How Long Will a 200W Solar Panel Take to Charge a Battery?

In ideal situations, a 200W solar panel generates 200 watts an hour. 12V 100ah is 1200 watts, so it would take 6 hours for the panel to charge 1200 watts into the battery (200 x 6 = 1200).

Solar Panel Output: How Much Power Can You Expect?

Aug 18, 2025 · Learn how much power a solar panel produces and what impacts output, from panel type to sunlight exposure, to help you plan your solar investment.

What Will a 100 Watt Solar Panel Run? Here is

Feb 1, 2025 · A 100W solar panel that acquires 8 hours of sun exposure each day will generate nearly 1 kWh per day. That means a 100 watts solar panel output

Solar Panel Watts Per Square Foot: ''We (Finally) Did The Math''

2 days ago · Alright, a lot has been said about solar panel watts per square foot. Everybody agrees this is a very important specification. There is a lot of disagreement on how many watts

How Many kWh Does A Solar Panel Produce Per Day?

2 days ago · For 1 kWh per day, you would need about a 300-watt solar panel. For 10kW per day, you would need about a 3kW solar system. If we know both the solar panel size and peak sun

How Much Power Does a Solar Panel Produce? By Wattage, KW Hours

Oct 3, 2024 · Simply put, the amount of energy that solar panels can produce is typically measured in watts. This is a unit of electrical power that is often seen as the universal

How Many Watt Solar Panel To Charge 12 Volt Battery:

Oct 25, 2024 · Unlock the power of solar energy with our comprehensive guide on how many watts are needed to charge a 12-volt battery. Learn about different solar panel types, key

How to Calculate the Output of a Solar Panel (with Examples

May 17, 2025 · Solar panels are a great way to generate clean energy and save on electricity bills. But how much energy does a solar panel actually produce? In this guide, we''ll walk you

Watts to Watt-Hours: Calculator for Power Stations and Solar Panels

Nov 18, 2023 · This blog post delves into the essentials of watts to watt-hour conversion. We provide a handy watts to watt-hour calculator and how to apply that information when choosing

Solar Panel Charge Time Calculator For 12V

5 days ago · Using this solar panel charge time calculator, we have calculated charging times for various sizes of batteries (with various solar panel sizes) at

How Long Does a 100W Solar Panel Take to Charge a Battery?

A 100 watt solar panel can power mobile devices and run small appliances in homes, RVs and other locations. But is it enough to charge a 12V battery? And how long will it take? We will

Solar Panel Amps Calculator (Watts to Amps) –

Mar 3, 2023 · How to use this calculator? Solar panel output: Enter the total capacity of your solar panel (Watts). Vmp: Is the operating voltage of the solar

Solar Panel Output Calculator

Jun 14, 2025 · Solar panel output is the amount of electricity a panel generates under specific conditions, typically measured in watts (W) or kilowatt-hours (kWh) over time. The output

How Many Watts From a Solar Panel Does It Take to Charge a 12

Apr 25, 2021 · In this short guide, we''ll tell you how many watts it takes from solar panels to charge a 12-Volt battery. The longer solar panels are exposed to the sun, the more battery-life

Solar Panel Output Calculator

Mar 3, 2023 · Use this solar panel output calculator to find out the total output, production, or power generation from your solar panels per day, month, or in year. Also, I''m gonna share

How Many Watts Does a Solar Panel Take in 12 Hours A

Confused? Think of it like this: even if the sun shines for 12 hours, effective energy generation is lower due to angle and intensity changes. Panel Wattage: A 400W panel generates 400 watts

Solar Panel Charging Calculations of a Battery

Sep 14, 2022 · A 12-volt lithium-ion battery, on the other hand, takes 4.6 hours to charge from a 100-watt solar panel. It will help you save money on power and

6 FAQs about [How many watts does a solar panel take in 12 hours]

How many watts a day can a solar panel produce?

On average, you can expect: Assuming 5 peak sun hours: 100W × 5 hours = 500 watt-hours (0.5 kWh) per day. In optimal conditions: The panel may produce up to 600-700 watt-hours (0.6-0.7 kWh) daily. In less favorable conditions: The output could drop to as low as 300-400 watt-hours (0.3-0.4 kWh) per day.

How much energy does a 100 watt solar panel produce?

The daily energy production of a 100-watt solar panel is influenced by the amount of sunlight it receives. On average, you can expect: Assuming 5 peak sun hours: 100W × 5 hours = 500 watt-hours (0.5 kWh) per day. In optimal conditions: The panel may produce up to 600-700 watt-hours (0.6-0.7 kWh) daily.

How much sunlight does a solar panel produce a day?

Before solar panels are sent out onto the market, they are exposed to 1,000 watts of sunlight per square meter. We refer to this as peak sun hour, and the manufacturers concluded that the amount of daily peak sun hours would differ worldwide. Solar panels produce more electricity in places that have greater peak sun hours.

How many kWh does a 250 watt solar panel produce?

Typically, a 250 watt solar panel running at its maximum efficiency for 7 hours a day can provide you with 1.75 kWh of output. Again, it will depend on the sunlight and the positioning of the panel. Dive into further reading on the pros and cons of solar energy to determine the average solar panel output that can meet your needs.

What is solar panel output?

Solar panel output is the amount of electricity a panel generates under specific conditions, typically measured in watts (W) or kilowatt-hours (kWh) over time. The output depends on: Use our interactive calculator below Here’s the basic formula to calculate solar panel output per day: Where:

How many solar panels do you need per day?

In California and Texas, where we have the most solar panels installed, we get 5.38 and 4.92 peak sun hours per day, respectively. Quick outtake from the calculator and chart: For 1 kWh per day, you would need about a 300-watt solar panel. For 10kW per day, you would need about a 3kW solar system.

Learn More

- How many watts can a 12 volt solar panel hold

- How big a solar panel should I use for 500 watts

- How many watts are there in a 2-ampere solar panel

- How many watts does a solar 390 panel have

- How many watts does a 21w solar panel produce

- How many watts of electrical appliances can a 100w solar panel power

- How many watts of voltage can a photovoltaic panel output

- How many watts of solar panels can be connected in parallel

- How big a solar panel can drive a 3w water pump

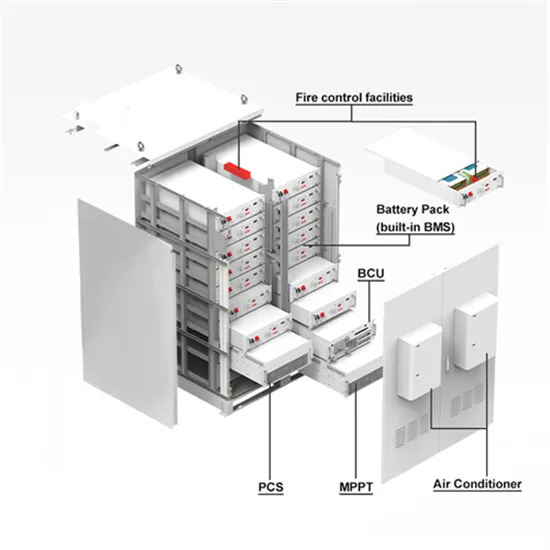

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.