-Up of PPR Battery Design for 21700 Format Cells

Jan 3, 2024 · Achieve PPR battery pack using 21700 cells leveraging lessons learned from 18650 PPR battery designs Provide direct comparison of 18650 M3 battery to 21700 M5 battery with

Measurement of thermophysical parameters and thermal modeling of 21,700

Aug 15, 2023 · To establish a thermal model of the 21,700 cylindrical battery that can reflect the internal temperature distribution, thermophysical parameters including anisotropic thermal

Ampace 21700A Battery Data, Model and Report

2 days ago · Get everything you need for the lithium-ion battery cell Ampace 21700A: Extensive measurement data in the total operation regime, a high-precision, physical battery model with

Thermal Characterization of a Cylindrical Li-ion Battery Cell

Dec 14, 2020 · Keywords: Thermal conductivity, Thermal characterization, Specific heat capacity, cylindrical cell, Li ion battery cell, Isothermal Heat Conduction Calorimeter, Tesla cylindrical cells.

Thermal parameters of cylindrical power batteries: Quasi

Oct 11, 2022 · A B S T R A C T In this work, a new quasi-steady state heat guarding measurement method for the thermophysical parameters of cylindrical batteries is proposed.

Low-effort determination of heat capacity and thermal

Oct 1, 2021 · High-fidelity simulations of lithium-ion cells describing fast charging or safety-critical events often rely on precise thermal parameters. Usually, the determination of cell parameters

Innolith High Energy 21700 (A) Battery Data,

6 days ago · Get everything you need for the lithium-ion battery cell Innolith High Energy 21700 (A): Extensive measurement data in the total operation regime,

What Are 21700 Batteries?

Aug 12, 2025 · 21700 batteries are cylindrical lithium-ion rechargeable cells measuring 21mm in diameter and 70mm in length. Offering higher capacity and energy density than the popular

Your Ultimate Guide to DeWalt Batteries Using 21700 Cells

Mar 30, 2025 · 21700 cells are cylindrical lithium-ion battery cells that measure 21mm in diameter and 70mm in length. These cells are designed for high-capacity applications and typically offer

Thermal management of 21700 Li-ion battery packs:

Jan 5, 2024 · Due to its increased cell size, LIB 21700 (Lithium-ion battery) format has surpassed the existing formats as it offers larger capacity and higher energy density. However, the battery

What are the methods of testing 21700 size Li ion cells?

Jul 30, 2025 · You can measure the cell''s voltage to determine its state of charge, but you cannot test its true capacity (Ah) or internal resistance (mΩ), which are critical performance metrics. A

Ultimate Guide: Testing 18650 and 21700 Cells for Battery

Learn how to thoroughly test 18650 and 21700 cells before assembling battery packs. Expert guide on equipment, procedures, and data analysis for optimal performance.

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Ultimate Guide: Testing 18650 and 21700 Cells for Battery

Testing individual 18650 and 21700 lithium-ion cells before assembling them into a battery pack is crucial for ensuring optimal performance, safety, and longevity of your final product. This

6 FAQs about [Measure the capacity of 21700 battery cells]

What is a 21700 battery?

The 21700 battery is a cylindrical lithium-ion battery with a diameter of 21mm and a length of 70mm. It offers a nominal voltage of 3.7V and a capacity of up to 5,000mAh, making it a powerful and efficient energy source. Its energy density ranges between 250 Wh/kg and 300 Wh/kg, depending on the chemistry.

Should you test 18650 & 21700 cells before assembling a battery pack?

the ultimate guide to testing 18650 and 21700 cells before battery pack assembly Testing individual 18650 and 21700 lithium-ion cells before assembling them into a battery pack is crucial for ensuring optimal performance, safety, and longevity of your final product.

How much does a 21700 cell weigh?

The 21700 cell weighs approximately 60–70 grams, depending on the manufacturer and specific chemistry. While slightly heavier than the 18650 cell, this weight increase is justified by its higher capacity and energy density.

What is the energy density of a 21700 battery?

The 21700 battery utilizes advanced lithium-ion chemistry, which provides a balance between energy density, safety, and longevity. Depending on the specific chemistry, such as NMC or LCO, the energy density of the 21700 ranges from 250 Wh/kg to 300 Wh/kg.

Can a 21700 cylindrical battery reflect internal temperature distribution?

To establish a thermal model of the 21,700 cylindrical battery that can reflect the internal temperature distribution, thermophysical parameters including anisotropic thermal conductivity and specific heat capacity are tested through experiments. The thermal model includes the heat generation part and heat transfer part.

Does a 21700 battery have a higher specific volume heat generation power?

In addition, based on the obtained variable specific heat capacity, the heat generation characteristics of the 21700 battery under different operating conditions were analysed. The results showed that this battery has a higher specific volume heat generation power compared with the pouch-type batteries reported in the literature.

Learn More

- 21700 battery cell capacity parameters

- 21700 Maximum battery capacity

- Large 21700 battery cells

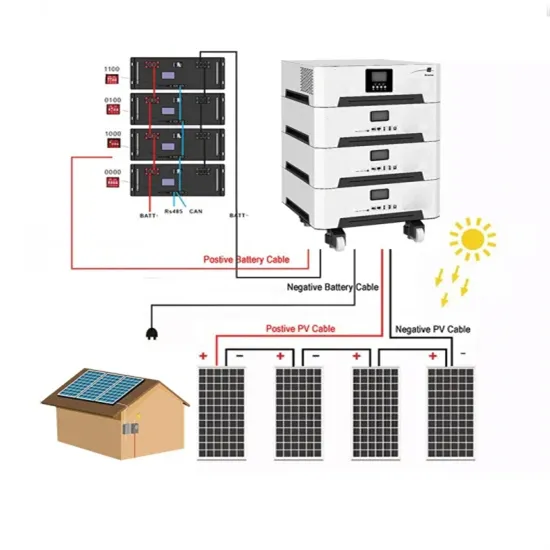

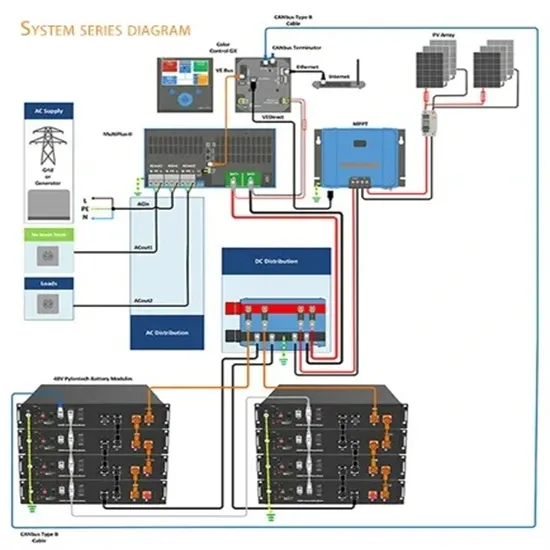

- About the battery capacity selected for the inverter

- Telecom Energy Storage Clean Energy Storage Cabinet Battery Capacity

- Lithium battery pack increases capacity

- Single battery capacity of energy storage power station

- Battery capacity for energy storage

- Lithium battery pack has low capacity

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.