Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · A failure of growing importance is the defect in the glass layer (s) of glass-glass PV modules. In this research, an experimental glass repair technique for glass-glass PV modules

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Weathering of float glass can be categorized into two stages: "Stage I": Ion-exchange (leaching) of mobile alkali and alkaline-earth cations with H+/H3O+, formation of

NGA Presents Updated Resource on Glass Properties

Mar 28, 2025 · NGA has published an updated Glass Technical Paper (GTP), FB39-25 Glass Properties Pertaining to Photovoltaic Applications, which is available for free download in the

光伏玻璃_百度百科

光伏玻璃是太阳能光伏组件的核心封装材料,主要分为晶体硅光伏玻璃(含单晶硅、多晶硅)和薄膜光伏玻璃两大类 [1]。其主流产品包括超白压延玻璃与AR镀

Multi-objective evolutionary optimization of photovoltaic glass

Nov 1, 2023 · Optimized results of low-E semi-transparent amorphous-silicon photovoltaic glass applied on the façade show that the spatial daylight autonomy is increased to 82% with

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

Carbon footprint and environmental impact of China''s PV

Aug 1, 2025 · Quantifying the carbon footprint (CF) and potential value for environmental impact (PVEI) of photovoltaic (PV) production is critical for achieving ca

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · 1. What is solar photovoltaic glass?Solar photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by

Development of low-temperature thermal

The recycling method for thermal decomposition of photovoltaic modules is a recycling method that can completely remove EVA, which is a sealing material, and can neatly separate the

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · 1.1.7 Summary The factors determining the performance of crystalline silicon solar photovoltaic cells are various factors related to the conversion efficiency of light energy. The

Advances in Antireflection Coatings on Photovoltaic Glass

Antireflection coatings (ARCs) can effectively suppress the loss caused by the interfacial reflection. To some extent, it is necessary to fabricate ARCs on the surface of PV glass in PV

Performance Analysis of a Hybrid Thin Film Photovoltaic

May 24, 2022 · In this study, we have investigated a hybrid thin film PV vacuum glazing called: ''PV VG-4L''. The glazing involves an integration between a thin film PV glazing with a double

NGA updates resource on glass properties for photovoltaic

Apr 1, 2025 · NGA volunteers update Glass Technical Papers (GTPs) through the systematic review ballot process on a 5-year cycle. Among structural materials, glass has many

SCHOTT® Solar Cell Cover Glass

Nov 7, 2022 · While photovoltaic solar cells are central to efective spacecraft function, radia-tion in space can gradually degrade those cells, reducing their eficiency. Solar Glass 0787 and Solar

Microsoft Word

Aug 17, 2011 · Abstract Solar photovoltaic glass is direct to the kind of glass, which is apply to the solar module and has a higher transmission or selectively transmission than normal glass.

Effect of Highly Reflective Glaze on Fracture Strength of

Abstract: Highly reflective glaze is commonly applied to solar photovoltaic glass to improve photovoltaic conversion efficiency. However, their impact on the fracture strength of solar

Advanced Energy and Sustainability Research

Jan 26, 2025 · Second, compared to the CF-fabricated devices, the XY-fabricated devices had a narrower distribution in all cases, demonstrating an increased processing window with

Performance of prototype tandem UV filter and organic

Jun 1, 2023 · The PV glass prototype is developed within the Tech4win project [28] and it consist of a tandem structure of organic photovoltaic (OPV) cell [29] and PV active UV filter [30].

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

6 FAQs about [Photovoltaic glass cf]

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

Does flat glass improve photovoltaic (PV) panel efficiency?

Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36]. Based on in-depth analyses of market size, trends, and growth projections. Table 1. Flat glass market. augmented reality and advanced display technologies.

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

Why is Solar Photovoltaic Glass so popular?

With global attention on environmental protection and energy efficiency steadily rising, the demand for solar photovoltaic glass in both commercial and residential construction sectors has significantly increased. The desire to reduce energy costs and carbon footprint has driven the widespread adoption of solar photovoltaic glass.

How can we improve the efficiency of photovoltaic (PSC) systems?

In this manner, we can facilitate a more effective integration of PSCs into our daily lives. The accumulation of pollution and any kinds of contamination on the glass cover of the solar cell affects the efficiency of the photovoltaic (PV) systems.

Why is glass used in PV cells?

Glass mitigates these losses by functioning as a protective layer, optical enhancer, and spectral converter within PV cells. Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency.

Learn More

- Does photovoltaic glass require accessories

- Prague 300W photovoltaic glass price

- West Asia photovoltaic glass manufacturer

- The impact of Bhutan s photovoltaic glass production reduction on

- 3d glass and photovoltaic glass

- External glass curtain wall photovoltaic power generation

- Sao Tome and Principe Photovoltaic Glass

- Photovoltaic glass aluminum

- Mauritius Glass Photovoltaic Module Sales

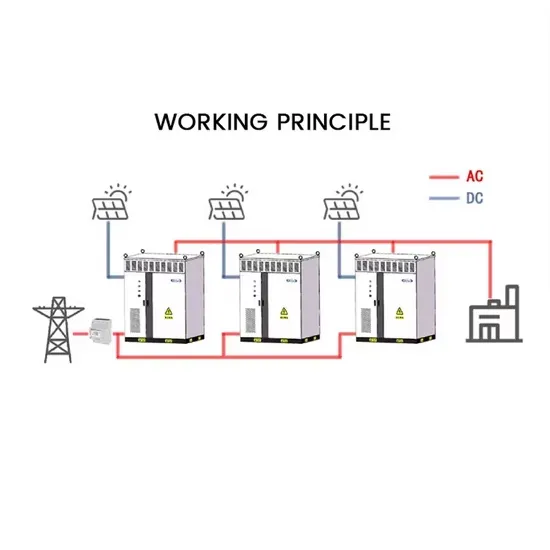

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.